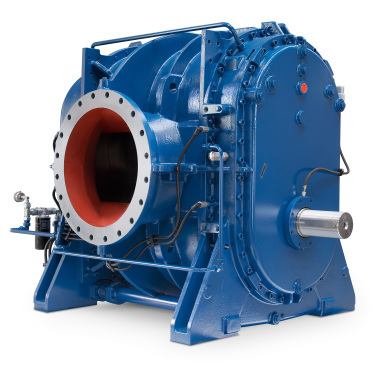

The new Delta Hybrid: Efficiency booster & Security fanatics

Pneumatic conveying systems for bulk materials, e.g. in the food industry, chemical and process engineering, cement and lime industry, and many others, have to reconcile a multitude of requirements – hygiene, explosion protection, robustness, product safety, efficiency, etc. – with one another. Home game for the new Delta Hybrid. The oil- and absorption material-free rotary lobe compressors with ATEX certification ensure the highest process air quality, comply with the ISO 22000 standard, are unrivalled in their reliability in operation and achieve enormous energy savings of up to 30% compared to a conventional positive displacement blower.

Aerzen rotary lobe compressors, also known as screw blowers, combine the advantages of blower and compressor technology in one system and stand for maximum energy efficiency, minimum life cycle costs, 100% pure and reliable process air as well as high durability even under extreme conditions – features that make the Delta Hybrid the ultimate for pneumatic conveying processes. With the current expansion of the portfolio, Aerzen is now taking the next step and raising the successful series to the next technology level.

The four new package sizes provide absolutely oil- and absorption material-free air and cover volume flows from approx. 2 to 30 m³/min as well as drive power from 7.5 to 55 kW. Thanks to an innovative compressor stage with new high-efficiency screw profiles, internal flow optimisation, paired with motors of energy efficiency class IE4 as standard, as well as optimised routing of the cooling and exhaust air, outstanding energy savings of up to 30% are achieved compared to a conventional positive displacement blower. The self-tensioning belt drive with an efficiency of over 98% also contributes to this, providing maximum flexibility in terms of volume flow and motor power.

The patented bearing enables a service life of 70000 h and more. An effective sealing concept for the drive shaft and the conveying chamber minimises natural wear and also guarantees freedom from oil in accordance with ISO 8573-1 PI class 0. The patented reactive silencer without absorption material successfully prevents contamination of the process air as well as the customer’s products. The rotors are uncoated so that no abrasion can enter the conveying air. These are decisive factors for sustainable, safe and long-lasting operation in pneumatic conveying systems for sensitive bulk materials. In addition, the new Delta Hybrids feature a reduced final compression temperature (up to 10 °C lower), enabling gentle transport of sensitive materials such as sugar or cocoa and milk powder. The rotary lobe compressors comply with the current ATEX product directive 2014/34/EU and can be used in highly critical, explosive working environments (e.g. flour dust) without any problems.

Highest energy efficiency, hygienic design, first-class product quality, reliable explosion protection: with the new Delta Hybrid, Aerzen defines a new benchmark in blower and compressor technology and offers the industry directional packages for the pneumatic conveying of sensitive, powdery and granular media. The result: safe, clean and reliable processes.