Method of producing a hydraulic cement composition

(43) 26.06.2025

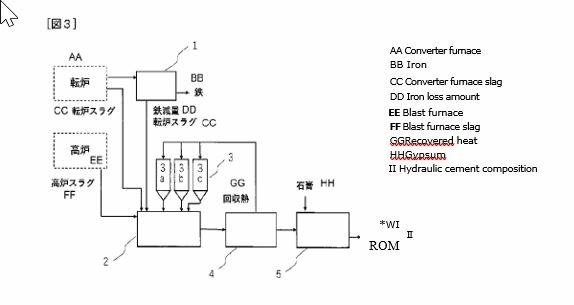

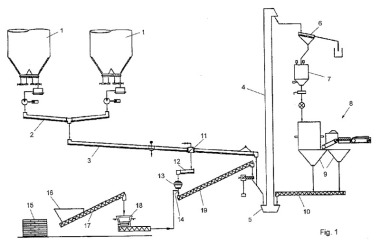

(57) A method of producing a hydraulic cement composition, comprising - providing a raw material that comprises> 18 wt.-% kaolinite, ≥ 15 wt.-% calcite and a combined content of muscovite and illite of < 20 wt.-%, - calcining the raw material to obtain a pozzolanic material, - mixing the pozzolanic material with Portland cement clinker so that the cement composition comprises> 50 wt.- % of the pozzolanic material and < 45 wt.- % of the Portland cement clinker.

(71) Holcim Technology Ltd [Ch] + (Holcim Technology Ltd)