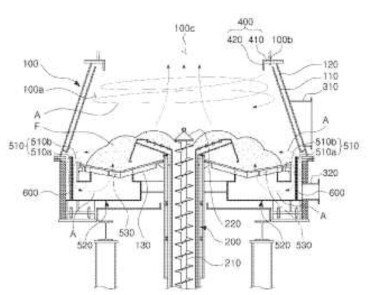

PREPOL Step Combustor (SC) – a simple combustion system for solid alternative fuels

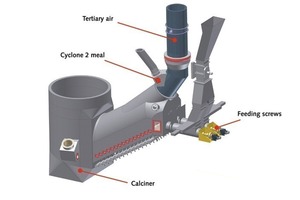

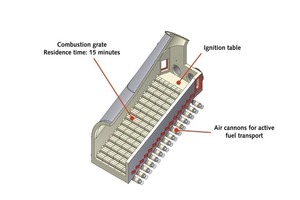

Operational experience shows that waste has to be pre-processed in a mechanical plant before its derived fuel can be used in a cement plant with standard equipment. The fuel must be comminuted to 20-50 mm to entrain into the gas stream and totally burnout within the short retention time in the calciner or at the kiln end. Alternatively, solid waste derived fuel can be treated thermally on a combustion grate which is connected to the preheater system. The article gives a brief introduction into the first installation of the PREPOL Step Combustor (SC) of ThyssenKrupp Industrial Solutions AG in Germany.

1 State of the art of co-processing

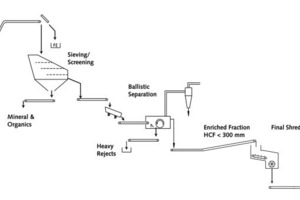

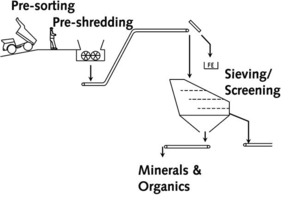

As state of the art industrial and municipal solid wastes must be sorted and shredded for successful co-processing in the cement clinker burning process, as the gas residence time in the system is too short to burn the alternative fuel in its original particle size.

For the combustion in the sintering zone, the waste has to be sorted much deeper, so that only the two-dimensional particles (foils) remain in the product stream and this two-dimensional fraction has to be shredded down to 10-30 mm. For the calciner, the preparation effort is slightly lower. The...