meca® clay: Transforming clays into high-performance SCMs

1 Context & motivation

The cement industry is undergoing a fundamental transformation. Driven by the need to decarbonize, the depletion of traditional supplementary cementitious materials (SCMs) like fly ash and slag, and the demand for regionally adapted raw materials, the sector is being pushed to rethink its technological foundations. In this context, SCMs are increasingly recognized as key to reducing CO₂ emissions and conserving resources. Natural clays are among the most promising future SCMs. They are abundant and mineralogically diverse, yet their low raw-state reactivity has limited their use. Mechanochemical activation addresses this challenge by transforming clays into highly reactive binder components [1-3].

The meca clay technology [4], developed by Polysius and SCHWENK Zement, offers a scalable, industrial solution for activating clays efficiently. It bridges the gap between scientific innovation and industrial application, enabling the use of local clays as a strategic resource. This paper outlines the scientific principles, material characterization, performance in cement systems, and industrial implementation – thus demonstrating how activated clays can become a cornerstone of low-carbon cement production.

2 From clay deposit to reactive binder

Clays are abundant and widely available near cement plants. Yet their lack of reactivity has limited their use in high-performance binders. While kaolinite-rich clays respond well to thermal activation, illite- and muscovite-dominated clays are more challenging. The central challenge, therefore, lies in transforming inert clays into reactive binder phases. This transformation requires a fundamental alteration of their internal structure, which is precisely the objective of mechano-chemical activation. By applying mechanical energy, the crystalline frameworks of clay minerals are disrupted, generating structural defects and amorphous phases with significantly enhanced reactivity.

This approach represents a paradigm shift. Rather than relying on industrial byproducts or high-temperature clay activation, cement producers can now activate local clay resources on demand – enabling the production of low-carbon, resource-efficient binders that are independent of global supply chains. Mechano-chemical activation thus opens the door to a new generation of regionally adapted, climate-smart cement technologies.

3 What happens during activation? – Scientific foundations

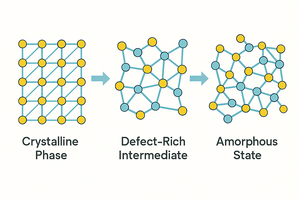

Mechano-chemical activation is often misunderstood as merely an intensified grinding process. [5] In reality, it is a targeted intervention into the microstructure of clay minerals, designed to fundamentally alter their reactivity. Inside the activation chamber – the polysius® Charger – a complex interplay unfolds, introduced through shear, impact, and compressive forces. This not only results in a reduction in the size of the clay particles. Their internal crystal lattices are disrupted, generating a high density of defects and dislocations. In parallel, amorphous regions begin to form as the long-range order of the mineral structure collapses, liberating new, energetically unstable surface sites that significantly enhance the material’s reactivity (see Figure 1). It is these defect-rich and amorphous phases that are capable of reacting with calcium hydroxide, enabling pozzolanic reactions – essential for strength development in cementitious systems.

4 From lab to cement

Mechano-chemical activation alters clays at the molecular level. To make the structural changes and enhanced reactivity visible and quantifiable, a combination of analytical techniques and practical performance tests are necessary that together provide a comprehensive understanding of the material’s behavior. Several methods can be used to characterize the structural transformation of clays: X-ray diffraction (XRD) reveals the loss of crystalline order; BET surface area analysis quantifies the increase in accessible surface; thermogravimetric analysis (TGA) provides insight into the extent of structural disruption; Fourier-transform infrared spectroscopy (FTIR) complements these findings by detecting shifts in Si–O and Al–O vibrational bands.

To fully capture how the activated clay will perform in a cement matrix, practical reactivity tests are essential: Isothermal calorimetry measures the heat released during the reaction with calcium hydroxide, offering a direct indication of the kinetics [6]; mortar tests provide compressive strength data and binder properties – important benchmarks for practical performance.

Introduced into a cementitious matrix, activated clays engage in pozzolanic reactions with calcium hydroxide released during clinker hydration. These reactions lead to the formation of additional hydrated phases, including low Ca/Si ratio C–S–H gels that contribute to strength and density, as well as C–A–S–H phases that enhance microstructural refinement. The formation of ettringite and carbo-aluminate phases further stabilizes the pore structure. In hardened concrete, compressive strengths comparable to or exceeding those of CEM II/A can be achieved even at clinker replacement levels of 20 to 30%. In addition, the denser microstructure improves resistance to chemical attack, e.g., chloride ion penetration, and carbonation.

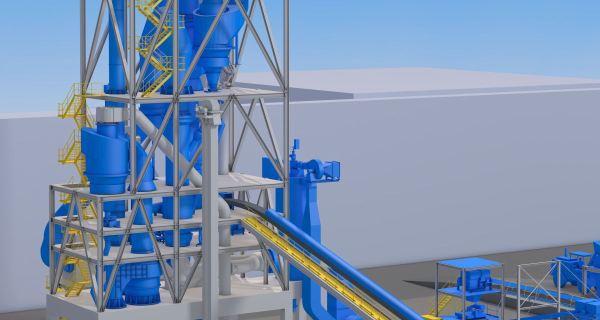

5 The polysius® meca® clay technology – mechano-chemistry at industrial scale

While mechano-chemical activation has demonstrated its effectiveness in laboratory settings, the true challenge lies in translating this process into a robust, scalable industrial solution. This is the objective of meca® clay, developed by Polysius and SCHWENK: A system that enables the efficient, continuous, and raw-material-flexible activation of clayish feedstocks. At the core of the technology is a high-energy activation process: The system uses a continuous, dry-operated activator – the charger – that applies a combination of shear, impact, and compressive forces to disrupt the crystalline structure of clay minerals. Unlike calcination [7], meca clay operates entirely at ambient or slightly elevated temperatures. This not only eliminates the need for fuel-based heat input but also significantly reduces CO₂ and other emissions. The modular design of the system allows for integration into existing cement plants, whether as a standalone activation unit or as part of a new grinding or blending line. The compact footprint of the meca® clay unit minimizes space requirements, and the design allows for rapid commissioning. As a result, the technology is suitable not only for large-scale plants but also for decentralized production models that rely on regional raw materials.

meca® clay is designed for full electrification, allowing all activation steps to be powered by electricity. This opens the door to a completely decarbonized binder production pathway, especially when combined with renewable energy sources such as solar, wind, or hydroelectric power. meca® clay does not alter the laws of thermodynamics. Consequently, the activation of clays requires specific energy inputs comparable to those of clay calcination. Electrical energy demands of 400-500 kWh/t are expected. When considering the pre-crushing and drying of the clay, the total energy consumption is estimated at around 550-650 kWh/t. It is important to note that no subsequent grinding process is necessary. The product from the charger can be directly blended into cement.

One of the defining strengths of the meca® clay technology is its exceptional raw material flexibility. It can process a wide range of clay types or mixtures of 1:1 and 2:1 clay minerals. Even mixed clays containing quartz or calcite can be effectively activated. This adaptability makes the technology particularly attractive in regions where conventional SCMs are scarce or where local clay resources have previously been overlooked. From both economic and environmental perspectives, the benefits are compelling. Replacing up to 43% of clinker with activated clay and limestone in LC3 or CEM II/C-M type cements can lead to substantial CO₂ savings – up to 370 kg/t of cement compared to CEM I. Table 1 provides an overview of the advantages of meca® clay.

6 Real-world applications & industrial experience

6.1 Pilot plant scale tests and laboratory results

To validate the industrial applicability of meca® clay, a series of pilot-scale trials and laboratory experiments were conducted using two high-energy density activation units with sizes of 30 l and 300 l. Various clay types – including kaolinitic and illitic/muscovitic materials – were processed. Laboratory analyses confirmed amorphization levels, and pozzolanic reactivity, as measured by heat flow calorimetry, reactive silica, and strength activity index (SAI). Compressive strength tests on cement blends containing 25% meca® clay demonstrated performance comparable to or exceeding reference CEM I. These findings underscore the robustness and scalability of the activation process and provide a solid foundation for full-scale industrial implementation. The results of three exemplary meca® clays (Clay A, B, and C) with different chemical (Table 2) and mineralogical composition (Table 3) are presented in the following.

While Clay A is dominated by 2:1 clay minerals, Clay B can be described as kaolinitic. Clay C, in turn, contains equal proportions of 1:1 and 2:1 clay minerals and an additional 20% of carbonates (calcite and dolomite).

After mechano-chemical activation in the charger, approx. 50% amorphous phase were formed at the expense of the crystalline components of all clay minerals, as well as some of the feldspars and carbonates (Table 3). Pyrite, however, is not decomposed.

The increased pozzolanic reactivity of the meca® clay products is demonstrated by the cumulated heat values determined in the R3 test (Table 4). Values above 300 J/g, and in some cases even above 400 J/g, are observed. This places meca® clay products in the upper range of natural pozzolans and above [6]. At the same time, there is a significant increase in reactive silica and alumina (Table 5), which demonstrates the improved solubility of activated phyllosilicates.

The results from mortar tests of meca clay-cement mixtures after 25% replacement of CEM I are shown in Table 6. The SAI after 7 and 28 d is approximately 100% or above. The water demand is 30-32%, which is higher than for the reference CEM I, but lower than typically seen for calcined clays.

The color behavior of meca® clays is demonstrated in Figure 2. Non-colored (brownish or gray) raw clays do not acquire a red coloration upon activation in the charger. In addition, reddish clays can be effectively color-optimized using a new, patent-pending integrated process.

6.2 Concrete testing

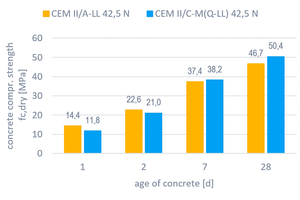

To assess the practical performance of meca® clays in real-world applications, a comprehensive series of concrete tests was conducted. The processing properties, strength development, and durability properties of standardized concrete compositions were evaluated. Figure 3 shows the strength development of concrete using two different cements containing 19% limestone powder each. In CEM II/C-M(Q-LL), 25% of the cement clinker was replaced by meca® clay. While the early strength in concrete using the low-clinker cement with meca® clay is slightly reduced, the strength after 7 and 28 days exceeds that of the reference CEM II/A-LL. Due to the higher specific surface area of meca® clay, the requirement for super-plasticizer was about 50% higher in order to achieve the same concrete consistency. All practical construction requirements regarding carbonation resistance, chloride migration resistance, and freeze-thaw resistance were also met using the low-clinker cement containing meca® clay.

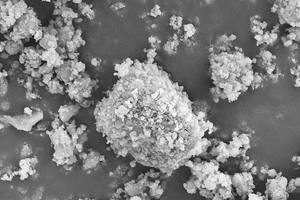

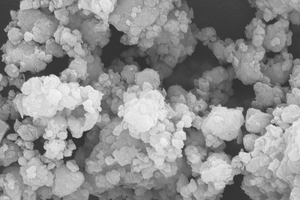

The improved workability of meca® clay-containing cements compared to calcined clay is based on two effects: First, the mechano-chemical treatment leads to the formation of agglomerated secondary particles (see Figure 4). Second, crystalline water is not expelled during activation but merely restructured within the phase matrix.

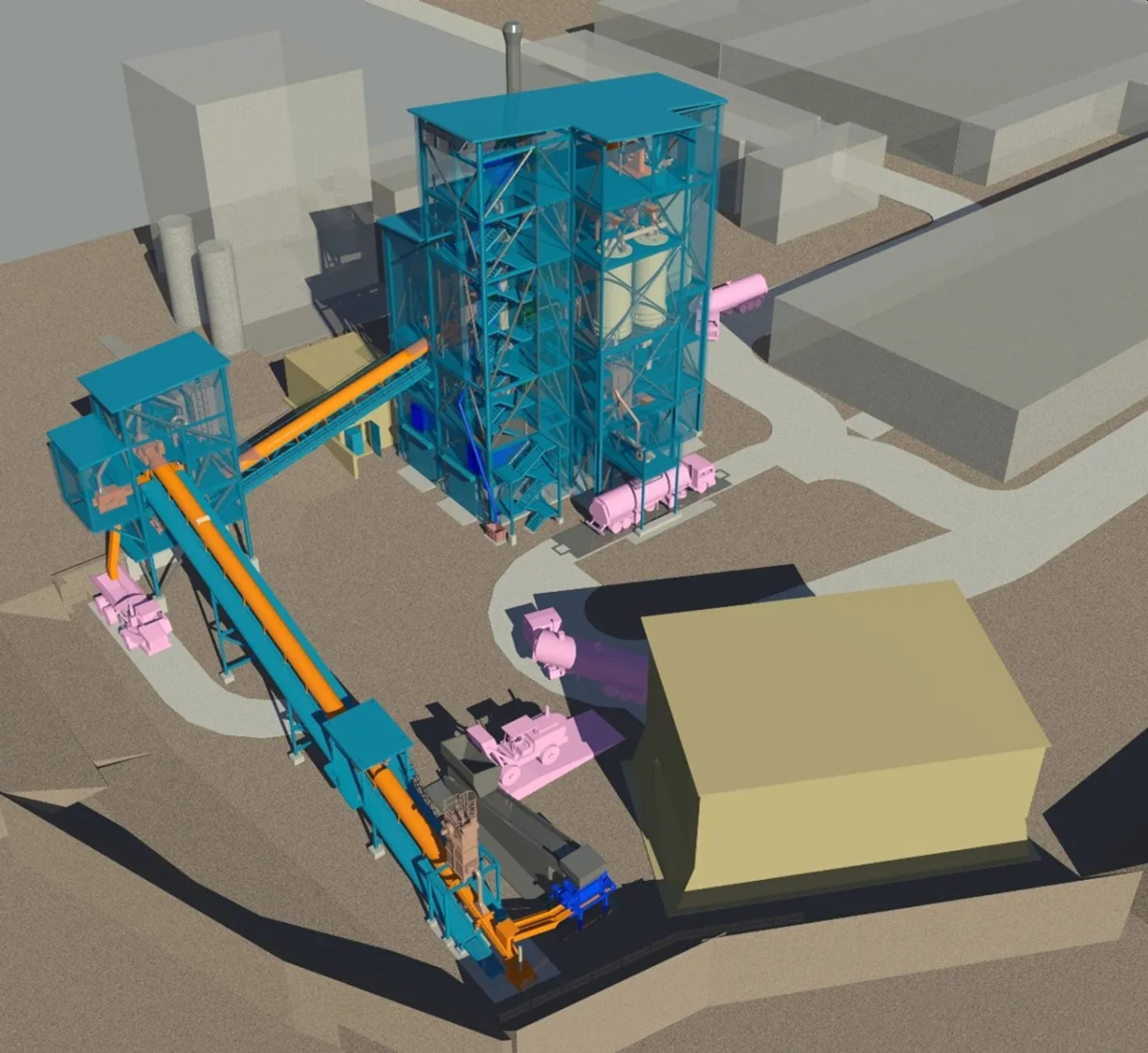

6.3 Allmeca – the world’s first industrial meca® clay production facility in Allmendingen/Germany [8]

SCHWENK Zement has chosen its Allmendingen site in southern Germany as the location for the world’s first industrial scale meca® clay facility. Commissioning is scheduled for spring 2026. In its initial phase, the plant will reach an annual production capacity of 50000 t, with the option to expand to 100000 t. The meca® clay technology enables the trans-formation of clay materials into highly reactive SCMs using electricity alone. By eliminating the need for calcination, up to 70% of the CO₂ emissions typically associated with clay activation will be avoided. This makes the technology not only a forward-looking solution for sustainable cement production, but also a key element in SCHWENK’s broader climate strategy across the entire value chain.

7 Business case analysis – market, economic, and regulatory drivers

The adoption of meca® clay as a sustainable alternative in the construction materials sector is increasingly supported by a convergence of favorable market conditions, cost dynamics, and regulatory incentives. The rising cost of carbon emissions, driven by increasingly stringent emissions trading schemes, has created a strong incentive for industries to adopt low-carbon or net-zero alternatives. meca® clay is well-positioned to benefit from this trend. Additionally, elevated market prices for clinker and cement further improve the financial attractiveness of partial substitution with meca® clay.

Referring to the business case, the economic viability of meca® clay is notably enhanced in regions where electricity prices are low. Given the energy-intensive nature of the activation process, access to affordable electricity significantly reduces operational costs, making it particularly suitable for provinces with favorable energy tariffs. meca® clay does not require a high kaolinite content, enabling the use of low-clay sources. This flexibility significantly enhances cost-efficiency and broadens the applicability, while contributing to the utilization of locally available or waste-derived materials.

meca® clay contributes to circular economy objectives by enabling the valorization of hazardous materials, e.g., asbestos-containing waste. This not only reduces landfill dependen-cy but also opens avenues for revenue generation through waste treatment and by-product utilization, reinforcing the material’s multifunctional value proposition. Public authorities increasingly offer economic incentives and subsidies to promote the use of sustainable construction materials. These policy instruments, including tax benefits, grants, and preferential procurement schemes, significantly improve the investment case. The high price levels of benchmark products in the construction and materials sector create a favorable environment for the market entry of innovative, cost-competitive alternatives. meca® clay, with its technical performance and sustainability credentials, is well-positioned to capture market share in this evolving landscape.

8 Perspectives and conclusion

meca® clay is more than a technological innovation – it is a strategic enabler for the transformation of the cement industry. Future developments lie in the exploration of new raw materials, the integration with emerging technologies, and the expansion into new markets and digital ecosystems. Beyond conventional clay deposits, attention is increasingly turning to alternative sources such as industrial residues, fractions from overburden, dredged sediments, or demolition waste. These materials could be transformed into valuable binder components through meca® – locally sourced, cost-effective, and environmentally sustainable.

The global availability of clays positions meca® clay as a technology with far-reaching implications. In many regions, suitable clays are located directly at or near cement plants, eliminating the need for complex supply chains or imported SCMs. This enables local value creation, strengthens supply security, and supports the development of sustainable infrastructure. This makes meca® clay a globally scalable solution for climate-resilient construction, offering a pathway to decarbonization that does not rely on thermal processing or CO₂-intensive high-temperature calcination, thus eliminating the need for thermal energy input and enabling a clean, low-emission production environment. Its tolerance for mineralogical variability and its compatibility with existing cement systems make it a highly adaptable and forward-looking solution.

The meca® clay technology developed by Polysius and the German cement manufacturer SCHWENK Zement demonstrates that this concept is not confined to the laboratory. It functions reliably at industrial scale, combining scientific precision with practical implementation. Its modular design and economic viability make it suitable for a wide range of plant configurations and market conditions. Case studies from different regions confirm that meca® clays can significantly reduce clinker content, enhance durability, and improve the overall environmental performance of cement.

This is demonstrated by the Allmeca plant in Allmendingen/Germany – the world’s first fully electric meca® clay plant. With commissioning scheduled for early 2026, Allmeca marks a decisive step toward industrial decarbonization and demonstrates the scalability of the technology under real-world conditions. Perhaps most importantly, it offers a globally scalable solution that can be tailored to regional resources and infrastructure needs – supporting local value creation while contributing to global climate goals. In this sense, meca® clay is more than a response to current challenges. It is a catalyst for a resilient, climate-smart, and future-ready cement industry.