Ceremonial inauguration of the world’s first building made of carbon reinforced concrete Cube

Since the early 1990s, TU Dresden (TUD) has been researching on the technology of carbon reinforced concrete. Since 2014, the research has been made in the framework of the large-scale research project of C³. At the end of September 2022, the world‘s first building made of carbon reinforced concrete, the so-called Cube, was officially inaugurated in Dresden/Germany.

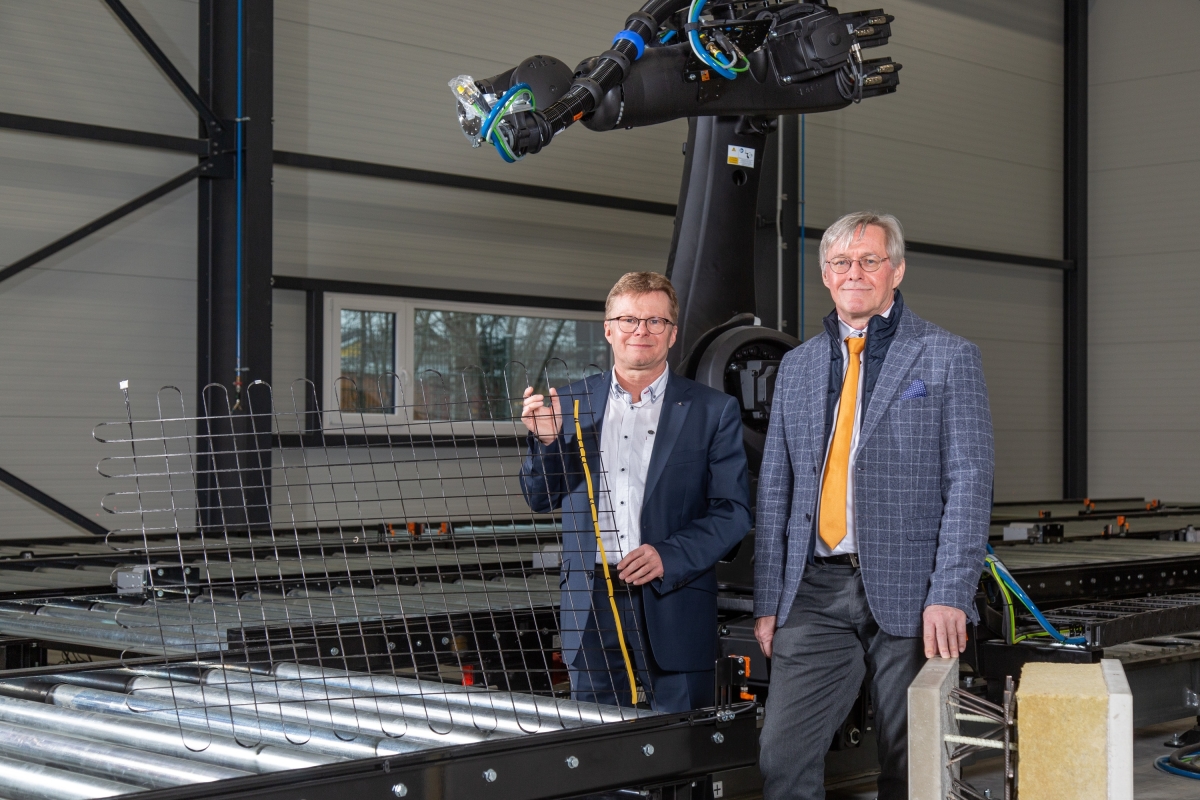

The Rector of the Technische Universität Dresden, Ursula M. Staudinger, and the building owner and Director of the Institute of Concrete Structures, Manfred Curbach, together with the Minister of State, Thomas Schmidt (Saxon State Ministry for Regional Development), the State Secretary, Thomas Kralinski (Saxon State Ministry for Economics, Labour and Transport), the Ministerial Councillor in the Innovation Promotion and Structural Strengthening Department of the Federal Ministry of Education and Research, Hans-Peter Hiepe, and the Mayor of Education of the City of Dresden, Jan Donhauser, heralded a new building era. With the completion of the Cube, important building blocks were laid for future construction projects in the new building sector.

“The carbon concrete building Cube is a big step towards a future-proof building sector. Carbon concrete can already drastically reduce the energy consumption of the construction industry. Used on a large scale, it can make construction more energy-efficient, more material-friendly and more circular. At the same time, the new building material can be used to build in a technically and aesthetically very sophisticated way. This is a great opportunity for climate-friendly building. I am sure that the carbon reinforced concrete construction method developed and established in Saxony will give a great boost not only to building construction, but also to road and bridge construction,” emphasised Minister Schmidt at the inauguration.

For the Mayor of Education, Jan Donhauser, it is no coincidence that the world’s first house made of carbon concrete is located in Dresden: “With the Cube, the state capital Dresden continues to write architectural history. Solutions like this are urgently needed to conserve resources. That is why we are also planning to build two school sports halls with carbon concrete. Dresden can score points with its core competence, the close cooperation between administration, science and business.”

In the area of research and development, Saxon companies and institutions in particular – AIB – Architekten Ingenieure Bautzen GmbH, Assmann Beraten und Planen Niederlassung Dresden, Betonwerk Oschatz GmbH, Institute of Concrete Structures at Technische Universität Dresden, Institute of Concrete Structures at HWTK Leipzig, as well as texton e.V. as an associated partner – have contributed significantly to the success. “Today is a great day for carbon concrete and for the entire Free State of Saxony. Because with the Cube, an innovation ‚Made in Saxony‘ becomes visible and walkable. Many thanks to all those who have contributed to the success of this building with a great vision and a lot of heart and soul. The Saxon State Ministry of Economic Affairs, Labour and Transport will continue to support innovations in the future in a way that is open to all sectors and technologies. Particularly in view of the required sustainability, I hope that carbon concrete will be used worldwide in the future”, said Thomas Kralinski, State Secretary for Economic Affairs and Labour.

The best possible partners were found for the innovative building through a multi-stage award procedure. The requirement was to realise this building economically and at the same time to enable an innovative technology. Hans-Peter Hiepe is therefore certain: “The Cube stands for an innovation policy that makes radically new thinking and building possible.” With a joint venture consisting of Hentschke Bau GmbH and Bendl HTS Sebnitz, it was possible to combine forces and existing know-how to break new ground in construction with carbon concrete. Instead of steel reinforcement, carbon mats from solidian GmbH, Wilhelm Kneitz Solutions in Textile GmbH and carbon rods from thyssenkrupp Carbon Components GmbH (now Action Composites) and SGL Carbon as well as glass from Schöck Bauteile GmbH provide the stability of the material. A special mix was also used for the concrete: a high-performance concrete developed for Cube by Pagel Spezial Beton GmbH. The concept design came from the architectural office Henn, and AIB – Architekten Ingenieure Bautzen GmbH was responsible for the general planning. Carbon concrete is a combination of high-performance concrete and carbon fibres, which are processed into a scrim or a bar and serve as reinforcement. The very low use of concrete and the considerable reduction of CO2 emissions compared to traditional reinforced concrete construction make carbon concrete an interesting building material – also from aspects of sustainability and the environment. “Climate-friendly construction is a central research topic at Technische Universität Dresden as well as worldwide, which will become even more important in the future. With the Cube on the campus of Technische Universität Dresden, we see an excellent example of how research results find their way into practice”, emphasised Rector Ursula M. Staudinger.

Thanks to funding from the Federal Ministry of Education and Research, up to 226 companies, institutions and associations have been working since 2014 on the successful introduction of carbon concrete to the market in an interdisciplinary manner and under the umbrella of C³ – Carbon Concrete Composite e.V.