The next generation in cooling

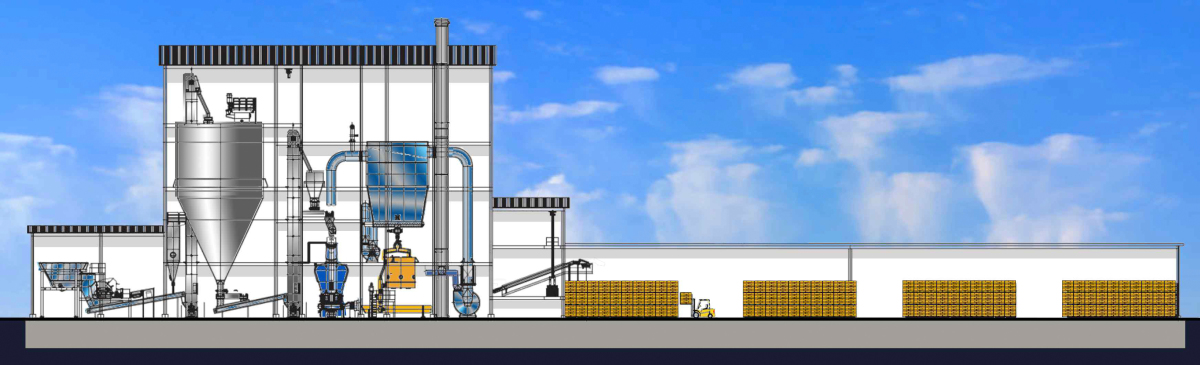

After successfully supplying the gypsum calcining industry with Rotary Drum Coolers for more than two decades, Claudius Peters has developed the next generation of Rotary Drum Coolers with many new features that optimize the gypsum calcining process and decrease the need for maintenance.

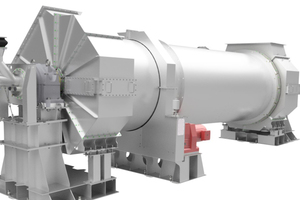

The Rotary Drum Cooler

Materials at processing temperatures of approx. 150 ºC must be cooled to lower temperatures for further processing. Claudius Peters offers a choice of fast and efficient cooling solutions, based on proven technology.

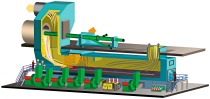

The Claudius Peters Rotary Drum Cooler can yield up to 100 t of product per hour. It works on the counter-current indirect principle, with an air fan drawing cooling air through a tube bundle and transferring the heat energy from the stucco into the air.

The heat energy of the cooling air in this process can be re-used as pre-heated combustion air for the hot gas generator, providing a considerable reduction in plant energy costs. Material to be cooled is homogenized during the cooling process. The retention time this allows effective reduction of unwanted by-products such as soluble anhydrite and dehydrate.

//www.claudiuspeters.com" target="_blank" >www.claudiuspeters.com:www.claudiuspeters.com