Safe confined space entry for chutes, silos and hoppers

An estimated 7% of the U.S. fatalities recorded by MSHA between 1995 and 2011 occurred in a confined space. To reduce that number, conveyor operators are wise to understand exactly how a confined space is defined, and to consider what they can do to prevent serious injuries.

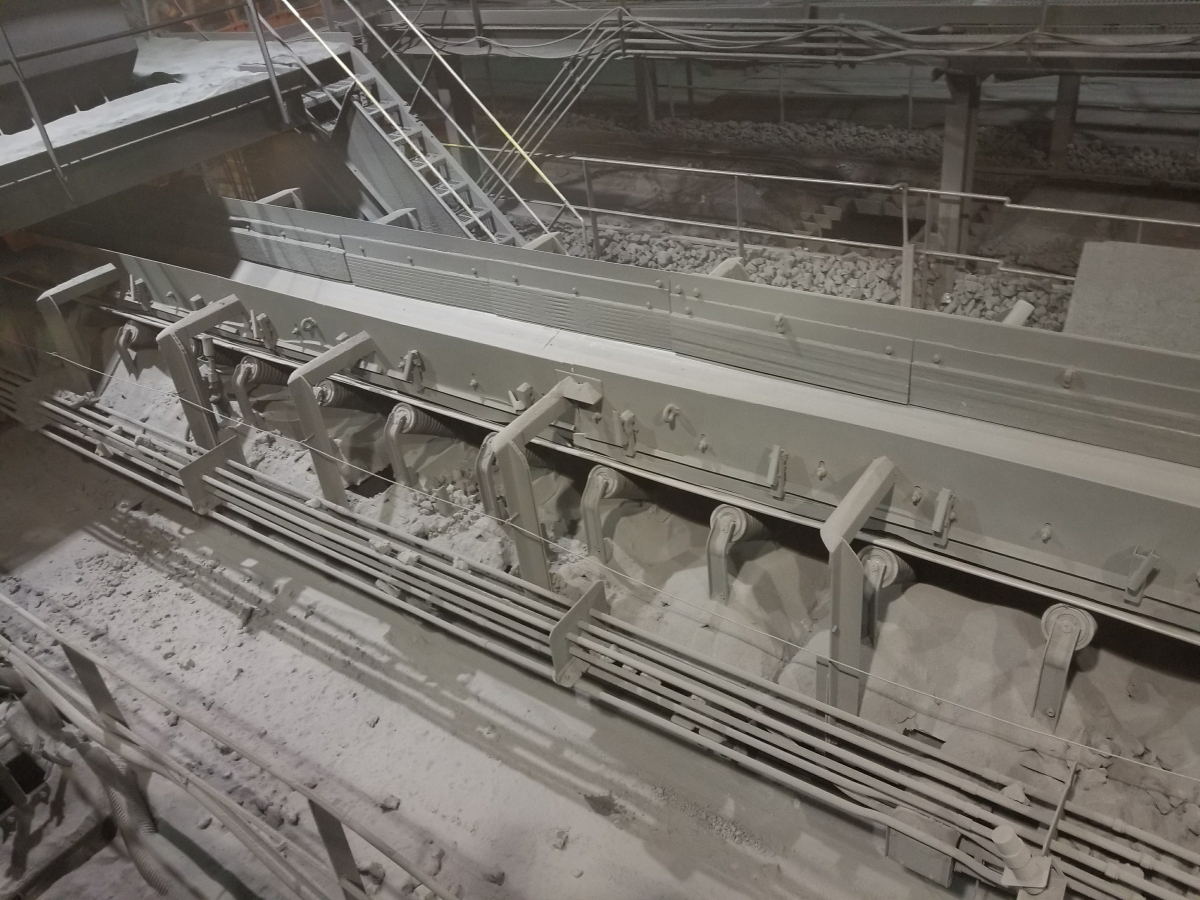

Many factors can cause bulk materials to adhere to the sides of chutes, silos and hoppers – including humidity, moisture content, size/texture of the raw material or increased production volume – resulting in lost capacity or clogging. Ongoing accumulation reduces flow and eventually stops production in order to address the issue, causing expensive downtime and requiring extra labor to clear the obstruction.

“Clearing extensive buildup often involves confined space entry, but the consequences of untrained staff entering a chute, silo or hopper can be disastrous, including physical injury, burial and asphyxiation,” said Product Engineer Daniel Marshall. “Without proper testing, ventilation and safety measures, entering vessels containing combustible dust could even result in a deadly explosion.”

What is confined space entry?

The Occupational Safety and Health Administration (OSHA) defines “confined space” as an area not designed for continuous employee occupancy and large enough for an employee to enter and perform assigned work, but with limited or restricted means for entry or exit [1]. “Permit-required confined space” means a confined space that has one or more of the following characteristics:

(1) The vessel contains or has the potential of containing a hazardous atmosphere such as exposure to explosive dust, flammable gas, vapor, or mist in excess of 10% of its lower flammable limit (LFL). Atmospheric oxygen concentration below 19.5% or above 23.5%

(2) There is the potential for material to engulf, entrap or asphyxiate an entrant by inwardly converging walls or by a door which slopes downward and tapers to a smaller cross-section; or

(3) Contains any other recognized serious safety or health hazards

Entering a confined space

Working in confined spaces typically requires:

Special personnel training

Safety harness and rigging

Extensive preparation

Added personnel for a ‘buddy system’

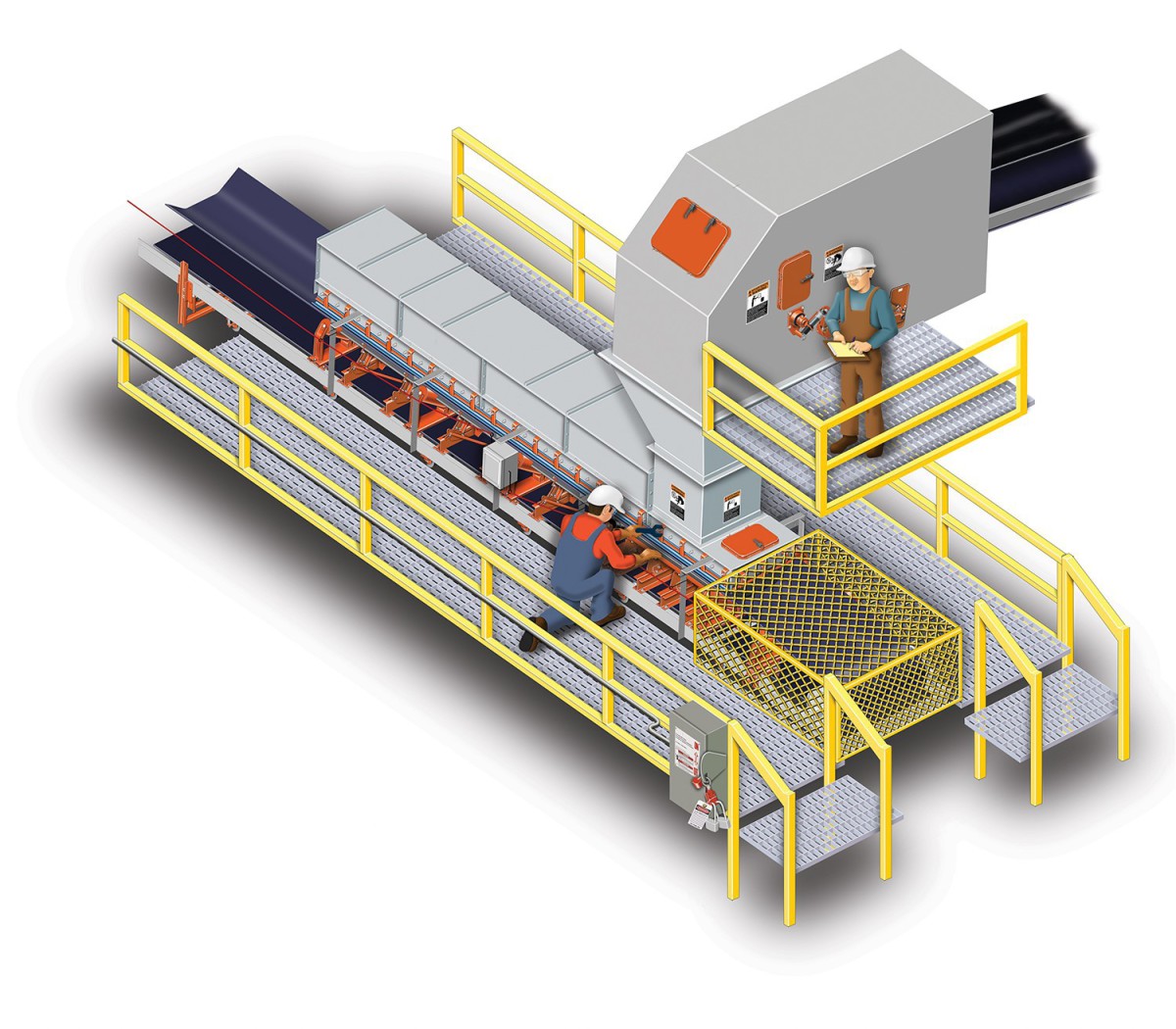

“Systems designed to minimize permit-required confined spaces can provide a significant return on investment, and the best time to reduce the amount of confined-space entry for component maintenance and replacement is during the specification and design stages of a project,” Marshall continued. Many manufacturers offer systems and products that can reduce the need for confined space entry. Examples would include:

Modular chute designs with abrasion-resistant liners

Chutes that hinge open and lay down for liner replacement

Skirtboards with external liners

Belt cleaners that can be serviced without confined space entry

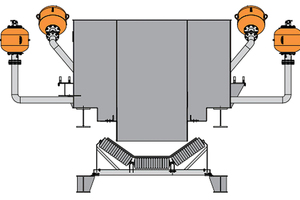

Flow aids such as air cannons and vibrators to reduce buildup

Modular air cleaners for specific locations rather than centralized dust collection

Global regulations, standards and best practices

Rules regarding confined space entry vary greatly depending on the country, even down to the state, province or prefecture level. As always, regional and local codes should be identified and followed, but general rules can be drawn from regulations established in major industrial markets such as Australia, New Zealand, Canada and the United States [2]. Commonalities between governmental regulations provide employers with a measured approach to safety. These procedures include:

Prior to starting the job

Review the permit and the job-specific

work procedures

Gather and inspect all necessary PPE

Test and/or calibrate any safety gear,

test instrumentation or communication tools

If a current Job Safety Analysis (JSA) or

safety check list does not exist, perform a risk

assessment

Hold a pre-job meeting making sure all workers are aware of the hazards and safe work practices

Conduct proper tests for toxins, vapor, dust levels, oxygen levels and material-specific hazards

Perform as much cleaning and maintenance as possible outside of the vessel.

Post completed confined space entry

permit outside of the vessel

Isolate contaminants and moving parts to prevent the accidental introduction of materials

Proper lock-out/tag-out/block-out/test-out procedures must be completed and documented prior to entry

During procedure

Perform maintenance/cleaning using non-toxic substances such as water and avoid using heat/fire in the confined space. Never use oxygen to purge a confined space, as this can create a fire and explosion hazard

Provide ventilation if possible

Select personal protective/safety equipment such as safety helmet, gloves, hearing protectors, safety harness and lifeline and breathing apparatus

Assign a trained observer to monitor the procedure and internal conditions, and provide escape assistance if needed

Practice fast evacuation of the confined space

Closing thoughts: covering your access

“Over time, well-designed access improves safety and saves money,” Marshall added. “Safe access that is carefully located and adequately sized will increase dependability and also reduce the downtime and associated labor required for maintenance.” He advises that companies consider equipment designs which minimize the need for confined space entry, including improved access doors, vibrators, air cannons or silo cleaning services. “Conveyor systems that are properly outfitted with appropriate cleaning and material discharge equipment create a safer workplace, while experiencing longer life and less downtime,” he concluded.

//www.martin-eng.com" target="_blank" >www.martin-eng.com:www.martin-eng.com