LOGiQ combines yard management and weighing technology fully automatically

Schenck Process, a specialist for process-critical bulk materials applications, offers the LOGiQ yard management system, a cloud-based software solution that combines smooth and efficient truck loading operations with fully automated weighing of bulk materials - supported by log-on terminals, which are also part of the LOGiQ product family.

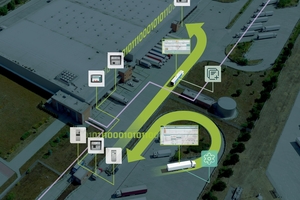

LOGiQ is a proven system in the cement and steel industry. However, the solution is also suitable for yard management in other segments of industrial production. LOGiQ handles all logistical steps from the entry of an authorized truck onto the company premises to the exit in a seamless process. The software system monitors and controls access, supports weighing processes, ensures correct loading and records all relevant data without delays. All information is integrated into the ERP system, for example SAP, to provide up-to-date sales and administrative data.

Multilingual terminals included in the LOGiQ complete package

Access is controlled via LOGiQ registration terminals, which are intuitive to use and available in several languages on request. The truck drivers operate these terminals themselves and record their weighing processes and all steps during loading and unloading. The processes run automatically without the need for manual intervention by staff: “zero-touch fulfillment”. This reduces the susceptibility to errors in the process and increases safety. The basic need for personnel on the factory premises is also noticeably reduced thanks to automation. In addition, the responsible employees and support staff at Schenck Process can access and support all data in real time, regardless of location, if required.