Quality assurance of crushed limestone intended for use in plaster mix applications

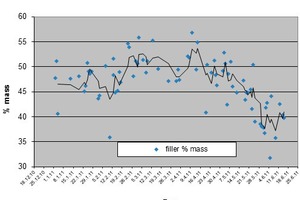

Filler mass fraction is an important property for crushed limestone being used as raw material to produce ready to use plaster. Some approaches for the control of filler mass fraction in the crushed limestone are presented. Special emphasis is placed on the integration of a limestone crushing array in a lime plant as it increases quarry yield and reduces dust emissions from stockpiles by utilizing small size stones not suitable to be fed to the shaft lime kiln hence improving sustainable development and increasing plant revenue.

1 Introduction

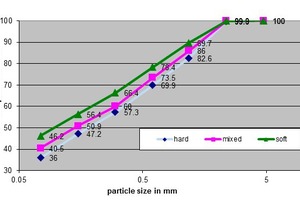

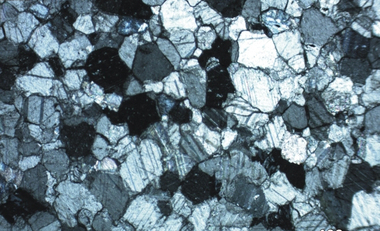

Shfeya lime, located in northern Israel, is a producer of quicklime, hydrated lime and limestone-based aggregates. The raw material being mined in the plant quarry is of two main types: chalk and limestone. The chalk located at the quarry low level is characterized by compression strength of 6-8 MPa and the limestone located at the quarry upper level is characterized by compression strength of 13-14 MPa. The stone absorbs water up to 12-10% by weight respectively (saturated surface dry). Both stone types are of high chemical purity – CaCO3 content is > 99% w/w.

Stone of soft...