Feasibility study – Recycled gypsum for gypsum plaster and the use of cellulose ether

Recycled gypsum as a raw material for mortars such as gypsum plaster is hindered by significant prejudice and is not well accepted in the industry. Gypsum plaster with partial replacement by recycled gypsum also demonstrates that sustainability of construction materials is possible and represents another positive step toward circularity in construction.

1 Introduction

Recycled gypsum (RC Gypsum) as a raw material for gypsum board production is well accepted in the construction industry. However, it’s use as a raw material for mortars such as gypsum spray plaster (GSP) is hindered by significant prejudice and is not well accepted in the industry. Due to impurities (solid and chemical) and variation in quality of RC Gypsum, the overall application performance (e.g. workability, leveling, etc.) can change significantly. The objective of this study is to identify whether RC gypsum as a raw material for gypsum plaster is feasible. This publication is a summary of the first lab investigation with RC gypsum for mortar application. To improve mortar workability, it is important to carefully select modification agents like cellulose ethers (CE). Specially designed hydroxyethyl methylcellulose (HEMC) offers an optimized powder dissolution time to help avoid lump formation [1]. CE addition significantly improves water retention and workability performance (mortar rheology) of a GSP. The importance of consistency building upon mixing dry material and water often remains unconsidered. The application data proved that modified CE, with an optimized morphology, fits best to improve the application performance of GSP containing RC gypsum. RC Gypsum will offer a suitable alternative to commonly used Flue-Gas-Desulfurization (FGD) gypsum as production of FGD slows due to regulatory changes throughout Europe.

Different types of gypsum sources can be used for mortar application: Natural, synthetic and Flue-Gas-Desulfurization (FGD) gypsum.

The availability of FGD gypsum is expected to drastically decline in the next several years (Figure 1)

mainly due to the energy revolution, and the national climate protection plan (exit from coal-fired power stations) in Germany and other European countries.

Against this background, the gypsum industry is looking for new gypsum resources to cover their demand. The use of RC gypsum for mortar application is not available at this time. Gypsum waste primarily consists of waste from gypsum boards.

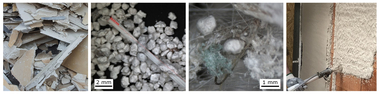

Depending on their origin three main types of gypsum waste can be distinguished:

Gypsum waste from the manufacturing of gypsum products: This type of gypsum waste consists of rejects and non-spec material. Its recycling is usually part of the waste avoidance activity of the gypsum board plants

Gypsum waste from new construction: This typically clean waste mainly consists of plasterboard off-cuts resulting from cuting boards to fit the dimensions of a certain wall or ceiling. The waste may constitute around 15 % of gypsum material installed on site. It is generally referred to as new construction gypsum waste and can be reduced by ordering boards “made-to-measure”. However in most markets such tailored boards represent less than 10 % of all orders

Gypsum waste from demolition and reconstruction: This waste arises during demolition, refurbishment or renovation of building structures when plasterboards which usually were installed years before have to be removed. For this reason some refer to it as “old gypsum waste” whereas the trade usually refers to this waste as “demolition waste”

Different from the first two types of gypsum waste described above, this gypsum waste from demolition and reconstruction is more likely to show a certain degree of contamination.

RC gypsum as a raw material for gypsum board production is well accepted in the construction industry. However, RC gypsum from demolition and reconstruction as a raw material for mortars such as gypsum plaster is not accepted in the industry. This is caused by impurities (both solid particles and chemical impurities) as well as by variation in quality of the recycled gypsum. Both factors can impact the overall application performance (e.g. workability, leveling, etc.). Workability of gypsum plaster however is a key application feature for the effectiveness of any craftsmen.

There are many different drivers not to use RC gypsum:

Economical: Depositing waste is currently cheaper than recycling [3]

Availability: Product availability cannot close the demand gap of current FGD gypsum demand

Aesthetics: Lack of acceptance for indoor application due to undesirable features (smell, VOCs)

Quality: RC gypsum could contain high amounts of fibers (commonly occurring when demolition companies deliver unsorted gypsum waste)

The joint feasability study with German gypsum plaster producer Casea GmbH (part of the Remondis Group) could however demonstrate that this specific RC gypsum can be used for spray plaster in combination with the right chemistry.

2 Raw materials and formulations

2.1 Recycled gypsum

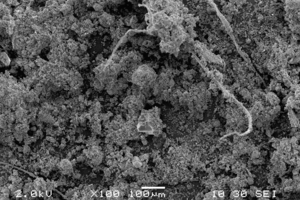

Quality requirements for RC gypsum are defined by the German Gypsum Association [4] (BV Gips). Key test criteria are needed for gypsum purity, the type of impurities (fibres, plastic), the moisture, color and odor. In addition to the visible impurities like fibers, there are “chemcial” impurities such as hydrophobic additives, plasticizers or foaming agents, which can have a negative influence on the overall end properties of the gypsum.

2.2 Characterization of gypsum raw material

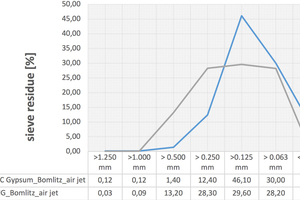

Figure 2 shows the air sieve analysis of a natural (multiphase) gypsum plaster and plaster made from RC gypsum (hereafter recycled plaster).

The recycled plaster is finer (different morphology) with some visual impurities such as long fibers (Table 3). The difference in color, odor and pH value is negligible. The recycled plaster shows a more “fluffy” powder behavior and therefore also had lower powder density (0.62 g/ml) compared to the natural gypsum plaster (0.94 g/ml).

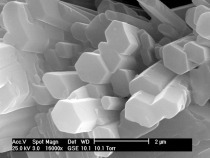

The multiphase plaster was produced within an existing production line with a GPAG EM Mill including a high temperture phase. So the plaster contains Beta-hemihydrate and Anhydrite AIIs [5]. Compared to this the recycled plaster is pure beta-hemihydrate made by a laboratory rotary kiln without a high temperture phase, so without Anhydrite AIIs. The calcium sulphate content of the raw gypsum materials used are nearly equal with around 83-85 %.

The result of the phase analysis of the recycled plaster is significantly different in comparison to the natural gypsum (Table 1). The RC gypsum does not contain any Anhydrite II phase (A II), and this has a significant impact on the speed of crystallization during the hydration process. Crystallization is too slow, so that crack formation will occur. The recycled plaster contains more carbonate which is used as filler for the production of gypsum boards. Another important difference is the water demand of the recycled plaster. The recycled plaster is characterized by a significantly higher water demand (lower interspersion quantity (101 g/100 ml vs. 149 g/100 ml). Due to the high water demand, the strength development and hardness of the hydrated gypsum is negatively affected.

Table 1 and Table 2 summarize the analysis and some key application properties such as setting and strength development provided by Casea, Germany.

2.3 Cellulose ethers

Cellulose Ethers (CE) impart water retention properties that limit loss of water from the plaster to absorbing substrates allowing for a steady setting and high final strength. Additionally, the very specific rheological profile of CEs improve spray application and significantly ease subsequent leveling and finishing steps. In spite of these clear advantages, the use of CEs in gypsum-based plaster has drawbacks - they are known to potentially lead to the formation of dry agglomerates when working with spray machines. This formation of non-wetted agglomerates, also called lumps, negatively impacts leveling and smoothing of the plaster. Newly designed hydroxyethyl methylcellulose (HEMC) offers an optimized powder dissolution time (which relates to the CE morphology) and helps avoid gypsum lump formation. The characterization of the CEs used are reflected in Table 4.

2.4 Gypsum spray plaster formulation

Lab investigations were done with raw materials such as RC gypsum, multiphase gypsum, perlites, etc. provided by Casea GmbH, Germany. For the lab study different formulations have been used (Table 5).

3 Lab assessment/Application data

Table 6 summarizes the lab data of formulation # 1-3 with different gypsum quality ratios.

Thickening was tested via slump test. Results in Table 6 show thickening performance is significantly weaker when pure NG gypsum is used. With the use of RC gypsum, water demand significantly increased. Caused by the higher water demand and lower wet mortar density (Table 8), the flexural and compressive strength is lower. Despite a higher water demand, the water retention of formulation #2 and #3 (containing recycled gypsum) is slightly higher.

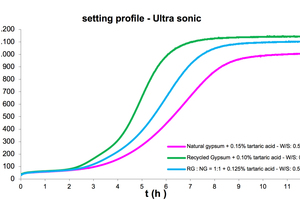

Setting of gypsum products is important and adjusted to application needs by dosing setting retarders (e.g. organic acids such as tartaric acid or citric acid). Due to the setting behavior of the different gypsum qualities and blend ratios, the set retarder (tartaric acid) was adjusted to reach similar start and end setting times.

The setting behavior measured with Vicat shows that by using the right amount of setting retarder, the setting times can be well adjusted. However, Vicat shows only the first three hours of gypsum plaster setting and does not display the post-setting stage (hardening process). The post-setting behavior can be measured with ultrasound and the results shows that recycled plaster still has a non-optimized crystallization process, which caused crack formation (Table 8 – spray plaster trial) (Figure 4).

The formulation (Table 8) containing RC gypsum showed extreme crack formation only a few minutes after applying on the wall. As a crack formation might occur in gypsum plaster with a non-adjusted dehydration process, the hypothesis was to accelerate the crystallization process by adding calcium sulfate dihydrate (CSD) and therefore prevent shrinkage and crack formation.

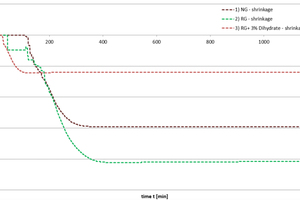

To determine the shrinkage of fresh as well as hardened mortar instantly, a modified shrinkage drain in accordance to EN ISO 6873 (Dentistry – Gypsum products) was used.

Beside the two samples with 100 % RC and 100 % NG, the sample setup contained an accelerated plaster with 97 % RG 3 % CSD (Table 7).

The results of the lab shrinkage experiment are given in Table 7. It is shown that the crack formation (seen in the plaster trial) can be correlated to the shrinkage in the lab. RC gypsum formulation shows significantly higher shrinkage than NG. The shrinkage can be radically reduced with the addition of 3 % CSD (a well known accelerator in the gypsum industry).

The sample containing RC gypsum with 3 % CSD (as an accelerator) shows a faster setting development with decreased shrinkage compared to the samples with 100 % NG and 100 % RC gypsum (Figure 5). The reduction of shrinkage results in reducing the crack formation of the plaster. The optimal dosage of CSD in RC gypsum still has to be found for this formulation with regard to application characteristics.

3.1 Application spray trials

Generic gypsum plaster formulation was used for the application spray trial. All tests were run with a PFT G4 spray machine equipped with a short hose (13 m). A short hose helps to reveal wetting or dissolution issues upon mixing, which are not visible with long hoses, respectively residence time.

In the spray laboratory, water demand, hose pressure (at the spray machine) and consistency of the wet mortar were measured. Beyond this, application “feel” on the wall is crucial for evaluation. For mixing/spraying, splattering and tack (material needs to adhere to the wall upon spraying) is taken into account. For leveling/workability, the ease of application, shear stability, standing strength and stickiness is rated. Paring and felting is characterized by peeling, workability and the mass of smooth finish. The smoothing/finishing step (done 140-150 minutes after application) in gypsum application is rated for mass of smooth finish and workability as well.

CE reference was a modified WALOCEL™ Xtra Cellulose Ether with an addition rate of 0.208 %. Lightweight bricks (high water up-take) were used as a critical substrate for the assessment of the different CEs. As seen in Table 6, formulations containing RC gypsum have a lower water demand under practical conditions (same consistency), and a lower mortar density, but the material is fluffier. Formulations containing RC gypsum are characterized by a different odor in comparison to the natural gypsum. The fresh mortar odor is like “wet wallpaper”. Small portions of RC gypsum in a formulation will not be noticeable.

Three results are to be highlighted:

1. First even-out/leveling: Formulations containing RC gypsum and modified Walocel Xtra HEMC impart a better standing strength and significantly better sliding in comparison to the reference (natural gypsum/modified Walocel Xtra HEMC).

2. Paring/second leveling: Formulations containing RC gypsum and modified Walocel Xtra HEMC impart a less sticky mortar and again, significantly better sliding in comparison to the reference (natural gypsum/modified Walocel Xtra HEMC)

3. Crack formation: Formulations containing RC gypsum as a binder develop a multiplicity of cracks. This is caused by the phase configuration of the binder. The dehydration process must be adjusted so that multiphase gypsum develops or gypsum dihydrate must be used as a strong accelerator (see lab assessment). Both alternatives are state of the art in gypsum industry.

Due to these good application results, RC gypsum can be used in spray plaster with the same cellulose ether grade.

4 Conclusion

The use of RC gypsum as a binder in gypsum plaster is feasible without negative impact on workability of the gypsum mortar at job sites. RC gypsum opens up the opportunity to replace FDG gypsum in plaster formulations, which will be less available in the European market due to the energy transition over the coming years Sustainable solutions for these types of challenges are the prerequisite for successful product innovation.

Durability is at the heart of circularity when it comes to construction. Gypsum plaster with partial replacement by RC gypsum demonstrates how to design products and systems based on natural concepts and materials in an effort to reduce raw material extraction and depletion, prevent landfill material waste, use recycled waste and reuse material.

Additionally, selecting a cellulose ether with optimized particle morphology for low lump formation fits best as a thickening agent to improve application performance of gypsum spray plaster, even if the gypsum base contains RC gypsum.

https://de.dow.com | //www.casea-gips.de" target="_blank" >www.casea-gips.de:www.casea-gips.de

![1 Three pillars of raw material supply and future needs [2]](https://www.zkg.de/imgs/1/5/3/9/6/7/6/tok_54ad0fdd15ea0e9561274242d31bfd4f/w300_h200_x600_y366_Materials_Dow_Figure_1_updated-6949419de1374d3a.jpeg)