Quality improvement of β-plasters

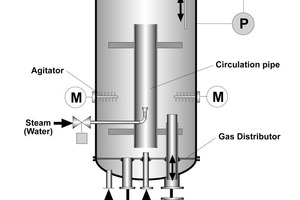

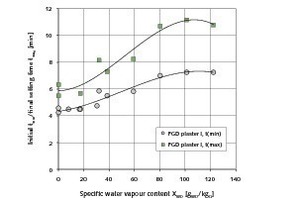

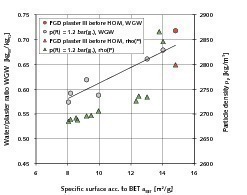

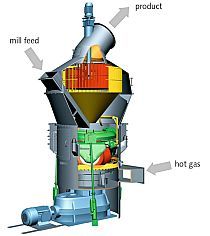

Summary: This article presents a new post treatment process for improving the quality of β-plasters. The treatment process involves controlled water vapour treatment of gypsum supplied from an upstream calciner system in a continuous-operation fluidized bed reactor with forced internal recirculation. For the treatment process, a partial flow of the exhaust gas with high water vapour content from the calcining process is used as the fluidizing and recirculating gas, but gas from another available source or separately generated steam injected into the circulation pipe can also be employed. The two variants can also be combined. After an introductory fundamental consideration, the process – which can be intensified by increasing the reactor pressure – and the associated hardware are presented and discussed on the basis of the results achieved in systematic trials.

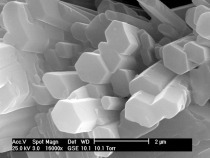

The binding agent calcium sulfate, consisting of the phases hemihydrate = CaSO4 · ½ H2O, anhydrite III and II = CaSO4, pure or in various mixtures, is produced by thermal dehydration from raw gypsum, e.g. natural gypsum, gypsum from flue gas desulphurisation (FGD) or phosphogypsum = dihydrate CaSO4 · 2H2O including impurities. The essential constituent is generally the hemihydrate. This and the anhydrite derived from it occur in an α- or β ‑modification depending on the selected manufacturing conditions. The two hemihydrates have the same crystalline structure but different...