New belt cleaner design reduces cost of ownership

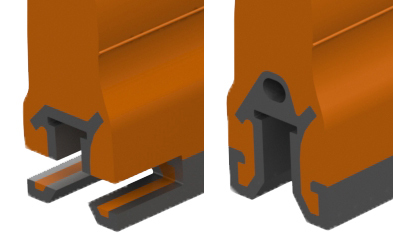

Martin Engineering from Neponset, IL/USA has engineered a new conveyor belt cleaner that contains a smaller total volume of urethane, while maximizing the usable area. It is produced in a streamlined process that allows the manufacturer to reduce the purchase price and overall cost of ownership. By minimizing the non-consumable portion of the blade, the heavy-duty primary belt cleaner delivers the same performance and durability as the model it replaces, while reducing the amount of urethane going to landfills. Manufactured with Martin Engineering’s “CARP” (Constant Angle Radial Pressure) technology to maintain the most efficient cleaning angle throughout its service life, the Martin® QB1 Cleaner HD features a no-tool replacement process that can be performed safely by one person in less than five minutes.

“We’ve simplified the manufacturing process and also re-engineered the blade itself,” explained Global Engineering Manager Paul Harrison. “The new profile will be less complex to produce, and because it can be roll formed or manufactured on a press brake, it will be easier to source throughout the world from any Martin Engineering manufacturing site,” he said.

The reduced weight will also facilitate easier blade replacement, and the one-pin mounting system helps reduce downtime for maintenance. To replace the QB1, maintenance personnel simply pull the locking pin, unclamp the bracket and slide the blade out of the mainframe. The new precut blade is slipped onto the square mainframe and clamped.

CARP technology is exclusive to Martin Engineering, designed to keep the blade at a consistent angle and pressure against the belt. Typically set at about 13.8 kPa for the QB1 HD, the low blade-to-belt pressure helps protect the belt, splice and cleaner itself. As the blade wears, neither the surface area nor the angle is compromised, ensuring maximum performance throughout its life.

To introduce material back into the product flow, the QB1 HD is installed on the face of the head pulley. On a dual cleaner system, the new pre-cleaner is installed immediately in front of the secondary cleaner. For applications involving enclosed pulley chutework, Martin Engineering recommends that one of its steel inspection doors be installed.

The redesigned cleaner was engineered under the company’s EVO philosophy, which re-examines every aspect of component design and function to achieve greater efficiency and fugitive material control. In addition to its cost advantages, the QB1 HD features a mainframe that has been rotated 45 degrees to shed dust and spillage. The urethane formulation can accommodate belt speeds of up to 900 fpm (4.6 m/sec) and service temperatures of -40 °C to +70 °C.

The QB1 HD is available in lengths of 457-2438 mm and can also be ordered in 3.05 meter slugs, allowing distributors or customers to cut to length for increased versatility. This design also features a simpler cut-to-length process. Instead of keeping a number of different blade sizes in inventory, distributors and customers can stock the shortest section and cut to length as needed.

Paul Harrison said that the same type of re-design can be applied to the company’s other belt cleaners, hinting at the opportunities for future product development. “We are always looking for ways to reduce our environmental footprint,” Harrison concluded. “The fact that innovation is leading the way to a lower cost of ownership and reduced waste indicates that the bulk handling industry and environmentalism can work hand-in-hand.”

//www.martin-eng.com" target="_blank" >www.martin-eng.com:www.martin-eng.com