Cement raw material grinding equipment

(22) 13.12.2024

(43) 14.01.2025

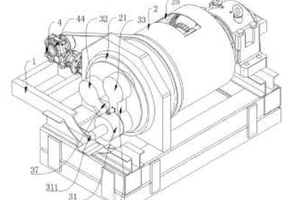

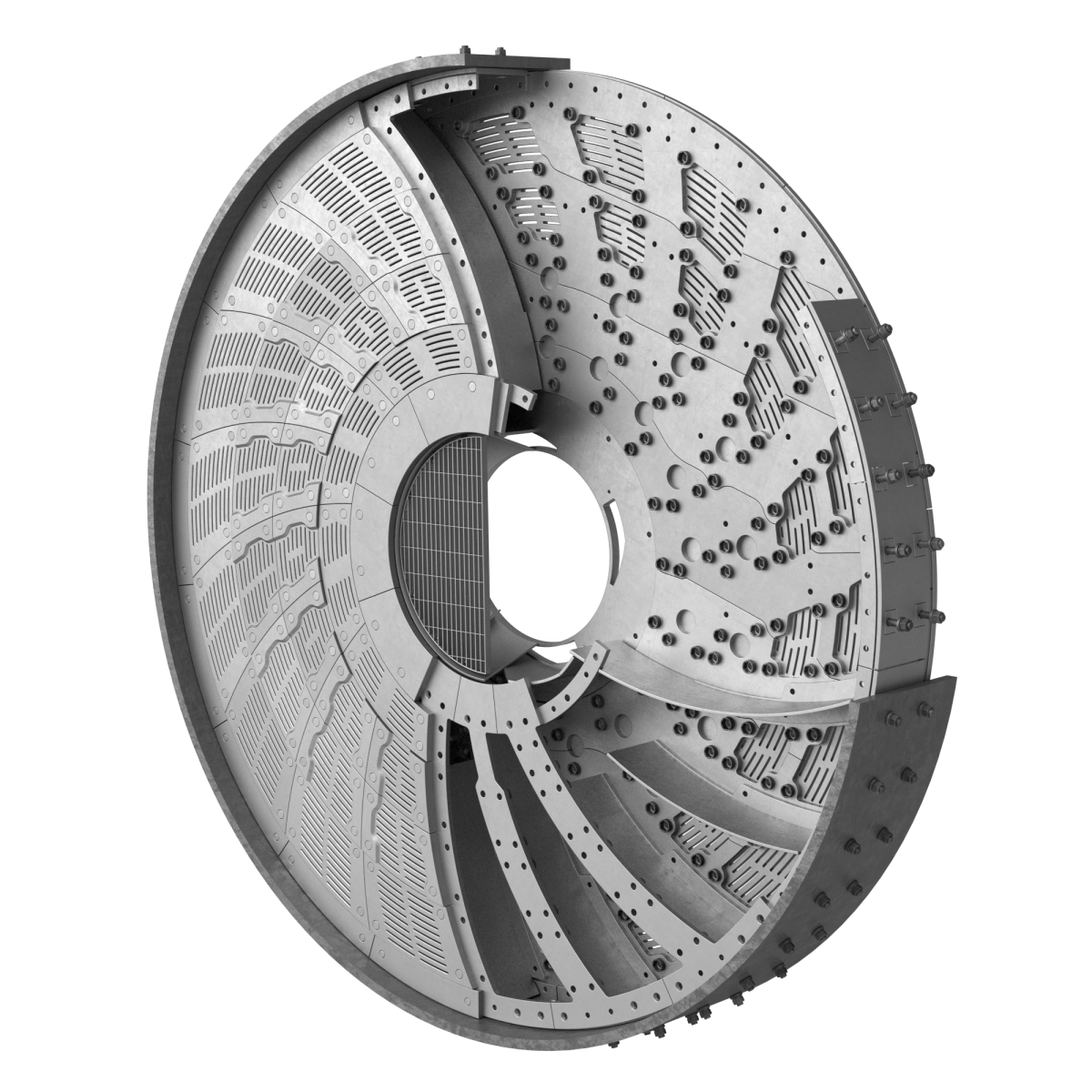

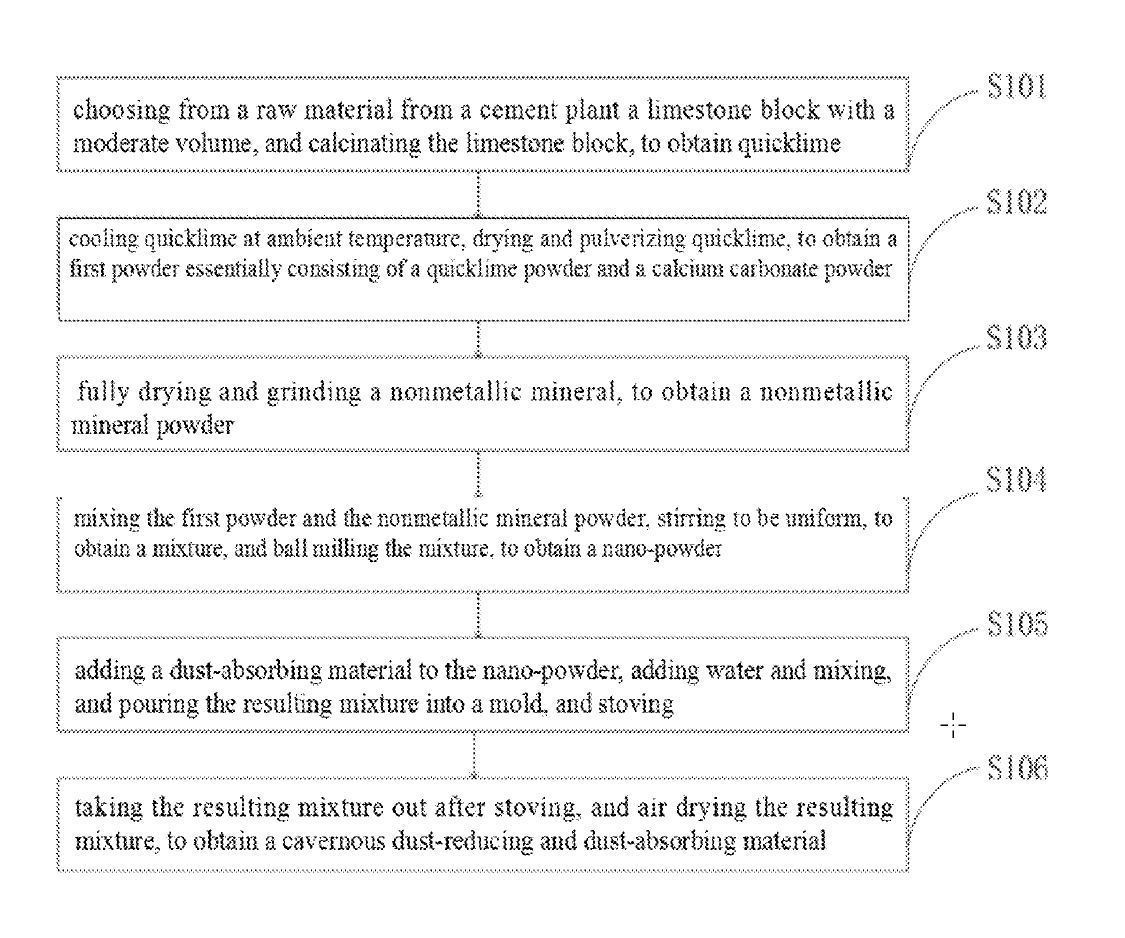

(57) The invention provides cement raw material grinding equipment, which belongs to the technical field of grinding, and comprises a support plate, a first ballmilling cylinder, a second ball-milling cylinder, a third ball-milling cylinder, steel balls, a screening mechanism and a rotating mechanism, the supporting plate is rotationally arranged at one end of the containing cylinder, the first ball milling cylinder, the second ball milling cylinder and the third ball milling cylinder are distributed in the containing cylinder in a triangular shape and rotationally connected with the supporting plate, and through holes are formed in the first ball milling cylinder, the second ball milling cylinder and the third ball milling cylinder. The plurality of steel balls are divided into three specifications of minimum, medium and maximum according to the diameters and are sequentially arranged in the first ballmilling barrel, the second ball-milling barrel and the third ball-milling barrel; the screening mechanism is used for screening the raw materials and correspondingly inputting the raw materials with small, medium and large diameters into the first ballmilling cylinder, the second ball-milling cylinder and the third ball-milling cylinder; and the rotating mechanism is used for driving the first ball-milling cylinder, the second ballmilling cylinder and the third ball-milling cylinder to revolve around the center of the supporting plate and rotate around the axes of the ball-milling cylinders. The cement raw material ball-milling device can improve the ball-milling efficiency and effect of cement raw materials.

(71) Xinxiang Pingyuan Tongli Cement Co. Ltd.; Henan Tongli Cement Co. Ltd., (CN)