Significant improvement of environmental footprint of paper sacks

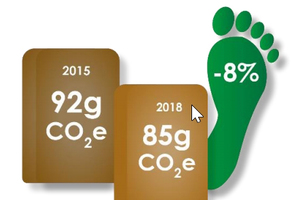

The European kraft paper and paper sack industry has put further efforts into improving its carbon footprint. In only three years, between 2015 and 2018, the carbon intensity of a single paper sack was reduced by 8%. This is concluded by the latest carbon footprint analysis on European paper sacks conducted by the Swedish research institute RISE on behalf of the European Paper Sack Research Group (ESG), a collaboration between Eurosac and Cepi Eurokraft. An infographic presents the most important results. The recently published report by RISE on the fossil carbon footprint of average European paper sacks summarises an impressive achievement: in this three-year period, the industry improved its emissions during the subsequent stages of production from cradle to the factory gate by 8%, from 92 g CO2e to 85 g CO2e. Part of the explanation for this is lightweighting effects based on an improved paper quality and a reduction of the share of other materials such as plastic films in the paper sack. Per tonne of sack kraft paper the fossil carbon impact decreased by 0.5% from 458 kg CO2e in 2015 to 455 kg CO2e in 2018. The emissions arising during kraft paper production account for 66% of the total carbon footprint for each individual paper sack.

Target of EU action plan exceeded

When looking at the data for a longer period, there is a consistent downward trend in the cradle-to-gate fossil carbon impact of average European sack kraft paper and paper sacks. It even exceeds the targets set by the EU climate action plan of reducing the greenhouse gas emission by 20% between 1990 and 2020. In only 11 years (from 2007 to 2018), the fossil carbon impact per tonne of sack kraft paper has been lowered by 20% (from 570 kg CO2e to 455 kg CO2e). With 28% improvement (from 118 g CO2e to 85 g CO2e), the result for paper sacks is even more significant. The efforts of the European kraft paper and paper sack industry to continuously improve its environmental imprint will be just as high in the upcoming years. “With a reduction of the emissions by 40% to even 55%, the European Union has set an ambitious target for 2030,” says Catherine Plitzko-Kerninon, General Delegate, Eurosac. “Paper sacks are a low carbon, circular and bio-based packaging solution – this is a good starting point for our industry to contribute to its achievement.”

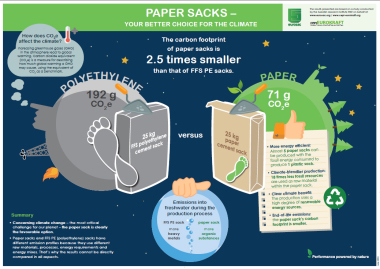

Climate-friendly and efficient production

One key factor is a climate-friendly production: already today, the production of sack kraft paper is, to a high degree, energy self-sufficient: 77% of all energy needs (heat and electricity) is generated on-site. Adding to that, the production uses a high degree of renewable energy sources: 89% of the fuels are renewable and used to generate heat, steam and electricity. Most of them, that is 81%, are produced as side streams of the pulp and papermaking process.

Positive climate impact with extended system boundaries

When extending the analysis to include biogenic greenhouse gas emissions and removals in the calculation, paper sacks would already be climate-positive packaging solutions today. Biogenic emissions arise from the combustion or degradation of biofuels and bio-based products. The removals refer to the carbon sequestration that is associated with forest management, the production of biofuels and of bio-based non-fibre inputs. In 2018, the cradle-to-gate biogenic carbon footprint accounts for -120 g CO2e per paper sack. In combination with the cradle-to-gate fossil carbon footprint of 85 g CO2e per sack, the result would even be at -35 g CO2e per paper sack which has a positive impact on the climate. The key data of the study is summarised in an infographic. A fact sheet gives further background information on the analysis. All documents are available for download on the websites: