Gebr. Pfeiffer to supply the world’s largest vertical roller mill for cement

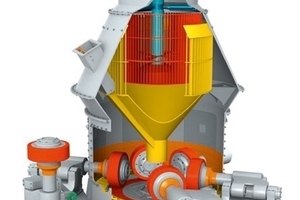

Holcim (Brasil) S.A. has awarded the Spanish EPC leader Cemengal a contract to supply a state-of-the-art cement grinding station to increase the capacity of its Barroso works located in the Brazilian state of Minas Gerais. Acting as main contractor for this grinding project, Cemengal ordered an MVR 6700 C-6 roller mill from Gebr. Pfeiffer SE which with its production capacity of up to 450 t/h

of cement will be the world’s largest cement mill. The mill will be grinding various blended cement qualities with clinker portions of up to 90 % and slag portions of up to 65 % to product fineness degrees of 4000–4800 cm2/g acc. to Blaine. A MultiDrive® with 6 single drives, each of

1920 kW, will be used to drive this mill. This innovative drive concept will have an available total drive power of 11 500 kW. This amount of power cannot be implemented with conventional drive systems for vertical roller mills. The individual drives will be synchronized by frequency converters which will also allow the speed to be adapted to the various product qualities.

During the technical development of the MVR mill Gebr. Pfeiffer SE placed special emphasis on plant availability and ease of maintenance. As a result, the new mill concept allows individual grinding rollers to be swung out from the mill for maintenance works, for example to replace the wear parts, without the need to interrupt operation for a prolonged time. After one roller has been swung out, the mill can continue to operate. In the case of the mill for Holcim (Brasil) S.A., the nominal grinding capacity available will still be significantly more than 80 %. Comparatively, the 2-mill concept, an alternative for this capacity, would involve substantially higher total investment costs and the outage of one grinding roller would cause the grinding capacity to reduce by half due to the lack of active redundancy. Similarly to the grinding rollers, the MultiDrive® is also actively redundant where each of its 6 drive modules can be disengaged and the mill can continue in operation.

Many years’ operating experience of vertical mill operators has been incorporated into the overall MVR concept with MultiDrive® (Fig.). At this point special mention is to be given to Holcim who not only ordered the first MultiDrive® for a vertical roller mill in 2008 but also actively accompanied the technical detailed implementation through Holcim Group Support/Switzerland. Apart from the complete vertical roller mill, this deal will see Gebr. Pfeiffer SE supply a hot gas generator, which is intended to provide the heat when materials of high moisture content are ground and/or clinker cooler exhaust gases are not available. Cemengal as main contractor for this EP project will be in charge of the design and supply of all mechanical, electrical and process control equipment, except for the VRM. Moreover, Cemengal’s scope will include steel structures and process design as well as erection supervision and commissioning. Overall planning will be done by Cemengal in close co-operation with Gebr. Pfeiffer SE and the customer.

The mill concept MVR with MultiDrive® is a revolutionary advance in the area of vertical mill technology thanks to the active redundancy of the rollers and the drive modules. Active redundancy allows even the largest units to obtain levels of availability that have so far been unachieved. This innovation enables, for the first time ever, large cement facilities to be designed with the one-mill concept for both raw meal and cement grinding. The mill planned to be commissioned at Holcim (Brasil) S.A. in 2013 will mark another milestone in Gebr. Pfeiffer’s 150-year history. With this new order, Cemengal as main contractor and Gebr. Pfeiffer SE as supplier of the most advanced VRM technology have formed an alliance, consolidating their forces to be prepared for future challenges worldwide.

www.gpse.de