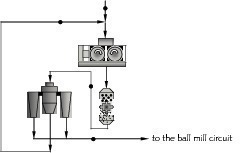

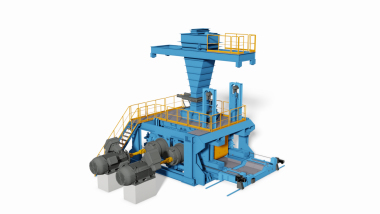

Circuit high pressure grinding rolls (HPGR)

in a cement grinding plant

Part 2: Effect of operating parameters

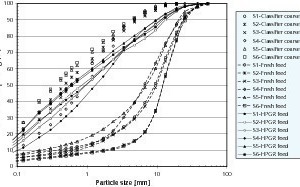

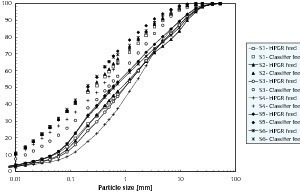

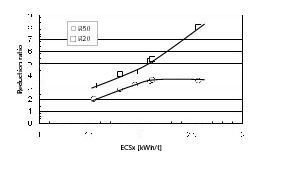

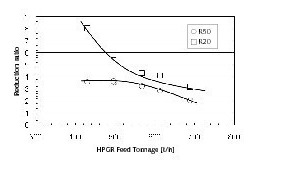

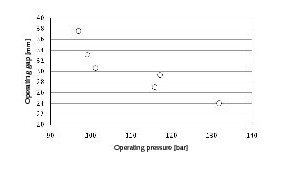

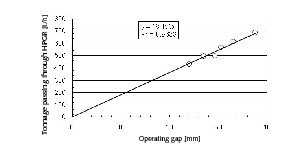

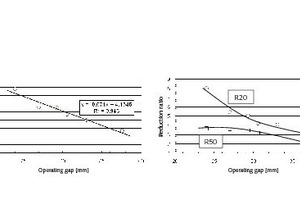

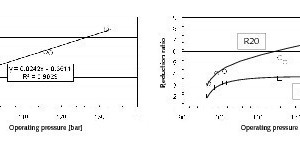

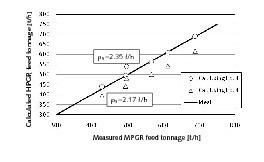

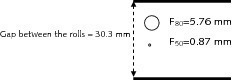

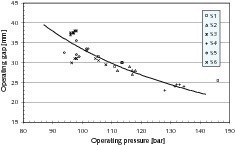

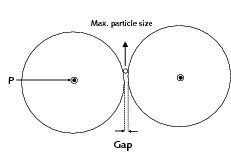

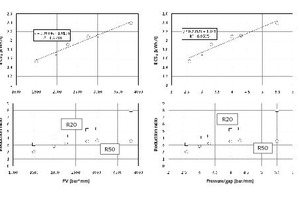

Summary: This paper presents the effect of operational parameters on the performance of a closed circuit HPGR. For this study, six surveys in a cement grinding circuit operating in Turkey were performed. The relationships among operational parameters like gap, pressure and capacity and the effect of these parameters on the performance were investigated. A new operational parameter, PX, representing work done on the particle bed and the effect of this parameter on the performance were presented. The results indicated that linear relationships can be established between specific energy consumption (ECSx, based on HPGR feed tonnage) and gap, pressure and PX parameters. The best correlation is obtained at the relation between PX-ECSx.

Effects of operating parameters have been investigated by various researchers mostly through laboratory and pilot scale data ([1], [2] and [3]). Models have also been developed to describe the process.

Despite advances in technology and applications, relatively few data have been published from operating plants. In the cement industry, it was shown that the more would be gained when a larger amount of size reduction work is performed by HPGR [4]. In closed circuit applications, the performance of the air classifier is also affected by the operating variables [5].

In this study,...