Research project “DRI-EOS”: New electric furnace slag for CO2-reduced cement

With its SALCOS program, Salzgitter AG is a pioneer in low-CO2 steel production and has thus taken a leading role in decarbonization.

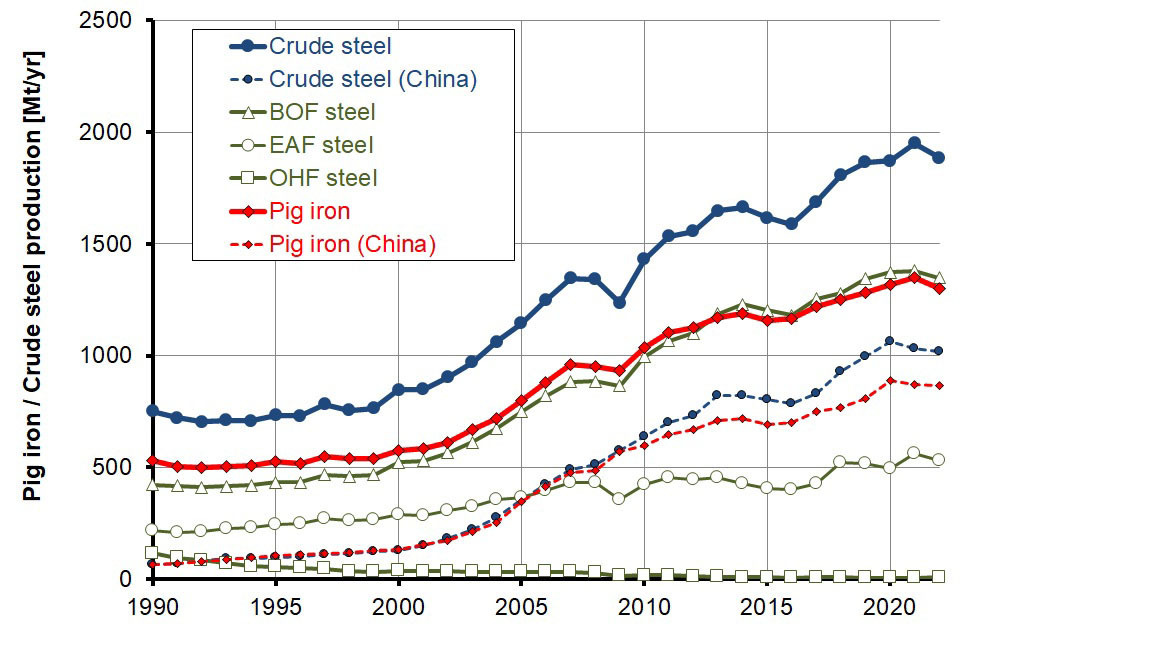

Due to the new low CO2 process route via direct reduction of iron ore (DRI) and subsequent melting in the electric arc furnace (EAF), a different type of electric furnace slag (EOS) is produced. This must be modified accordingly in order to continue to be used as a valuable and sustainable raw material.

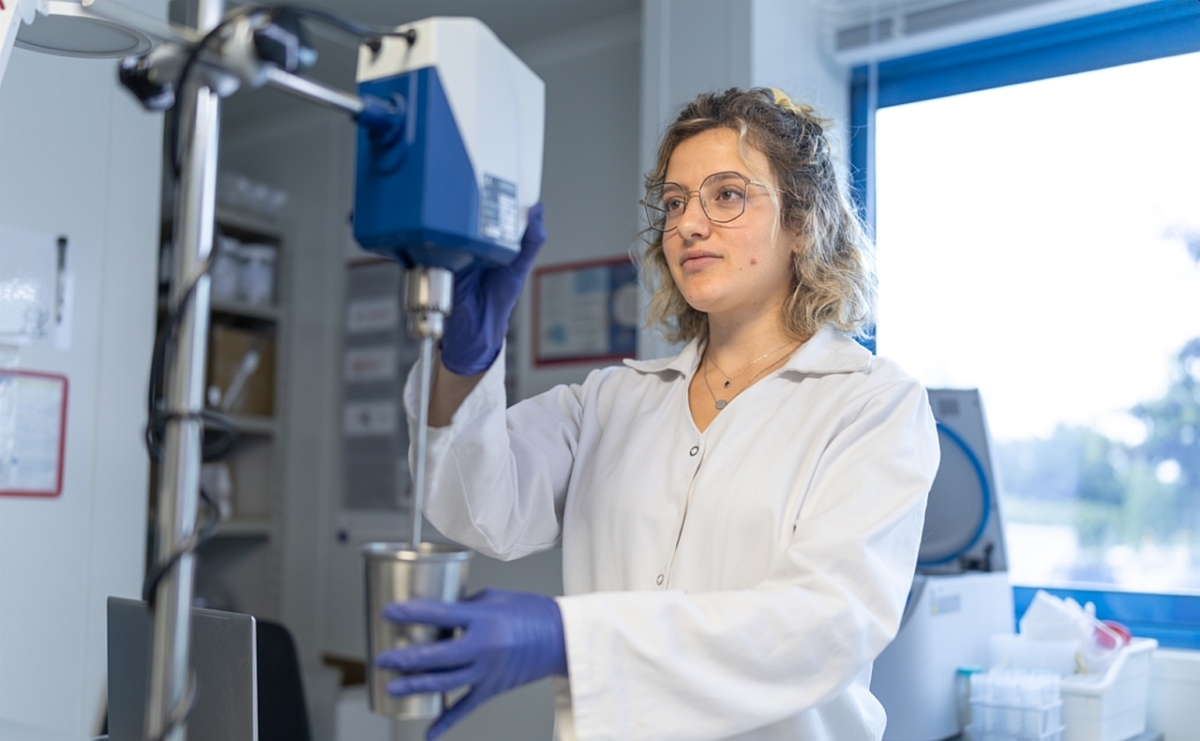

How the new type of electric furnace slag can be used in the future, especially in the cement industry, as a CO2-saving clinker substitute instead of today’s granulated blast furnace slag, is the subject of the “DRI-EOS” research project now launched. This is funded by the German Federal Ministry of Education and Research (BMBF) and coordinated by the FEhS Institute. The other partners are Salzgitter Mannesmann Forschung GmbH (SZMF), the Federal Institute for Materials Research and Testing (BAM), Friedrich Rohstoffe GmbH, Holcim Deutschland GmbH and LOI Thermprocess GmbH. The project will run for four years.

Ulrich Grethe, Head of the Steel Production Division of Salzgitter AG, sees the project, which is being handled on the Salzgitter side by Salzgitter Mannesmann Forschung GmbH, as an important contribution to the Salzgitter Group’s orientation towards the circular economy: “The results of the project should help us to ensure that the finite resources extracted for steel production continue to be used as optimally as possible in the economic cycle in future, minimizing the use of additional resources.”

For Thomas Reiche, Managing Director of the FEhS Institute, the research project is also another important contribution to the sustainable circular economy: “The recently presented second part of the current world climate report shows: “We must now intensify research in order to further reduce CO2 emissions with innovative technologies and strengthen the economy at the same time! With “DRI-EOS”, together with our partners we want to create the conditions for the high-quality by-products from the steel industry to be used in the future as resource-saving and low-CO2 building materials in the cement and concrete industries.”