Proposal for a new kiln process for burning of lump lime

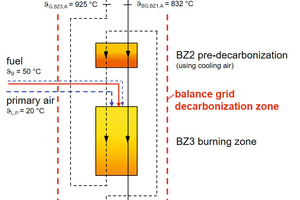

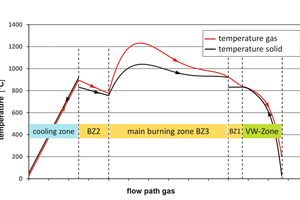

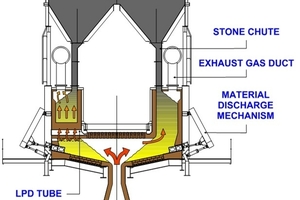

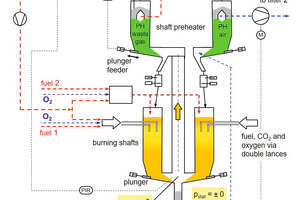

The proposal described below for a lime kiln is based on an idea which is more than 20 years old: firstly, utilisation of the calcining potential of elevated-temperature lime-cooling air, in order then to use the oxygen content of this lime-cooling air (enriched with a small amount of CO2) for burning. For this purpose, it would be necessary to develop a kiln concept in which the hot lime-cooling air is brought into contact with limestone adjusted to the starting temperature for calcining (approx. 820 to 830° C). In the PFR kiln, for example, the lime-cooling air, which should be set at a low flow, is heated almost to the lime temperature at the outlet from the calcining zone. In the PFR kiln, however, this lime-cooling air is only drawn through the waste-gas shaft without being used as combustion air. This idea originates from a period in which the author was intensively involved with the lime-burning process. A diagram of such a kiln process was quickly drawn (Figure 1). Its translation into an implementation-capable kiln concept began to appear ever more difficult as knowledge of lime kilns increased, however. Calculations of energy flows produced the result that a better specific thermal-energy consumption than when using a state-of-the-art PFR kiln is not possible. The basic idea was, for this reason, not pursued further. The topic of “CO2-neutrality” has moved to the foreground in the lime industry, too, for some time now. Even the old engineers‘ adage that “electricity is there for light and power” appears no longer to be true, since there have also been proposals for electrical heating of lime kilns. This then changes the perspective on concepts which, even only a few years ago, appeared of little rationality, and even indirect heating of the burning charge has, for example, been suggested. The goal is to obtain the CO2 that inevitably results from the calcining of the CaCO3 unmixed with combustion waste gases. This pure CO2 would then be used for other processes or, possibly, liquefied and stored underground. Important in this context appears the concept of a so-called oxyfuel kiln based on combustion using pure oxygen [1]. Here, again, the objective is a highly concentrated CO2 kiln waste-gas. Against this new background, the old idea was again taken up, but under the stringent requirement of a “continuous process”.

The current state-of-the-art

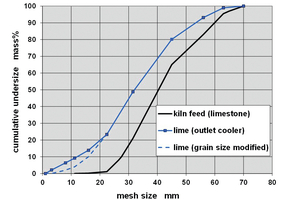

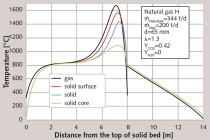

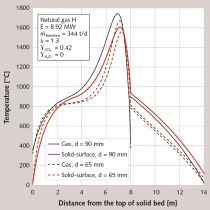

Benchmark for any proposed new lime-burning process is the PFR kiln. This type of kiln achieves the lowest possible specific thermal-energy consumption. A whole series of significant improvements to this kiln type have taken place in recent years. Achievable specific thermal-energy consumption depends in every case on the chemistry of the limestone charged and the residual CO2 content of the lime product obtained. The data shown in Table 1 are used in this work.

A state-of-the-art PFR kiln can achieve for these analytical data a specific thermal-energy requirement of...