Effects of sodium butyrate and hydroxyl silicone oil on the grinding performance of the cement grinding aid

Cement grinding aids can increase the output of cement production, reduce the power consumption.

In this paper, sodium butyrate and hydroxyl silicone modified cement grinding aids (MG) was studied,

compared to the conventional cement grinding aids (CG). The cement samples with CG/MG

were characterized by lab ball mill and industrial experiment. The result showed that, hydroxyl silicone

can improve the surface tension of ethanolamine, the addition of sodium butyrate can improve

the dispersion of cement particles, corresponding to the repose angle data.

The cement sample with the MG had higher Blaine, smaller particle size, and bigger repose angle, the 3~32μm content of cement was increased. In the industrial experiment, the MG increased

the output by 15t/h, and decreased the power consumption by 1.7kW·h/t.

1 Introduction

With the requirement of the energy consumption decrease and the environment protection, the cement industry has a difficult task of energy saving and carbon reduction. The traditional mill technical reform can effectively improve the cement grinding condition then reduce the consumption. However, the cost is very high, which brings a great economic burden to a cement company. The cement grinding aids are added when the cement is ground, which can reduce the particles surface energy, eliminate the static electricity, reduce the effect of agglomeration, improve the cement grinding production and reduce the power consumption [1-3].

Since the beginning of the 21st century, cement grinding aids have been widely used in China. The traditional formula of cement grinding aids, mostly composed of glycerol, triethanolamine, iso-propanolamine organic compounds [4-6], generally improve the cement grinding production by 10~15% and reduce the power consumption by about 2 kW · h/t. Recently, the development of cement grinding aids is limited, the formula and the performance are seriously homogenized. More attention is put on improving the strength of cement, and less people study improving the workability of the cement mill system. Cement grinding aids need a new breakthrough to meet the higher requirement under the new stage.

In common cement grinding aids, alkanol plays the main role, added to the cement material during cement grinding, the use of its hydroxyl group, through hydrogen bonding adsorption on the surface of the material particles, reducing the surface energy of the powder particles, at the same time, the lone pair electrons of the nitrogen atom of alkanol amine mutually repel each other, avoiding the adsorption between cement particles, then improving the efficiency of cement grinding. Based on this theory, selecting the appropriate chemical compound to reduce the surface tension of the cement grinding aid, and improve the dispersion of cement particles, can effectively improve the performance of the cement grinding aid.

In this paper, sodium butyrate and hydroxyl silicone modified cement grinding aids were studied, the components were optimized to improve the dispersion of cement powder. The cement grinding aids performance was improved with the same content of ethanolamine. Meanwhile, the thinning of the cement particle also promoted the hydration process then improved the cement strength [7-10]. The result was verified by lab ball mill and industry experiment, which provide the direction for the research of cement grinding aids.

2. Experiment and materials

2.1 Materials

The DEIPA was from the Lucky Stone Chemical Company Ltd./China, 81% content, the sodium butyrate and the hydroxyl silicone oil were from the Xi Long Scientific Company Ltd, AR. The cement raw materials were from China Resource Cement Company Ltd in Nanning/China. The cement compounds were shown in Table 1:

2.2 Methods

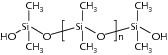

The hydroxyl silicone oil was added to 30% DEIPA with 0%, 3%, 5%, 7% then mixed with the remaining content of water. The surface tension was tested using a DCAT 25 surface tension meter. The effect of the different content of hydroxyl silicone oil on the cement grinding aid was measured by the platinum plate method.

To test the effect of the sodium butyrate, 0%, 3%, 5%, 7%, 10% sodium butyrate were added to 30% DEIPA and the rest was water, each one of the mixtures were added to 5 kg of cement raw materials with the dosage of 0.05%, then ground with the same times. The cement sample was added into a funnel of certain height, then dropped slowly on a round disc to form a cone till the height of the cone remains unchanged. The repose angle was calculated with the following formula:

⇥(1)

Where A was the repose angle, h was the height of the cement cone, r was the radius of the round disc.

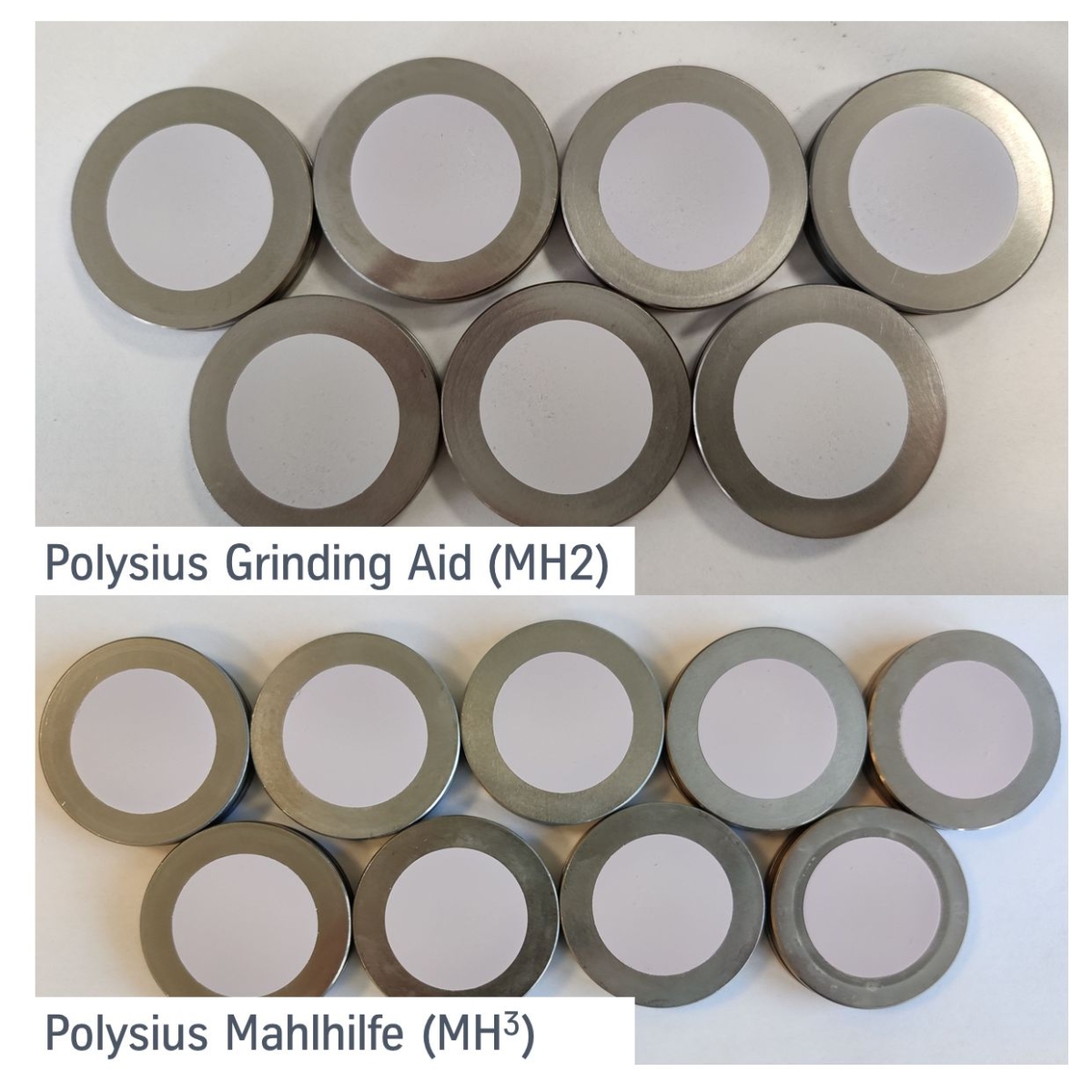

In the lab experiment, conventional cement grinding aid (CG), modified cement grinding aid (MG) were added into the cement raw materials with the dosage of 0.05%, the component of each cement grinding aid was shown in Table 2.

The cracked clinker and slag, gypsum, pozzolanic stone, fly ash, limestone were prepared with 5 kg, and grinding in the Φ 500 mm × 500 mm lab ball mill with each cement grinding aid. The cement samples were ground to 340±10 m2/kg.

The industrial experiment was carried out at the China Resource cement company, with the 180 × 160 mm roller mill and the Φ 4.2m × 13 m ball mill. Each grinding aid was added in 8 h, the cement composition was the same as the lab experiment.

The material flow time of the material in the mill was detected by the fluorescein sodium method, the fluorescein sodium was added from the entrance of the ball mill, and the sample was taken at the exit at a certain time. The UV spectrophotometer was used to detect the sodium fluorescein content of the sample, and the corresponding time for detecting the sample containing sodium fluorescein was the time the material passes through the ball mill.

The particle size distribution of the cement sample was tested by a Micro trac Laser particle size distribution analyzer. Ethanol was used as the dispersive medium. The specific area, the 45 μm cement residue and the other physical tests follow the GB 175-2024.

3. Result and discussion

3.1 Surface tension

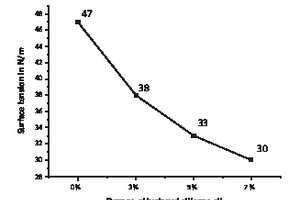

When the cement grinding aid was added, the ethanolamine adsorbed on the surface of the cement particles, reduced the surface energy of the particles, improved its grindability, and thus play the role of grinding aid [11]. The lower the surface tension of the ethanolamine, the better the effect of reducing the surface energy of the cement particles. The effect of hydroxy silicone oil modified on the surface tension of the ethanolamine solution was shown in Figure 1. With the increase of the amount of hydroxy silicone oil added, the surface tension of the ethanolamine solution decreased gradually, and the reduction of surface tension decreased when the dosage of hydroxyl silicone oil was greater than 5%. The results showed that the addition of hydroxyl silicone oil reduced the surface tension of the ethanolamine solution and improved the grinding aid performance of the ethanolamine solution.

3.2 Repose angle

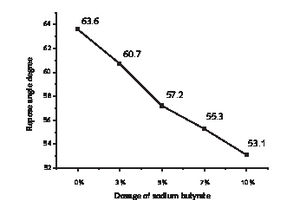

The repose angle of the powder characterized the dispersion of the powder particles. The adsorption of the cement particles by ethanolamine neutralizes the electrostatic adsorption between the cement powder particles and avoided their agglomeration [12]. Sodium butyrate adsorbed on the surface of the cement powder particles by the carboxyl group, and the dispersion of the fatty group improved the dispersion between particle and particle. The effect of the addition of sodium butyrate on the influence of alcohol amine on the repose angle of the cement powder was shown in Figure 2. The repose angle of the cement powder decreased with the increase of the dosage of sodium butyrate, which indicated that the addition of sodium butyrate increases the dispersion of the powder then improved the performance of cement grinding aid.

3.3 Lab ball mill experiment

Two cement grinding aids were prepared according to the above Table 2, then added separately to the cement raw material by dosage of 0.05%, both samples were ground in the above lab ball mill for the same time. The physical test result was shown in Table 3, when the MG was added, the specific surface area was increased by 12 m2/kg, because the incorporation of sodium butyrate reduced the agglomeration of cement powder, improved the grinding efficiency of fine powder, and thus increased the specific surface area of cement, the residue of 45 μm was reduced by 1.1%, because the addition of hydroxyl silicone oil reduced the surface tension of difficult grinding materials such as clinker and slag, making it easier to be broken under the impact of steel balls. The 3 d compressive strength increased 0.6 MPa and the 28 d compressive strength increased 1.3 MPa. This result implied that the addition of sodium butyrate and hydroxyl silicone oil improves the performance of the cement grinding aid.

3.4 Particle size distribution

Cement particle size distribution is an important index to characterize the grinding performance of the cement grinding aid. The addition of cement grinding aid usually improve the grindability of cement raw materials and reduce the content of coarse particles [13-14]. The reduction of over-grinding will also reduce the proportion of fine powders and narrow the peak of particle size distribution of cement. The effect of grinding aids on cement particle size distribution is shown in Table 4. After the addition of MG, the > 3μm fine powder content decreased, which was beneficial to the addition of sodium butyrate, reduce the agglomeration of fine powder so that to improve the efficiency of powder selection. The characteristic particle size decreased, indicating that the addition of the hydroxyl silicone oil improved the grinding ability of cement materials like clinker, slag. Moreover, the cement particle with 3~32 μm distribution increased when the MG was added, which belong to the result of cooperation of sodium butyrate and hydroxyl silicone oil.

The Industrial experiment of both CG and MG was carried out in the closed-circuit combined grinding process. The test time of each grinding aid was 8 h, and the transition period was 2 h when the grinding aid was switched. The grinding aid was added from the feed belt before entering the roller press to make sure that the grinding aid can enter the roller press system first to observe its effect on the entire grinding condition. With the different grinding aids were added, the data of the roller press system was shown in Table 5. After switching to the MG, the stable bunker level decreased with the fan remaining unchanged, indicating that more fine powder could be selected by the powder separator, with the dispersion effect of MG, decreased the agglomeration of cement powder, less fine powder turned back to the stable bunker, improved the grinding effect of the roller material, the electric current of the roller press increased and the vibration decreased, which mean that the efficiency of the roller press system was improved. When the fine powder between the roll decreased, the vibration of the roller decreased and the roller press system became more stable, the gap of the roller turned bigger so that more material can be ground. The efficiency of the roller press system was improved.

The ball mill system data was shown in Table 6. The production increased by 15 t/h, and the power consumption decreased by 1.7 kW·h/t after the CG was switched to MG. With the addition of sodium butyrate, the MG had a better effect of disperse cement particles, reduced the over-grinding effect of cement powder, more fine cement powder ran out of the ball mill, with a higher specific surface area, then the electric current of both the export fan and the storage entrance fan increased, corresponding to the increase in cement production. As the dispersion of cement particles improved, less hard materials like clinker, slag were covered by fine particles, with the addition of hydroxyl silicone oil, the MG absorbed on the cement particle easily, then decreased the surface energy, so that they can be ground more effectively. Although the dispersion of cement particles improved, their flowability in the ball mill didn‘t change significantly because there were two activated rings in the second ball mill bin, delay the flow of the cement particles. The cement was ground more effectively and then was fine enough to be selected out of the ball mill, then the electric current of main motor decrease when the MG was added. The result showed that the MG has a better effect on the grinding system.

The particle distribution of the cement sample in the industrial test was different from that of the cement sample in the laboratory mill test. The material in the laboratory mill was obtained after a certain period of grinding in a closed system, and the material had a longer grinding time. In the industrial process, the material was continuously produced in the combined grinding system of roller press, powder separator and ball mill, and the grinding time of the material was shorter than the lab ball mill process. The particle size distribution of the cement sample of the industrial experiment was analyzed in Table 7, there was lower <1 μm and <3 μm content than that of the lab ball mill because of the powder selection system of the industrial mill, the fine powder was selected out of the grinding mill. Cement sample with MG had a higher 3~32 μm content and a smaller characteristic particle size, corresponding to the lab ball mill result, but with a greater increasing range of 3~32 μm content, with the air flow in the ball mill, the MG showed a better dispersion so that the cement powder reduced the coating of fine powder then was ground more effectively. The MG had a greater grinding effect in the industrial experiment than in the lab ball mill experiment.

In the lab ball mill experiment, the performance of different grinding aids was compared at the same grinding time, and in the industrial experiment of plant, the same specific surface area of the output cement needed to be controlled to ensure the stability of the cement quality. The physical data of the cement samples for the industrial experiment were shown in Table 8, after switching to the MG, the residue of 45 μm was reduced by 1.2%, consistent with the trend of the lab ball mill experiment result. The 3 d compressive strength increased by 1.9 MPa and the 28 d increased by 2.3 MPa, both age strengths were higher than the lab ball mill experiment result, with a higher content of 3~32 μm particle size distribution, more cement particle hydrated effectively, providing greater performance. The MG had a better performance both grinding aid ability and cement strength enhance ability.

Conclusion

In this work, a hydroxyl silicone oil and sodium butyrate modified cement grinding aid were studied, and the following conclusions can be drawn:

The addition of hydroxyl silicone oil decreased the surface tension of the ethanolamine solution, then enhanced the absorption of the cement grinding aid;

The addition of sodium butyrate enhanced the dispersion effect of the cement grinding aid;

The hydroxyl silicone oil and sodium butyrate modified cement grinding aid (MG) reduced the residue of 45 μm, increased the Blaine specific surface area of the cement samples both in lab ball mill and industrial experiment;

The MG improved the efficiency of both roller press and ball mill system, the output was increased by 15t/h and the power consumption decreased by 1.7 kW·h/t;

The MG reduced the fine powder, increased the 3~32 μm content of cement so that provided a higher compressive strength;

Overall, MG promotes the grinding effect of the roller press on the material, increasing the particle content of cement from 3 to 32 μm, and improving the strength of cement through physical action without increasing the content of ethanolamine.