The thermal history of granulated blast furnace slag and its impact on reactivity

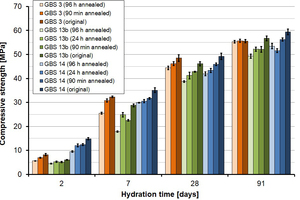

Many approaches have been developed to evaluate the reactivity of GBS in cementitious systems based on glass content, chemical composition, fineness, etc. However, a general method could not be found. The basic idea of a research project was to use already established analytical techniques. With Differential Scanning Calorimetry and viscosity measurement, in combination with classical cement-based tests, a correlation between the thermal history of GBS and its reactivity in a blastfurnace cement could be demonstrated for the first time.

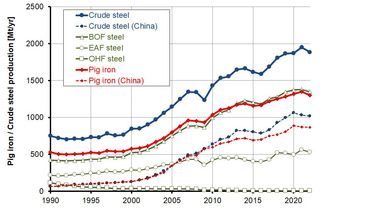

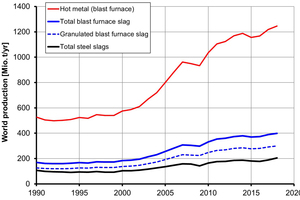

About 400 million t of blast furnace slag are produced annualy world-wide, together with about 1247 million t of hot metal (2018). About 300 million t are quenched forming the glassy granulated blast furnace slag (GBS). For more than 130 years the GBS has been used as a clinker substitute in cement and concrete due its latent hydraulic property. Many approaches were developed in order to evaluate GBS reactivity in cementitious systems based on glass content, chemical composition, fineness, etc. However, a general method could not be found. Only a rough differentiation might be possible....

![3 Parameters with influence on the properties of granulated blast furnace slag [2]](https://www.zkg.de/imgs/1/5/5/0/2/0/5/tok_e7454c1aa817bc9b88ce10f63e04b1d2/w300_h200_x600_y425_Materials_Ehrenberg_Thermal_history_Figure_3_Parameters-29a9a0154df082bf.jpeg)

![10 Temperature dependence of viscosity of GBS 3. Line is best fit through the data using MYEGA viscosity model [9]](https://www.zkg.de/imgs/1/5/5/0/2/0/5/tok_ed60b11483f0a16dfa011b0592293d56/w300_h200_x177_y181_Materials_Ehrenberg_Thermal_history_Figure_10__Viscosity_GBS_3_-d73cd357d5225176.jpeg)