Eggersmann FUEL: landfill diversion meets fuel substitution

Maximum landfill diversion should not be seen as a challenge in waste management but rather as a chance for a more sustainable clinker production. Only the biogenic organic components in RDF do not contribute to global warming. With the Eggersmann FUEL process not only the recyclables in MSW are converted to RDF but also the organic fraction will be an important part of high-quality alternative fuel. Thus, a landfill diversion of up to 80 % and high primary fossil fuel substitution rate can already be achieved today. All it needs is the MSW owners / landfill operators and the cement producers to join forces and act as a team.

Moisture as a common challenge at the landfill and for clinker production

In order to use refuse derived fuel (RDF) on a large scale in clinker production, it must meet a number of requirements. Besides ash, sulphur and chlorine limits, to name only a few, moisture is in most cases the most important parameter for RDF quality. Moisture not only reduces the calorific value of the substitute fuel, but the evaporating water increases exhaust air volumes and could limit throughput or RDF substitution rates. The Municipal Solid Waste (MSW) in many countries contains significant amount of food waste causing overall moisture in MSW of 50% and higher. As organic matter, food waste consists to a large degree of water. It is precisely this water that causes the difficulties with RDF as well as the major problems of landfills – highly contaminated leachate water and landfill gas. With anaerobic conditions in a landfill body, the degrading organic will produce large quantities of methane and nitrous oxide. Collecting and cleaning leachate water is neither an easy nor a cheap task. Unfortunately, there are more dumpsites / landfills without an impermeable bottom than those with leachate collection. Without leachate collection not only the soil below but also the ground water as well as nearby streams and rivers are poisoned through landfill leachate discharge. Besides the impact of landfill gas to global warming, landfill gas can easily ignite. Smouldering or burning areas on landfills are causing big clouds of black smoke which are poisonous for nearby residents, cattle and farming. Leachate water collection and treatment as well as gas extraction and burning have to be continued long after final closure of the landfill. With dumpsites and landfills we are leaving the next generations a costly legacy where none of them had any benefits or a say in it. This is especially interesting, since the main cause of the problems for the landfill operators could be turned into a benefit for the clinker producers. 80% landfill diversion by MSW processing to RDF will not only lower the emissions from landfills but also supply the clinker producers with sustainable RDF.

Eggersmann FUEL: Biological drying as the key to success

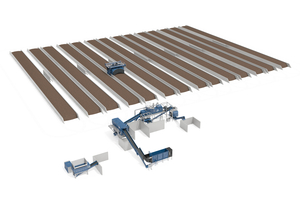

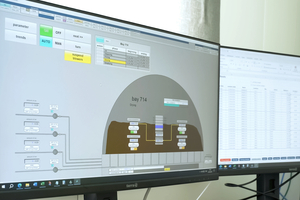

Targeted biological drying is becoming increasingly established as a one of the processing steps for MSW. It dry-stabilises the MSW and can reduce the landfill mass by up to 50% – but the advantages for the cement industry are often overlooked. If biological drying is carried out correctly, municipal waste can be turned into a quality substitute fuel with a particularly high calorific value. Eggersmann Anlagenbau has developed the Eggersmann FUEL, a tailor-made solution for the challenges faced by both the cement industry and landfill operators. In this process, the pre-shredded municipal waste is collected in lanes and dried using the CONVAERO system. This system consists of a semi-permeable membrane, a floor with ventilation and drainage system, and a BACKHUS CON turner. The latter ensures that the material is mixed regularly. The new surfaces allow for fast moisture evaporation. During turning, the automated machine can pick up the CONVAERO membrane at the front and deposit a new one behind it. This creates a virtually closed system. The heart of the CONVAERO system is the CONVAERO membrane. It prevents not only the escape of emissions – especially unpleasant odours – and the ingress of rainwater but also protects the material from being carried away by wind. At the same time, however, water vapour can escape from the inside through the membrane to the outside. To evaporate the water and sanitise the material by killing harmful microorganism, the natural heat generated by the organic degradation process is completely sufficient and no external heat source is required. Regular turning prevents the forming of lumps which could have an anaerobic core. Since most of the water evaporates, only extremely small amounts of leachate need to be treated as well. This leachate is collected by a drainage system in the floor of the lane. The floor also has ventilation to supply the drying process with air to remove the moisture. The most important process parameters are continuously recorded and displayed in real time. This allows the moisture content to be adjusted precisely to the customer‘s requirements. As a rule, reducing the water content to around 20% is sufficient to produce a substitute fuel with a high calorific value. One of the Eggersmann plants with the CONVAERO system, for example, reduces the moisture content from 55% to 20% in just 21 d. Together with the refinement, the calorific value is increased from only 2500 kJ/kg to a full 14000 kJ/kg. The required calorific value can be achieved by adjusting the drying time as well as the mechanical refinement process.

Up to 80% landfill diversion

“Due to its low water content, Eggersmann FUEL can easily be used in large quantities as a substitute fuel. Cement kilns in Germany and Austria operate since years successfully with very high total substitution rates of 60% in average,” explains Engineer Jan Gressmann as the expert for biological drying of the business unit biological waste treatment systems at Eggersmann. “This is also an advantage for landfill operators. Drying alone reduces landfill bound waste by up to 50% – the use as a substitute fuel can even achieve a landfill diversion of 80%.” This significantly extends the lifetime of landfills. For cement production, the use of dried biomass also means a better CO2 balance with lower taxation. After all, biomass is a renewable energy source. Regarding Gressmann, this makes the Eggersmann FUEL special among the available RDF solutions: “Many substitute fuels are produced solely through mechanical processing, and the fines – containing the majority of organic matter – are separated as an impurity due to its moisture content. Much more landfill residue remains, and the total calorific value converted to RDF per ton of MSW is lower. In short, an incredible amount of potential is literally being wasted.”

Scalable process due to modular design

Drying in lanes enables a modular plant design. Additional lanes can be added at any time as required. Projects are therefore scalable according to initial and over time increasing demand. In order to accelerate the implementation of new plants around the world, Eggersmann now also offers system solutions designed for throughputs of 150, 250, 500 and 100 t/d day. “These are essentially fully designed MSW to RDF plants that only need to be installed at site with very short lead time,” Gressmann continues. “These plants are interesting for any region without waste separation and any budget. Especially in partnership with a cement plant, they can be implemented economically anywhere.” Eggersmann has already built plants with CONVAERO drying in countries such as Indonesia, Romania and Iraq. The plant in Iraq has been successfully producing RDF since 2020 and has already been extended. For customers with the need for fully enclosed operations, Eggersmann offers the drying in fully automated tunnels as an alternative to the CONVAERO system with lanes and membrane. Similar to the CONVAERO approach the tunnel concept can be scaled by the number and dimensions of tunnels.