New drilling equipment – soft and hard

At Conexpo-CON/AGG 2014, held in Las Vegas, Nevada/USA from 04.-08.03.2014, Sandvik Construction unveiled two newly developed tools for drilling.

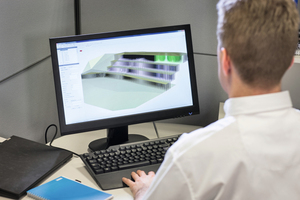

1 Sandvik Driller’s Office

The first tool from the Stockholm/Sweden based international company, with the drilling equipment being developed in Tampere/Finland, is a groundbreaking practical software tool for surface drilling process management, the Sandvik Driller’s Office (Fig. 1). The advanced tool is a friend to anyone who works with surface drilling management, in particular in quarrying applications, as it helps simplify the whole process, as well as managing it efficiently. Thus, the software is a surface drilling planning and data management tool. It covers drill plan design, drilling data management and reporting. Driller’s Office follows the logic of the job site and features clear and simple visualizations of the drilling pattern and terrain models in 3D, greatly helping the planning process.

Sandvik Driller’s Office has been designed with the user in mind. Introducing new kind of flexi-bility and adjustability, it is an easy-to-learn and easy-to-use tool, as it features a drill plan wizard (DPW) for quick creation of basic drilling plans, and a drill plan editor (DPE) for creating more advanced plans. In DPE, hole positions, floor level, inclination, direction and many more factors, can be adjusted independently as needed.

In addition, instead of utilizing a mere default bench shape and form as in standard planning tools, Driller’s Office allow those to be adjusted in order to correspond to the actual existing shapes and forms. A measurement tool and specific markers define the correct spot to start drilling. Thus separate measuring and marking is not needed at the site which saves time and money.

The drilling process is further enhanced with the data management features of the Driller’s Office. The tool collects drilling plans and drilling data to a single project file. All the information on realized drilling results is available as real time feedback to the planning process. Adjustments to the existing plans are designed to be simple. As the result of efficient planning based on exact measuring and real time feedback, drilling accuracy and hole quality will be much improved. Thus blasting results will also be improved, translating into considerable savings in time and money, as well as improved job site safety. Communications to and from the rig are handled over a mobile data connection.

Sandvik Driller’s Office also includes reporting tools: reports on drilled hole coordinates, drill plan and drilling are available. It is available for all TIM3D-ready surface drills.

2 The new Sandvik Ranger DX800

The second tool is a new and improved version of the former bestselling Ranger-series of surface top hammer drill rig. The new version, Sandvik Ranger DX800 (Fig. 2), combines the long heritage of outstanding surface drill rigs with the latest drilling innovations and has a significantly smaller appetite for fuel. The modern outlook of the new Ranger DX800 will make it even more exceptional.

Known by their former name, Ranger, Sandvik’s DX series surface top hammer drill rigs all feature a revolving superstructure enabling large drilling coverage from the standard 17.6m2 (189ft2) to a USA standard 26.4m2 (248ft2). While able to rotate, the rigs stability is guaranteed thanks to its innovative structure, keeping counterweight at all times on the opposite side of the boom. In addition to these, the rig features, for example, a THC700 drilling control system that automatically adjusts to changing rock formations and sends an optimal amount of power to the rock. This has been designed to ensure smooth rotation, solid rock contact and fast penetration in different rock conditions.

Carrying the names of the renowned Rangers and the Sandvik DX rigs, the new rig has a great deal to deliver. Designed to meet the needs of modern day surface drilling, the Ranger DX800 brings along one of the most important qualities: being low in fuel consumption. As everyone around the world is continuously aiming at improving energy efficiency, low fuel consumption can be considered a distinguishing feature. Thus, the new Ranger DX800 is no exception to this rule. The new rig will significantly reduce operating costs that are achieved with a new advanced eco-package and engine RPM adjustment. Another enhancement is improved tramming force, which has increased by over 10 %.

Ranger DX800 is equipped with a low-consumption and low emission Tier IV Final CAT 7.1 Engine (168 kW, 225 hp). Utilizing DPF technology with a common rail-type fuel injection system, it is able to produce high torque with lower RPM level. In the Ranger DX800, the standard level of 1800 rpm has been dropped to 1600 rpm, resulting in significantly reduced fuel consumption. On average, this translates into 5.5 liters/1.45 gallons less fuel consumed per active hour.

While fuel consumption has been significantly reduced, the new Ranger drill rig still promises to provide pertinent power for drilling tasks – even in tough ground conditions. Coming with the well-proven rock drill HL810T as a standard, it can also be upgraded by changing it to a high frequency HF810T drill.

//www.construction.sandvik.com" target="_blank" >www.construction.sandvik.com:www.construction.sandvik.com