New membrane product line PM-Tec®

For more than 40 years now, BWF Envirotec has been producing innovative filter media for industrial filtration. With the new PM-Tec® product line the company from Offingen, Germany is extending its product portfolio, offering new filter media specifically used in filtration of minute dust particles. The name for the new product line originates in the English term for fine dust, “particulate matter”. This term was coined at the end of the 1980‘s by the US Environmental Protection Agency (EPA), which introduced in the form of the so-called PM standard a classification in measurement of fine dust. This categorization is now used internationally for classification of fine dust.

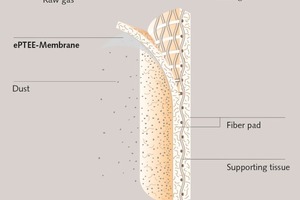

The product line consists of a carrier medium made of needlona® needle felt or fiberglass fabric on which a membrane produced from expanded Polytetrafluorethylene (ePTFE) is laminated. The membrane therefore possesses characteristics which are optimally suited for use in industrial fine dust filtration. Dust on the raw gas side impinges on the filter medium, is already retained on the smooth and antiadhesive surface and cannot penetrate into the carrier medium. During the dedusting process in the filtration system, these accumulations are almost completely cleaned away.

Fiberglass fabric offers high temperature resistance and is therefore encountered as a carrier for the ePTFE membrane in many industrial applications. The prerequisite for many years of successful use is a moderate gas composition and low mechanical stress of the fiberglass fabric during operation in addition to a specifically adapted pretreatment of the fabric during manufacture. Under aggressive conditions of use, a carrier medium made of a customized needlona® needle felt can be selected that withstands the chemical and mechanical demands for a longer period that the fiberglass and therefore achieves longer service lives.

Further physical characteristics are a low and stable differential pressure behavior, constant gas volumetric flow, long service lives, low maintenance expenditure and utmost reliability.

BWF Envirotec gives utmost priority to the latest state of the art and ideal characteristics of the individual components in the new PM-Tec® product line. The membrane structure is characterized by optimum orientation and fineness of the fibrils, in addition to a uniform pore size. A low surface tension which reduces the adhesion of fine dusts in addition to a temperature resistance of up to 288 °C ensure optimum filtration properties.

During the production process, BWF Envirotec has perfected the manufacture of filter media, too. Consequently, in-line quality controls and constant air permeability monitoring are performed during the laminating process. The membrane-compatible presentation of the filter media during the entire production process ensures maximum quality. The most demanding emission requirements can be fulfilled by appropriate sewing and sealing technology during the manufacturing process.

The new product line material is available from the roll for manufacturers of filter bags and as made-up filter bags for manufacturers or operators of industrial dedusting plants.

PM-Tec® finds applications in all industrial dedusting plants where very fine dust occurs in the production or manufacturing process. For example, in the cement industry, waste processing plants, power plants, in the chemical and pharmaceutical industry and also in the metal or plastics processing industry. Which filter medium is used for which dedusting process is specifically determined at BWF Envirotec for each customer order. Taking account of the operation-specific characteristics of the filtration system and with emphasis on the most economical solution, the right filter medium for each specific application can be choosen from the wide array of products in the PM-Tec® product line.

The spectrum of BWF´s service in addition to the complete installation of PM-Tec® filter bags include the preventive inspection and maintenance as well as the filter bag investigation.