Titan Cement Group launches CemAI

Titan Cement Group has launched CemAI, Inc. (CemAI), an affiliate company providing the next generation predictive maintenance solution based on Artificial Intelligence for the cement industry.

The solution is a unique mix of a proprietary licensed software and a continuous monitoring and incident resolution service for entire cement manufacturing lines across the world. Leveraging on the unique manufacturing experience and digital expertise of Titan, which has created, successfully tested and already installed the CemAI solution at several of its locations around the world, the solution will help cement companies maximize the operational efficiency and reliability of their plants while making their processes more efficient and cost effective.

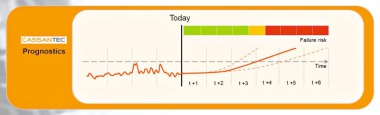

CemAI’s solution complements the expertise of local plant maintenance teams by adding the dimension of predictive analytics, bringing cement plant maintenance into the digital age of AI. It leverages machine learning technology that processes in real-time the operating data of entire cement plants, generating alerts that are analyzed by a team of experts with years of experience in cement operations, working in close collaboration with plant’s operational teams, to resolve issues before they affect operations. CemAI works through remote monitoring centers that collect and analyze the data stream from plant sensors, 24/7.