Raising the quality of calcium silicate units with simultaneous reduction

of production costs using Statistical

Design of Experiments (DoE)

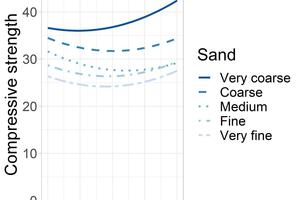

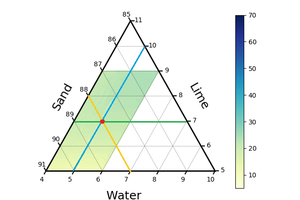

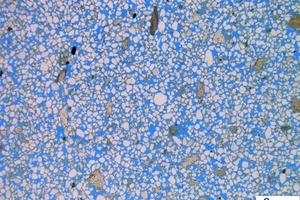

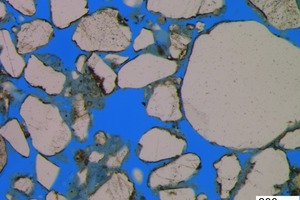

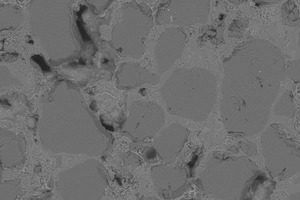

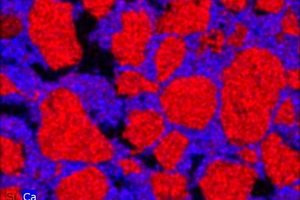

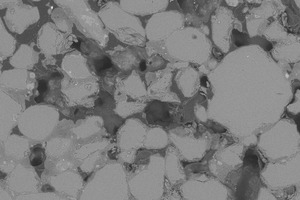

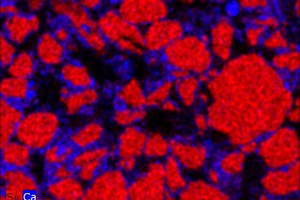

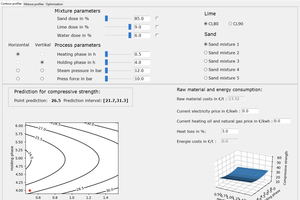

Fundamental investigations were carried out to optimise the production process for calcium silicate units with the aim of saving costs and energy. The statistical design of experiments (DoE) approach was employed because of the large number of possible variations, and a mathematical model was set up. This model can be used to predict the brick compressive strength.

1 Introduction

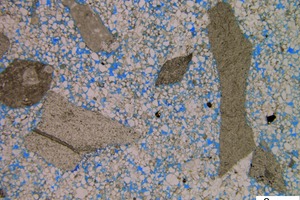

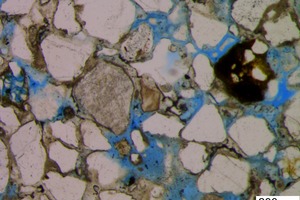

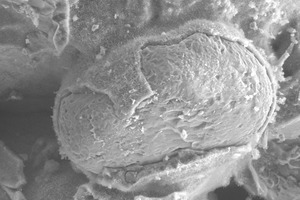

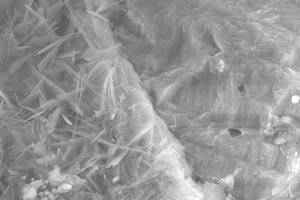

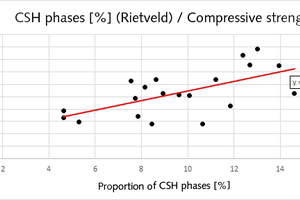

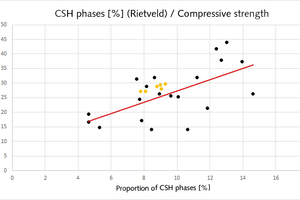

Calcium silicate units are masonry blocks formed from burnt lime and silicate raw materials that are autoclaved in an atmosphere of high-pressure steam at approx. 200°C and 16 bar. The autoclaving process results in the formation of calcium silicate hydrate phases (CSH phases), which are responsible for the necessary compressive strength. The autoclaving process defines the setting reactions of the calcium silicate units and accelerates the formation of the CSH phases [1]. This process is a very energy- and cost-intensive factor for the manufacturing industry. Optimally...

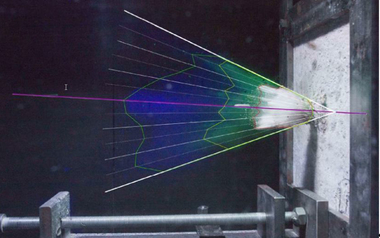

![1 Predicted against observed values of compressive strength [N/mm²]](https://www.zkg.de/imgs/1/5/3/9/6/9/8/tok_0993bc07c092eb519c21e16c38bcca9d/w300_h200_x600_y600_Schade_NEUE_ABBILDUNG_fitplot-8dca9e51373c0de1.jpeg)