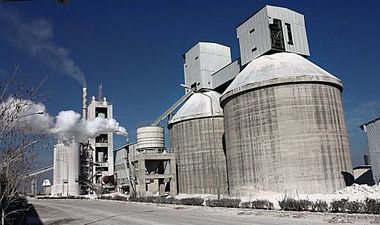

New control station for white

and grey cement production

Back in 2008, some important decisions were being made at Dyckerhoff headquarters in Amöneburg. One such decision – following the discontinuation of grey clinker production – was to sustainably expand the production of white cement. Dyckerhoff has been producing white cement in Amöneburg since 1931. So, the Dyckerhoff Weiss brand was refined and improved with target-group orientation. Special varieties were created for different areas of application to fully satisfy the needs of individual customer groups. The ensuing investments were therefore not confined to merely expanding the production of white cement, but also included measures to further pursue the aforementioned concept of product differentiation. Within the Dyckerhoff Group, the Amöneburg and Göllheim plants belong to the Group’s “South” division, with a combined grey binder volume of over 1.1 million t.

State-of-the-art program and process technology

As a result, the operational infrastructure had to be accommodated to the new set of conditions. To that end, three vacant workshops were repurposed to house a new control center and laboratory, all on one level. Now, those bright and friendly rooms contain a modern control room that is perfectly tailored to the companies’ needs, with maximum functionality and ergonomics. It serves as an optimal platform for centrally monitoring and controlling the cement plant’s various processes. Numerous best-available, semi-circular flat screens displaying the entire plant, from the raw mill and fuel stores to the rotary kiln and cement mills and on to the loading station, give the employees quick access to all relevant data via a process control and video monitoring system, so they can quickly intervene directly in operational processes and implement any necessary corrective measures. For that purpose, Amöneburg is now equipped with the most advanced digital programming and process technology available. Also, the new control room is ideally located in the immediate vicinity of the production area, between the offices of the shift supervisor and the laboratory manager, the latter of whom is responsible for quality control. It is also important to note that every white-product vehicle leaving the factory is “sampled” beforehand according to an individual set of customer-tailored inspection methods and criteria.

Investments in product optimization and environmental protection

Sizable sums have also been invested in the areas of production optimization and environmental protection. In particular, the increasing use of alternative fuels requires increasingly complex management of the clinker production process. Due to the stringent requirements for the use of alternative fuels in white cement production, a new fuel plant was installed at a cost of roughly € 1.3 million and, finally, the existing conventional filter system was replaced with modern fabric filter technology (cloth filters). This investment, amounting to nearly € 2.5 million, not only greatly reduces dust emissions, but also provides noise control, thus avoiding conflicts with neighboring residents. The much stricter limit values for NOx that will come into force on 01.01.2019 have also been complied with in advance at the Amöneburg plant, i.e., since early last June. Yet another investment has further optimized the processing of raw materials for white cement production. This includes new storage and dosing options adding up to € 1.4 million in recent years. In addition, around half a million euros was invested in the control of raw material quality via modern expert systems. Even before the cement is delivered, the customers receive all relevant technical details concerning the consignment. That way, they are always able to compare the current product data with the agreed quality parameters. This form of collaborative partnership engenders security and trust and is appreciated by domestic and, increasingly, foreign customers alike.

//www.dyckerhoff.com" target="_blank" >www.dyckerhoff.com:www.dyckerhoff.com