Product range expansion with high-pressure grinding rolls and equipment in the field of raw material processing

Further to the company’s innovative and reliable equipment for mining, bulk material handling and minerals processing, Takraf is also distinguishing itself as a complete service provider across the entire value chain. For the first time, visitors will be able to have a complete overview of the company's entire service portfolio, which ranges from project development services to technical studies on comminution and minerals processing, innovative fabrication solutions, various technical services and comprehensive after-sales support.

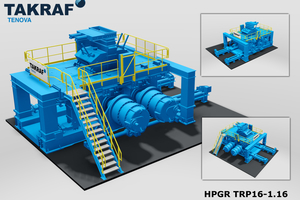

Takraf continues to develop their range of roller presses, with a scale model of a High-Pressure Grinding Roll (HPGR) on display at the booth. Two of these machines are currently being manufactured at the company’s specialized fabrication facility in Lauchhammer/Germany. These machines can each handle more than 1000 tons of cement clinker per hour, with each machine incorporating rolls with a diameter of 1800 mm and a weight of more than 50 t per roller. In order to meet the challenging longevity requirements of such a machine, each roll surface is protected from wear by weld hardfacing for cement applications, and with tungsten carbide inserts for ore processing.

Technical studies, R&D projects and remote support solutions

Technical studies, which compare the techno-economic aspects of different system or equipment layouts are an intrinsic part of every investment process. The quality of the study strongly depends on the experience of the study team and the level of customer involvement. Based upon a common understanding of the weighting of all such decision criteria, the transfer of technical and operational experience and expertise, even beyond the own portfolio, is a key driver in enabling the customer to make a competent decision regarding the optimal solution for the specific conditions of their particular mine. More and more customers appreciate the added value provided by the studies as part of the engineering service portfolio, and for this reason, the company has decided to restructure and tailor their services even better in order to best meet customer requirements.

In order to provide additional benefits and services to the company’s customers based on new digital technologies, several R&D projects in the field of the Industrial Internet of Things (IIoT) have also been advanced. In an attempt to find the most suitable technology which results in the greatest possible benefit for the customer, first pilot machines were equipped with remote data collection and evaluation systems. Utilizing a combination of edge computing and a proprietary azure-based platform established by Tenova, Takraf is able to develop applications that provide valuable insights of the company’s machines through modern and intuitive interfaces across any remote location. Machine design, operation and performance can be optimized in that way. Implementation of more advanced analytics and machine learning strategies are currently on the R&D agenda.

In addition, remote support solutions can also be offered. This enables a remote experts-team to provide on-site assistance to the local commissioning or maintenance personnel using smart glasses and an appropriate software tool.