MPA Lime: Collective voice for Great Britain’s lime industry

Net negative emissions by 2040: Five key levers are required to pave the way to CO2 negativity in Great Britain’s lime industry. In an interview with ZKG Cement Lime Gypsum, Mike Haynes, Director of MPA Lime, and Jon Flitney, Energy and Climate Change Manager in MPA Lime and MPA Cement, further outline the details of the MPA Lime Net Negative 2040 roadmap, give an overview on the use and development of lime products in the UK and explain specialties of the British lime industry in an international comparison.

The Mineral Products Association (MPA) is the UK trade association for the aggregates, asphalt, cement, concrete, dimension stone, lime, mortar and industrial sand industries.

MPA is the sectoral voice for UK mineral products, covering 100% of cement and lime production, 90% of aggregates production, 95% of asphalt and over 60% of ready-mixed concrete and precast concrete production.

The most recent profile of the UK Mineral Products Industry states that in 2021, the industry supplied £22 billion worth of materials and services to the UK Economy. It is also the largest supplier to the British construction industry, which had annual output valued at £178 billion. Industry production represents the largest flow of materials in the UK economy and is also one of the largest manufacturing sectors.

MPA represents the interests of its members and the wider industry with all levels of Government, regulators and a wide range of other stakeholders.

Key activities include:

Improving health & safety

Representing the sector

Raising awareness of the sector and its contribution to the economy

Gathering and presenting evidence and information

Influencing policy, regulation and legislation in the UK and EU

Protecting the industry’s licence to operate

Safeguarding and developing markets

Improving perceptions

Informing on markets and economic contribution

Influencing technical and design standards

Influencing supply chains

Encouraging innovation

Promoting the use of mineral products

Educating stakeholders to ‘Make the Link’ between mineral products and their use

MPA Lime is the trade association of the industrial mineral lime manufacturers in the UK and carries out the key activities above for the membership. As noted above 100% of the UK lime manufacturers are members of MPA Lime.

MPA Lime members include three businesses which manufacture industrial mineral lime products that are supplied to other businesses across the diversity of applications of lime, including exports of specialist products. In addition, MPA Lime has three Associate Member businesses producing industrial mineral lime which is used as an integrated part of their manufacturing process of products for which industrial mineral lime is essential.

The role of the MPA is to provide the members with the opportunity to come together on topics of mutual industry interest including legislation, regulations, standards and generic research to combine their strengths, and for MPA to provide a collective voice for the best interests of the members in advancing, protecting and representing the industry.

Full adherence to the requirements of UK legislation in the Competition Act 1998 and the Enterprise Act 2002 are ensured in every trade association meeting both online and in person.

There are well over 200 applications for lime products and for each of those, lime is often seen as one of the key ingredients, essential to achieve a desired objective of a process or a product.

Industrial mineral lime is used in a wide array of industries and the key ones include manufacturing industries with steel, glass, paper pulp & coatings, plastics and rubber as well as non-ferrous metals.

In food and water industries lime is used in drinking water treatment, sugar manufacture, soil treatment and fertilisation, as an animal feed ingredient and in fish, dairy and fruit farming.

In environmental applications lime is used in capturing acidic gas pollutants, neutralising acidic liquids, effluent treatment, as a sewage sludge modifier and in animal sanitation and contaminated land treatment.

In construction and civil engineering lime is used in mortars, renders and plasters, in the manufacture of rapid setting, high alumina cement and insulating, autoclaved aerated concrete (AAC) building blocks, bio-based construction materials and in sand lime blocks, as well as being an additive for asphalt and the basis for lime concretes and limewash.

With such a wide range of industries being supplied, demand variations mean that lime production tonnages in the UK have been relatively stable in recent years around the one million tonnes of products per year being supplied to the various markets.

In addition, the three Associate Members of MPA Lime who manufacture lime products for their own applications within their business, have key uses for lime products. One manufactures lime for their own steel production in the UK. The second manufactures lime to then process sugar beet into sugar, they also capture the carbon dioxide from their lime production and utilise it in the processing of the sugar liquor. The third manufactures lime to then produce precipitated calcium carbonate (PCC) and they too capture their carbon dioxide from the lime production, and it is used to make the PCC.

The British lime industry has quarries which are located on very high purity limestone and chalk deposits which provide the source of their kiln feed materials. This enables the production of lime products with a limited range, and low concentrations, of trace elements. Benefitting from this, export business has been developed, and in recent years has grown to achieve around 20% of total sales.

Close to home there are regular exports to Scandinavian and European countries for specific customers in key industries. There are also some applications for which the assemblage of trace elements and their concentration in the lime products are critical to achieve the desired effects, and the UK lime industry is one of the international sources for those businesses, with shipping locations served in the Middle East, India and the Far East, including China.

In addition, the ease and availability of shipping from the UK and the production of specialist lime products, with enhanced properties, achieved through specialist production processes, also means that the UK has export customers elsewhere, including in the Americas.

Health and Safety is the top agenda item for all industries, and this is no different in the lime industry. After that, the decarbonisation of lime production must be the greatest challenge and offering the most exciting developments and greatest hopes for the future. The UK lime sector was the first to trial lime production at full scale using hydrogen gas, in a government funded project that was managed by MPA Lime.

The British lime industry is working hard to be at the forefront of the decarbonisation of lime production and has come together to set out an ambitious target to accelerate decarbonisation and deliver ‘net negative’ carbon emissions by 2040. The MPA Lime Net Negative 2040 Roadmap, published in 2023, explains how the sector could go beyond net zero a decade ahead of the UK’s overall 2050 target, by deploying technologies such as fuel switching and carbon capture. The roadmaps five key levers also include the enabling actions required by Government and other industries in the supply chain, as well as achieving recognition of lime’s natural carbon-absorbing properties.

International research by the European Lime Association (EuLA), of which MPA Lime are members, has so far confirmed that around one third of the process carbon dioxide from lime production is reabsorbed from the atmosphere back into lime products – a process known as recarbonation – though this is yet to be recognised in carbon accounting methodologies.

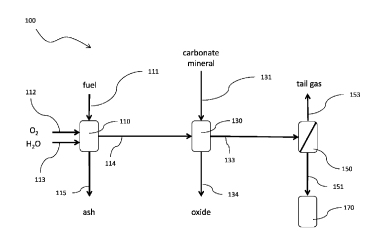

Combining the industry proposed developments with potential enabling action by Government and the effects of recarbonation, means that production of British lime could become net negative by 2040. Production of lime with captured process carbon dioxide and then the lime products absorbing carbon dioxide from the atmosphere in their application, means this would make a positive contribution to help address climate change by removing carbon dioxide from the atmosphere.

There are active, ongoing research projects utilising the lime cycle to develop methods of direct air capture of carbon dioxide, there are also projects investigating how lime can be used to change the pH of water and increase the absorption of carbon dioxide into bodies of water, even the oceans. Agricultural application of lime is also being studied to enhance the absorption of carbon dioxide into soils and to increase productivity which both could help address climate change.

In common with all industrial manufacturing processes, there are risks being addressed, including at the very beginning, the use of explosives to excavate solid rock. Then, making lime products with large machinery, which has physical risks, all the way through to the production, handling, storage, transport and delivery, combined with the reactive nature and the fineness of the finished powder products, makes respiratory inhalation, skin and eyes contact, all very serious concerns.

Therefore, the industrial occupational safety demands include diligence in risk management, process control and minimisation of close contact with the equipment and materials, and through automation, design and maintenance processes that provide protection as far as can be sustainably achieved.

MPA Lime is a member of the ILA as well as a member of the European Lime Association (EuLA). Both memberships enable wider sharing of non-commercial knowledge and information internationally, thus delivering the ability to discuss and learn about a variety of common areas of interest including, to name just a few, health and safety topics, industrial regulations, standards and policies, and technical innovations. National trade associations, like MPA Lime, benefit from these international memberships and working alongside others around the world to help promote, defend and support the industrial mineral lime sector.

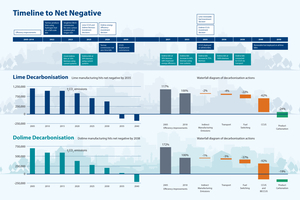

In June 2023 the MPA Lime Net Negative 2040 roadmap was published. It includes a diagrammatic idealised representation of the decrease in emissions that leads to the UK lime sector being fully decarbonised by 2040 and, when the benefits of recarbonation are considered, contributes net negative emissions. This sits within the wider context of the UK government’s aim for its economy to be net zero by 2050. Achieving the targets will require actions by government, third parties, the supply chain and the producers working together.

The main mechanism of emissions reduction is the UK Emissions Trading scheme (UK ETS), which requires reporting of direct CO2 emissions from the site. This does not set a target for each installation or sector, rather an overall cap of emissions for all participating industries which gradually reduces. Within the scheme the participants receive a proportion of allowances for free (where at risk of carbon leakage - the movement of production and emissions from one country to another due to different levels of decarbonisation effort through carbon pricing and climate regulation) and / or buy emissions allowances to cover the remainder of their emissions, thus the incentive to reduce emissions is through the carbon price and to achieve it in the most cost effective manner.

The roadmap highlights actions and investments to date that have resulted in an absolute reduction in CO2 emissions of 25% since 2005. For dolime, CO2 emissions from fuel combustion have reduced by 38% since 2005. The roadmap then illustrates the pathway to net negative emissions by 2040, across five key levers of recarbonation, fuel switching, carbon capture utilisation and storage (CCUS), indirect emissions (associated with the use of electricity) and transport.

It is important to note that to achieve the ambition of the roadmap will require key enabling regulatory action from the Government across finance, infrastructure, CO₂ accounting and the regulatory framework. There have been important recent supporting actions by the UK Government that are providing the foundations for the decarbonisation of British energy intensive industries including lime manufacture. The process is far from complete and the ability for the lime businesses to make their investment decisions to achieve the 2040 goal, needs certainty in the physical provision of the necessary infrastructure that enables the key levers of the roadmap.

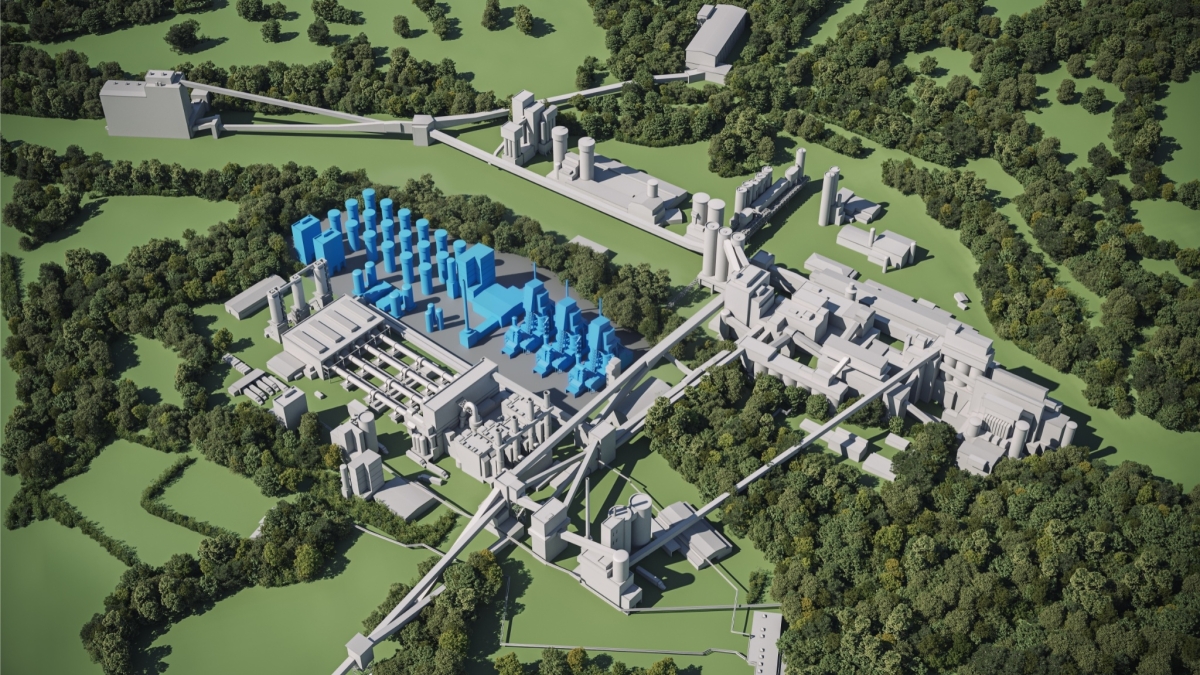

There are a wide range of research and development projects which the international businesses that own the lime producers in the UK, are involved in, that are driving towards the environmental pillar of sustainability. These include working with kiln manufacturers in developing new calcination kiln technologies, working with the emerging carbon capture and storage industry to address the unavoidable process emissions, working with the fuels and wastes sectors to enable replacement of fossil derived fuels used in lime production.

The direction of travel of UK Government policies is leading to the recent announcements in establishing CCUS, in production and transport of alternative fuels including hydrogen, as well as in decarbonised electricity generation. These are all tangible moves of key levers identified in the MPA Lime Net Negative Roadmap.

The future most important challenge, other than improving safety, is the overarching one of being a sustainable industry continuing to supply the essential mineral lime products that society relies on. An important further challenge is developing the ongoing decarbonised production of lime to help to address the climate challenge through application of technologies that can tackle the increase in carbon dioxide levels, and thus potentially reverse the trend and help restore the atmosphere to closer to it’s natural, pre-industrial, balance.