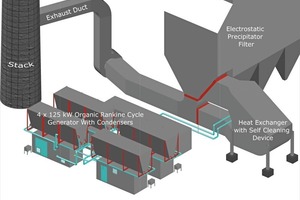

A new waste heat to power project, on target for completion this September, will see Heatcatcher Ltd, a technology integration company based at the Sussex Innovation Centre, install their innovative Heatcatcher System at the Thrislington Lime plant near Durham. Heatcatcher, founded by Darren Bryant three years ago, have built up a successful waste heat to power company with the support of its technology and academic partner the University of Brighton, under a two year Knowledge Transfer Partnership programme to develop its unique waste heat to power forecasting model. Lime and cement manufacture is currently one of the most energy intensive and greenhouse gas producing industrial processes in existence. The Heatcatcher System will help Steetley Dolomite Ltd – a world leader in lime production – to recover 4 MW of low temperature waste heat from the rotary kiln exhaust and convert it to 0.5 MW of low carbon cheaper electrical power. The technology at the heart of the Heatcatcher System is 4 x 125 kW Organic Rankine Cycle Generators. The ORC uses the waste heat to vaporise a refrigerant, which in turn drives a micro turbine generator. The variable frequency and voltage output of the generator are converted to match the grid, and this electrical output is fed back into the plant’s power supply, providing enough low carbon electricity to reduce the amount of electricity required to run the lime kiln by 2966 MWh per year and reducing the site’s CO2 emissions by 1610 t.

John Carlill, Managing Director of Steetley Dolomite, said “The Heatcatcher system allows us to make a significant step forward in the change to the electrical efficiency of our plant at Thrislington. The integration of proven ORC technology to the exhaust of our dolomitic lime kiln enables us to produce our own on site carbon free electricity from the kiln exhaust. In addition to using the waste heat as free fuel, we also co-fire our kilns with biomass to minimise our impact on the environment. The project offers an attractive return on investment, when considering the 1.3 million £ investment against purchasing 3000 MWh per year of electricity from the grid over the next 10 to 15 years”.

Darren Bryant, CEO of Heatcatcher Ltd, said: “It’s a great feeling to be installing our first system with Steetley Dolomite, but this is only the beginning. We expect that in the next 5–10 years, all lime and cement kilns will feature a Heatcatcher. As more companies want to make savings in their processes, and with a growing responsibility to reduce greenhouse gas emissions, our system will prove to be the ideal solution for this industry.”