The new PFEIFFER roller mill MVR: reliable grinding technology for high throughput rates

Summary: In the cement industry, the trend is towards ever increasing grinding capacities of individual grinding plants. As a result, plant availability and optimized maintenance concepts are becoming more and more important. The newly developed MVR roller mill from Gebr. Pfeiffer AG for grinding cement raw material, cement clinker, and additives with an installed power of up to 12 000 kW does in fact fulfill these customer requirements perfectly. The modular design of the MVR mill comprising 4 to 6 grinding rollers allows the continuation of mill operation even if one roller module is not available. The same applies to the new MultiDrive® design of the mill drive consisting of up to 6 identical drive units in the range of 2000 kW each. So mill operation may continue while maintenance work is being performed on a drive unit. Hence any unplanned downtimes are considerably reduced even in the case of an outage of the main components.

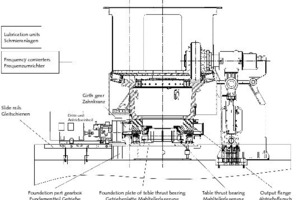

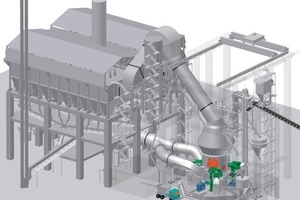

The newly developed MVR mill has the following main components (Fig.1):

– 4 to 6 grinding rollers with cylindrical wear part geometry

– flat grinding table, with its outer diameter in mm appearing in the name of the mill

– housing for gas conveying, with nozzle ring and classifier

– new modular drive unit “MultiDrive®” or alternatively conventional drive with planetary gear

A roller module consists of the roller with cylindrical roller tire, roller axle, roller arm, bearing stand, and transmission of hydraulic force. Due to this type of roller suspension in...