Innovative research project: Steel mill slag is being turned into a climate-friendly binder for cement

As a partner in the “WAGEOS2SHS” (Wassergranulation von Elektroofenschlacke zu Schwarzem Hüttensand; water granulation of electric furnace slag to black granulated blast furnace slag) research project, Holcim is testing another promising approach to decarbonizing the construction industry and cross-sector circular economy.

As part of the joint project, Holcim is working with partners Lech-Stahlwerke GmbH, recycling company Max Aicher Umwelt GmbH, and Märker Zement GmbH to develop a novel, CO2-reduced clinker substitute. The so-called “black granulated blast furnace slag” is produced from electric furnace slag and is intended to enable the cement production of the future as a climate-friendly binder.

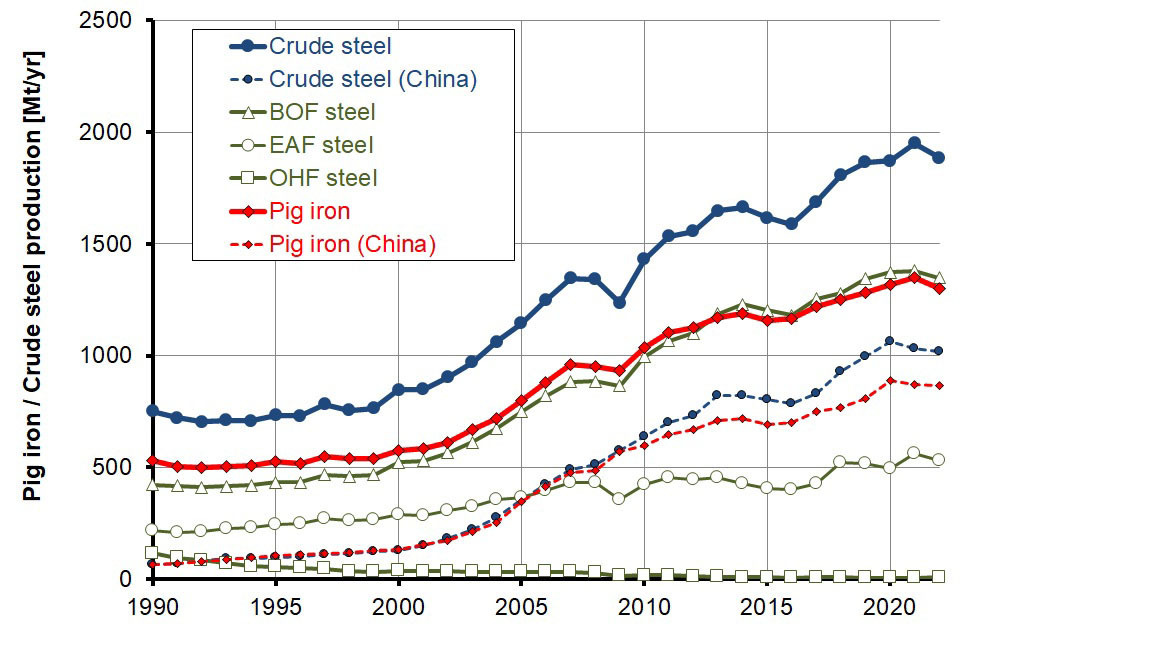

The German steel industry is undergoing profound change. With the gradual decommissioning of traditional blast furnaces and the increasing establishment of electric arc furnaces powered by renewable electricity, conventional blast furnace granulate will no longer be a proven and important component in cement production in the future. Holcim is addressing this challenge with its partners in the research project: In order to avoid an increase in the consumption of natural resources, the aim is to make use of electric furnace slag.

The project focuses on the production of “black granulated blast furnace slag” from electric arc furnace slag (EAF slag) using an innovative water granulation process. The result is a binder made from an industrial by-product which, thanks to its properties, can replace blast furnace slag and thus save energy and CO2 in the future. “The use of water-granulated electric arc furnace slag as a binder is another step for us on the path to becoming a climate-neutral company,” says Dr. Eberhard Liebig, Head of Product Management Cement at Holcim (Germany) GmbH.

Holcim’s research focus in the project includes:

The development and production of cements using “black granulated blast furnace slag”

The systematic evaluation of the performance of these new types of cement in concrete

Comprehensive analyses of environmental compatibility and the preparation of life cycle assessments (LCA)

The creation of a database for possible future building authority approval

Funded by the Federal Ministry for Economic Affairs and Climate Protection as part of the “Decarbonization in Industry” program, supervised by the Competence Center for Climate Protection in Energy-Intensive Industries (KEI), Holcim and its partners are making another important contribution to the building materials transition with this transformation project.