Process for producing cement

(22) 10.10.2013

(43) 19.08.2015

(45) 21.09.2016

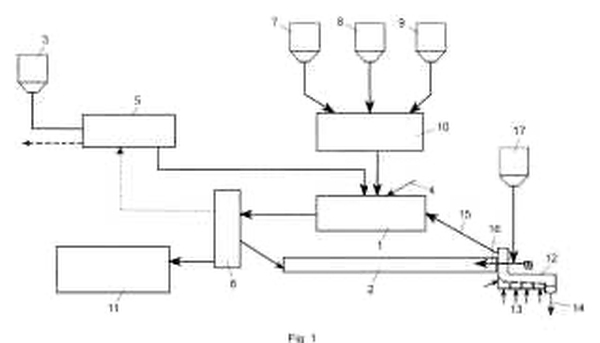

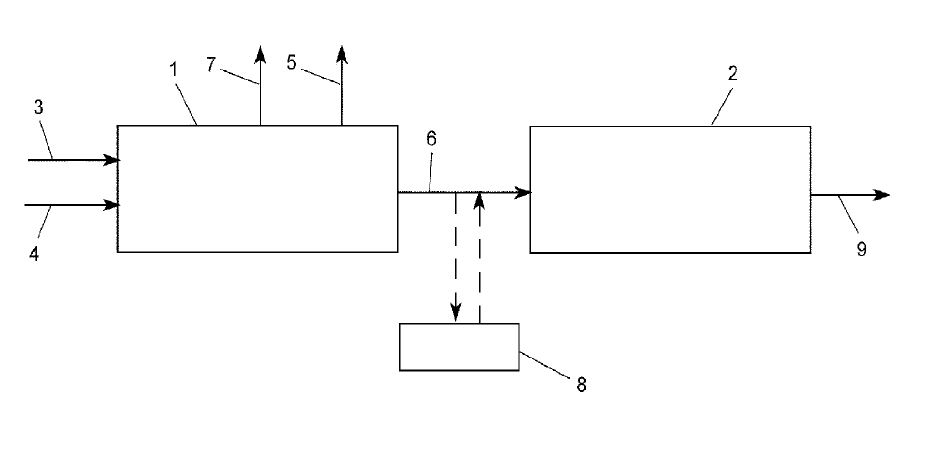

Claims: 1. Process for producing cement by grinding cement clinker and a sulfate source, wherein the sulfate source is gypsum, wherein the cement clinker and the gypsum are ground separately in a high-pressure grinding roller press mill and/or vertical roller mill, characterized in that exclusively the sulfate source is heated in circulation, wherein the sulfate source in the circuit is heated to just below the dissociation temperature thereof to about 100 °C to 120 °C in the circuit and the dissociation temperature of 120 °C to 130 °C is achieved by grinding.

2. Process according to Claim 1, characterized in that the sulfate source is heated by offgases from the thermal line of a plant for producing cement.

3. Process according to Claim 2, characterized in that the sulfate source is heated to a dissociation temperature of the dihydrate to the hemihydrate.

4. Process according to any of Claims 1 to 3, characterized in that after separate grinding the sulfate source is combined with the cement clinker.

5. Process according to any of Claims 1 to 4, characterized in that mill exhaust air from the comminution plant for the sulphate source is discarded.

(73) KHD Humboldt Wedag GmbH, 51067 Köln (DE)

(84) AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR