Calectra’s thermal battery delivers cheaper and cleaner process heat for cement and lime producers

Calectra’s power-to-heat thermal storage technology can significantly reduce process heating OPEX (33% in Germany in 2024) and combustion-related emissions (up to 100% depending on power source) for cement and lime manufacturers. It is leveraging the growing trend of low-cost, off-peak electricity availability resulting from the surge of renewables. Over 93% of newly built energy capacity is renewable. Calectra thermal storage converts low-cost electricity into high-temperature heat, stores that heat in its patent-pending ceramic bricks, and delivers heat from these bricks to industrial processes on-demand at temperatures up to 1600 ºC, achieving over 90% round-trip efficiency.

1 Process heating - a major source of costs and CO2 emissions

The heat required for the production of cement and lime is very expensive, making up 20-25% of production costs in cement [1] and 30% in lime [2]. Heating in these production processes has not changed significantly in decades or longer, and major upgrades to these processes, with accompanying savings in energy costs, could completely reconfigure the cost to produce these materials.

The production of cement and lime is also emissions- and energy-intensive. The production of 1 t of cement emits 0.9 t of CO₂ and requires 1.1 MWh of energy [3]. Similarly, the production of 1 t of lime generates on average 1.2 t of CO₂ and requires 1.8 MWh of energy [4]. The cement and lime industries are significant contributors to the world’s CO2 emissions, accounting for 8% and 1% of global CO2 emissions, respectively [3].

Both cement and lime rely on the decomposition of limestone (CaCO₃ CaO + CO₂) in their processes, and this is responsible for these CO2 emissions in two main ways. 60% of these emissions are process emissions and take place as CO2 is released as part of the chemical process of limestone decomposition. The remaining 40% of emissions are combustion-related [3,4]. The decomposition (calcination) of limestone requires high-temperature heat, at 900-1000 °C. It is noteworthy to mention that cement manufacturing requires even higher temperatures due to the clinkerization step. The heat required in both of these production processes is usually generated by burning fossil fuels such as coal, petroleum coke, or natural gas, which is why combustion-related emissions are so prevalent in the production of cement and lime.

2 The economic impact of CO2 on the cement and lime industries

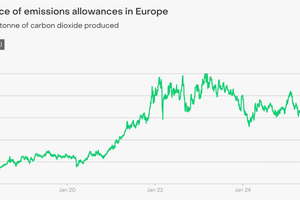

Cement and lime producers manufacturing in regions with a carbon price, such as the EU (Emissions Trading System, ETS) and California (Cap-and-Trade-System), are under a growing financial pressure to cut their CO2 emissions. With the current EU ETS price of € 75/ t of CO2, the additional cost is € 90/ t and € 67.50/ t for lime and cement, respectively. Figure 1 shows the development of the emissions allowance price in the ETS between 2018 and 2025 [5].

Going into effect in 2026, the EU’s Carbon Border Adjustment Mechanism (CBAM) imposes a carbon price on imports of carbon-intensive goods, including cement and lime, to align with the EU ETS and prevent carbon leakage [6]. Hence, companies exporting cement and lime to the EU will also be impacted. Solutions for reducing emissions in cement and lime production will become more important than ever before in regions implementing these policies as well as in companies exporting to these regions.

3 The growing opportunity of low-cost, off-peak electricity

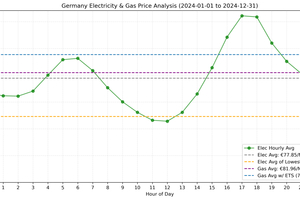

The world has entered a new era in electricity markets, where electricity prices fluctuate more frequently and low-cost, off-peak electricity is available on a regular basis [7]. Figure 2 shows Calectra’s analysis of hourly wholesale electricity price fluctuations in Germany for 2024 and compares that with the average wholesale electricity price and natural gas cost for industrial users with and without the carbon allowance price imposed by the EU Emissions Trading System. This analysis shows a clear potential for meaningful energy cost reductions if one can take advantage of electricity price fluctuations, with a 37% reduction in energy costs in this analysis when comparing natural gas to the 4 lowest-cost hours of electricity per day. We have performed a similar analysis for most of Europe and North America, and these trends apply consistently in a wide range of regions.

The growing trends of fluctuating electricity prices and the availability of low-cost electricity are due to the fact that renewables account for 93% of global power additions, with solar energy contributing two-thirds [10]. Solar and wind are deployed at scale worldwide because they are the cheapest ways of generating power [11]. This economic opportunity keeps on widening. The International Energy Agency finds that 5000 GW of new renewable energy capacity will be added between 2024 and 2030 [12]. With this overwhelming trend toward a new, lower-cost energy source, it is inevitable that this electricity will be used for the widespread production of industrial process heat.

4 Calectra - technology for cheaper and cleaner industrial heat

Calectra’s power-to-heat thermal storage technology leverages this growing opportunity in electricity markets, enabling cheaper and cleaner process heating up to 1600 °C for the cement and lime industries.

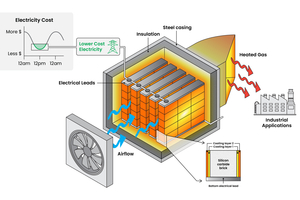

Calectra converts 4-8 h/d of low-cost, off-peak electricity into high-temperature heat, stores that heat in its patent-pending bricks at up to 1800 ºC for long durations, and delivers heat from these bricks to industrial processes on-demand at temperatures up to 1600 ºC, achieving over 90% round-trip efficiency. The heat is extracted by blowing air, flue gas, or another suitable heat transfer gas through the array of bricks and then piping the hot gas into the industrial process. The technology can be installed as a retrofit, maximizing the value of existing production lines. Figure 3 demonstrates this process of using intermittent electricity to generate and store high-temperature heat that can be used to produce cement or lime.

Calectra’s thermal storage technology revolves around its brick material, which has been specifically designed for high-temperature, safe, and scalable heat delivery. First, the 2-in-1 heater and storage technology uses the same brick to both convert electricity into heat and store that heat. The heat generation is done via volumetric resistive heating by passing the electric current through the electrically conductive brick. Second, it only uses non-toxic, non-combustible materials in the system, ensuring maximum safety. Finally, Calectra uses a widely used refractory material as the core component in its bricks, relying on robust global supply chains and production methods.

The technology is currently being tested at Calectra’s HQ in Oakland/California, near San Francisco. The technology is also being analyzed at the Lawrence Berkeley National Laboratory to ensure reliable system performance.

Calectra aims to conduct its first MWh-scale customer pilot next year and is seeking mission-driven partners for this initiative.