The role of the future: The new E-Prime Tracker 4.0

Anyone who has dealt intensively with the subject of belt misalignment on bulk material handling systems in the past knows the devastating effects. The multitude of solutions in the form of various belt guide rollers to remedy the misalignment problems is also well known. Most of these are conical in design and sometimes, after short-term effectiveness, have proven to be the opposite in the long run, even having destructive potential in individual cases. At present, people responsible will have already heard of the PrimeTracker. A special castor that detects belt misalignment and automatically compensates for it. This is why ScrapeTec Trading GmbH also positions its special roller as a “conveyor belt tracking assistant”.

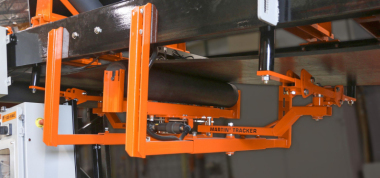

PrimeTracker principle: Cylindrical roller with skew correction

In contrast to many previous solutions, the PrimeTracker is not conical but cylindrical. This subtle difference ensures fast and automatic correction if the belt does not run centrally, but crooked. The PrimeTracker’s mode of operation is as simple as it is ingenious: it is mounted centrally on an axis and can therefore “swing” completely freely in any direction in order to react sensitively and directly to the slightest misalignment and, by correcting it, allow the conveyor belt to run optimally again. If everything is in order and the belt is running straight, the PrimeTracker simply acts as an idler. Conical variants cannot do this. Thanks to these properties, ScrapeTec Trading GmbH can report a growing demand for the “Regulator”. This is because perfect belt guidance is essential, especially at transfer points on conveyor systems, to ensure that the seals work optimally and to prevent dust as well as spillage. This applies in particular to the AirScrape, the non-contact side seal from ScrapeTec. Its mode of action is only given at an optimum distance from the belt. The result is almost 0% dust and material loss. Whether cement plants, mining companies or food logistics companies - more and more companies worldwide have discovered ScrapeTec dust protection solutions for themselves. PrimeTracker is just one of them.

The next generation: E-PrimeTracker with sensor technology

ScrapeTec is now offering a further development for the future, which also means the future of industry in general: the E-PrimeTracker 4.0. Its self-regulating function on conveyor belts corresponds 1:1 to that of the PrimeTracker. The E stands for the electronic added value of this device, which ScrapeTec’s developers have integrated. This is because the roller is additionally equipped with robust sensors that record all relevant characteristic values such as belt position, belt speed or the condition of the belt splice and make them available for monitoring.

The advantage: If misalignment situations occur that could lead to a possible belt standstill, the operator is warned in good time and can take precautionary action. And even the worst case scenario, such as a misalignment scenario with belt lesions and impending belt breakage, is indicated in good time. On the one hand, this warning is given via a color display on the device, which shows the belt running situation from green to red. On the other hand, the information from the sensors can also be transmitted wirelessly to a monitoring system in which the control data is displayed. This is entirely in line with the idea of Industry 4.0, in which the aim is increasingly to digitize processes, thus making forward-looking measures such as condition monitoring and predictive maintenance possible. It also corresponds to the trend in the area of conveyor systems to leave the “archaic” path of tolerating robustness with dust, dirt and material losses and instead implement solutions that sustainably protect people, the environment and technology.

World premiere: The E-PrimeTracker at bauma 2022

ScrapeTec will present the E-PrimeTracker for the first time at bauma in Munich. Wilfried Dünnwald, owner of ScrapeTec and developer, is responsible for the presented further development of the PrimeTracker and will present the functionality first-hand at the trade fair.