Maximum energy efficiency with unrestricted reliability

Aerzen is significantly expanding its product portfolio in the higher-pressure range and has added innovative compressors from the standard segment for differential pressures of up to 13 bar. The packages consistently meet customer and market requirements and offer new, economical perspectives for conveying and compressing air and special gases. Energy savings of more than 10% are possible.

Compressed air is omnipresent in industry and has become an integral part of many applications. However, it is also a very cost-intensive medium – and therefore one which offers an important lever for energy savings. This is precisely where the new compressed air packages from Aerzen come in. The compressors combine excellent performance with maximal energy efficiency and set new standards in compressed air technology. Thanks to their high power density and reliability, they keep life cycle costs low and ensure significant cost reductions – an ideal solution for making processes even more cost-effective, sustainable and efficient.

Tradition meets innovation: compressed air taken further

For more than 160 years, Aerzen compressor technologies have been considered pioneering in the conveying and compression of gases. In the compressed air sector, the innovation and technology leader has, up until now, made a name for itself primarily as a supplier of stages and special packages. By adding the oil-free and oil-injected screw compressor series with pressure capacities up to 13 bar, the company is positioning itself in the compressed air technology sector and is significantly expanding its expertise.

The new packages complete the portfolio in the higher pressure range and open up additional fields of application – be it in food technology, the beverage industry, chemical and process engineering, the textile industry, medical and pharmaceutical technology, electronics and semiconductor production or in the cement and lime industry. The new packages have been developed to meet the highest demands and can be used wherever working air, instrument air, workshop air, process air or control air for pneumatic control systems is required.

DS series: double-stage, oil-free screw compressors

The purity of compressed air is often crucial, as it influences the quality of the processes used to manufacture high-quality products. Oil-free operations are therefore vital for many processes and a must in terms of safety, reliability and availability in particularly sensitive areas. The new double stage screw compressors of the DS series compress entirely oil-free in accordance with ISO 8573-1, class 0 and reliably provide 100 % clean process air. This ensures complete product purity.

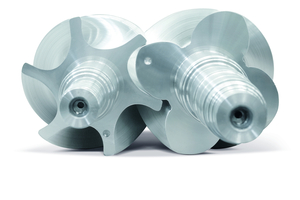

The directly-driven compressed air packages were designed for maximum energy efficiency, minimum maintenance effort/costs and extreme durability and they ensure outstanding performance in almost all application areas at differential pressures of between 5.5 and 10.5 bar. Energy savings of up to 12 % are possible compared with other compressor models available in the market. This leap forward in efficiency is achieved through innovative compressor stages with new, highly efficient 4+6 rotor profiles in the low and high pressure stages, as well as motors with energy efficiency class IE4 or IE5. A VFD is integrated and ensures optimum operation with a large turndown.

The compact DS compressors are available in nine sizes for drive powers from 55 to 315 kW and volume flows from 180 to 2,920 m³/h and are also suitable for sensitive scopes of application in the food and beverage industry, in chemical and process engineering as well as in medical and pharmaceutical technology. The process air generation is of course PFAS-free, without compromising on performance and durability.

SI series: oil-injected compressors with permanent magnet motor

The SI series are new single stage, oil-injected air compressors. Thanks to an innovative screw compressor stage and a highly efficient IE5 class permanent magnet motor (PM motor), they achieve a very high efficiency of 96 % which enables significant energy savings to be made, even in partial load operation.

The rotor is connected directly to the compressor shaft, avoiding additional losses in the drive train. The required quantity of compressed air is adjusted as needed by means of a VFD. The ideally harmonised combination of a high-quality drive train and a highly efficient compressor stage results in particularly efficient operation of the entire package.

The PM motor technology works entirely without roller bearings. This eliminates the need for lubrication and the usual bearing replacement. The anti-friction bearings of the compressor stages are designed for a service life of at least 30000 hours, further reducing maintenance and service costs.

The new screw compressors are available in ten sizes from 7.5 to 75 kW and are used in numerous, sometimes demanding applications with differential pressures of 5.5 to 13 bar and volume flows of 17 to 726 m³/h. Pressure and operating temperatures are continuously monitored. This ensures stable and safe production processes. Other advantages of the SI series include its unique reliability, reduced maintenance requirements, compact design and low sound emission values with a sound pressure level of around 70 dB(A).

The optimal solution for every requirement

Every location, every company, every process has its own special features. Aerzen therefore offers a wide selection of finely graduated sizes and an enormous variety of customised accessories and spare parts components. The comprehensive range of options and modifications – including coolers, dryers, special motors, special materials, special oils and customised heat recovery systems – allows targeted adaptation to individual customer process requirements and particularly challenging climatic conditions and ensures the greatest possible flexibility in the design of machines and plants.

Optimum compressed air quality thanks to perfect air conditioning

One focus is the area of compressed air treatment. Compressors work with the ambient air. However, this contains impurities of various types, such as steam, dust or liquids. If these are not removed, problems are inevitable. Condensing water vapours, for example, can cause corrosion, which can damage components of the compressed air installation and lead to production interruptions. The result: increased operating costs due to failures. Aerzen‘s wide range of products for filtering, cleaning and drying the compressed air ensures high and constant compressed air quality in every process.

Safe, efficient and environmentally friendly compressed air generation

Aerzen air compressors have been developed to increase productivity and reduce operating costs. Thanks to the extremely compact design of the DS and SI compressors, the machine footprint is also reduced. The smart package concept even enables side-by-side installation, as operation and maintenance can be carried out from both the operating and rear sides. Transport by pallet truck, forklift truck or crane is possible without any problems.

In addition to the new DS and SI series, Aerzen also offers water-injected compressed air stages. The SW series packages with screw rotors made of high-alloy, corrosion-resistant stainless steel offer increased energy efficiency, reduced maintenance requirements and a unique water purification concept, and ensure oil-free compression up to 13 bar.

“Our declared aim is to offer our customers a full range of products, solutions and services. Our air compressors are state of the art and support you on your way to greater efficiency and process reliability. They therefore make an important contribution to sustainability and economic efficiency,“ emphasises Stephan Brand, Director of Marketing at Aerzen.