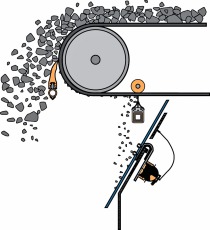

Powerful railcar vibrators deliver high force with low weight

Martin Engineering has introduced a portable vibrator that activates the free flow of bulk materials from closed-top hopper railcars. With one of the highest force to weight ratios available in the marketplace, the Martin IMP3 impacting railcar vibrator delivers the power required to evacuate compacted bulk materials such as Portland cement. Extremely high quality standards for the design deliver superior equipment reliability and long service life, allowing the competitively priced units to improve workplace safety with very little maintenance and a low cost of ownership.

The IMP3 was...