Lime kiln system for burning carbonate rock, and method for converting a GGR shaft kiln into a lime kiln system comprising a shaft kiln

(22) 25.04.2022

(43) 03.11.2022

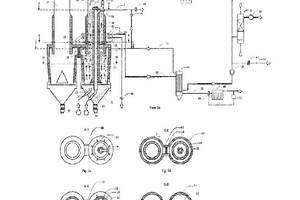

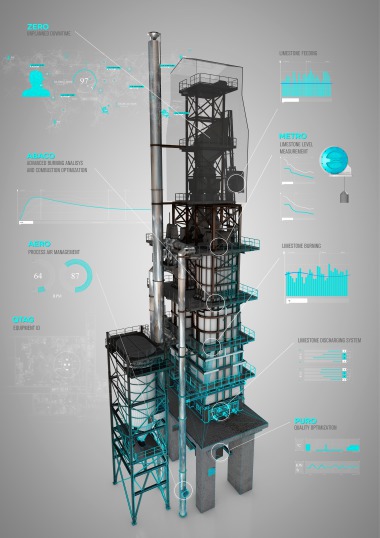

(57) The invention relates to a lime kiln system (4) comprising at. least. one shaft. kiln (1) for burning and cooling material, such as carbonate rock. The lime kiln system (4) comprises two shafts (2a, b) and a channel (19) which extends between the two shafts (2a, b), and the shaft kiln (1) comprises precisely one of the shafts (2a, b). The shaft (2a, b) has a material inlet (3) for admitting material to be burned into the shaft (2a, b) and, in the flow direction of the material, a pre-heating zone (21) for preheating the material, a burning zone (20) for burning the material, a cooling zone (22) for cooling the material, and a material outlet (40) for discharging the material out of the shaft (2a, b), wherein the channel (19) has a closure device (18) for closing the channel (19) in terms of gas flow so that a gas flow between the two shafts (2a, b) through the channel (19) is prevented by the closure device (18). The invention also relates to a method for converting a parallel flow counter current regenerative shaft kiln comprising two shafts (2a, b), which are connected together in terms of gas flow via a channel (19), into a lime kiln system (4) comprising at least one shaft kiln (1), each of which has precisely one shaft (2a, b), said method at least having the step of: – closing the channel (19) in a gas-tight manner by means of a closure device (18).

(71) Maerz Ofenbau AG, Richard-Wagner-Str. 28, 8002 Zürich (CH); thyssenkrupp Industrial Solutions AG, ThyssenKrupp Allee 1, 45143 Essen (DE); thyssenkrupp AG, ThyssenKrupp Allee 1, 45143 Essen (DE)

(84) ARIPO (BW, GH, GM, KE, LR, LS, MW, MZ, NA, RW, SD, SL, ST, SZ, TZ, UG, ZM, ZW), Eurasian (AM, AZ, BY, KG, KZ, RU, TJ, TM), European (AL, AT, BE, BG, CH, CY, CZ, DE, DK, EE, ES, FI, FR, GB, GR, HR, HU, 1E, IS, IT, LT, LU, LV, MC, MK, MT, NL, NO, PL, PT, RO, RS, SE, SI, SK, SM, TR), OAPI (BF, BJ, CF, CG, CI, CM, GA, GN, GQ, GW, KM, ML, MR, NE, SN, TD, TG)