The Elevate IoT platform continuously monitors conveyor belts

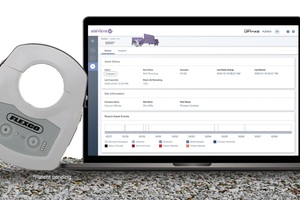

Flexco has developed the Elevate IoT platform – an intelligent Industry 4.0 solution that enables conveyor belt operators to monitor their belts in real time. Operators can access this easy-to-use platform that simplifies and accelerates maintenance using data-based decisions. It even prevents system downtimes by taking preventive action.

If conveyor belts fail unexpectedly in mines or cement plants, it can prove expensive for plant operators because all operations simply come to a standstill. All is not lost, however – Flexco’s Elevate provides the right solution to reduce and even avoid such downtimes thanks to its holistic monitoring system.

Until now, employees checked the on-site condition of the conveyor belts and their components, such as belt cleaners. If they could discover the problem, they waited for the service team – and spare parts. Valuable time passed before the system could be made operational again. This check often involved an inspection of the entire conveyor line, which was time-consuming and dangerous because the technicians sometimes had to squeeze into tight spaces to inspect the systems. However, Flexco Elevate now enables conveyor belt operators to act proactively instead of reactively, increasing their efficiency.

Collecting data, understanding the situation, deciding on measures

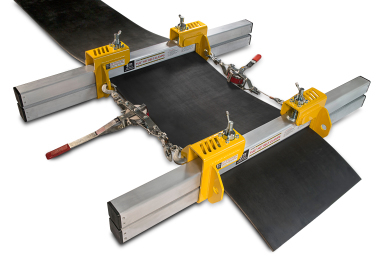

The platform data is obtained via Elevate devices attached to conveyor belt cleaners. The devices connect to the cloud via Wi-Fi or cellular at the push of a button, so cables are not required. When installing the devices on site, users can enter all the conveyor belt specifications on an app they can install on their mobile phones or tablets. Installation, commissioning, and monitoring procedures are fast and easy to handle.

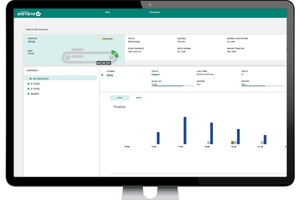

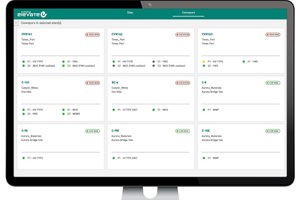

The app transfers all the data to the cloud, so the inputs can also be seen on the i3 dashboard. The responsible employee receives warnings and notifications via this digital dashboard with its intuitive operation: Have any malfunction signals occurred? What is the current position and wear of the conveyor belt cleaner? When should the next maintenance job be carried out? Technical data regarding the conveyor belt system or the running times of the belt and belt cleaners is also available.

Thanks to all this data, operators can make well-founded decisions in good time and decide on any measures that may be necessary. For example, in the event of a malfunction signal that involves a proactive belt inspection on site, operators can remedy problems at an early stage and not simply react after a severe malfunction has already occurred.

The performance of the belt cleaners and the condition of the conveyor belt can be assessed at any time and from anywhere, so there’s no need to send for service technicians. The Elevate system can also optimize maintenance work, so these tasks can be planned in more detail and carried out more efficiently. The system gives the operator an overview of all the essential data, enabling him to plan his resources much more efficiently.

The Elevate system starts collecting data and providing information immediately after it’s commissioned, increasing efficiency and added value from day one!