The first part of the article in issue 5/2012 dealt with the basics and case study I. It was shown, how MI-CFD modelling can be used to understand the thermo-fluid dynamics of a calciner. In Part II a second case study and suggestions for the utilization of AFR are presented.

Case study II

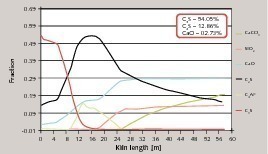

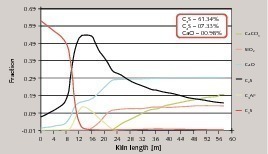

The second case study is selected from a natural gas fired plant operating at 40 % heat input in the kiln burner and 60 % in the calciner. The client wanted to replace natural gas by waste derived fuels, i.e., Solid Recovered Fuel (SRF) and biosolids in both calciner and kiln burners. A brief summary of the...

TEXT Dr. Tahir Abbas, Tom Lowes, Cinar Ltd., London/UK

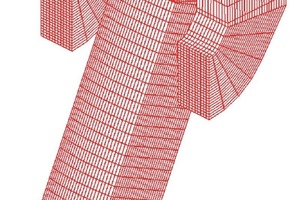

![3 Illustration of air-through precalciner riser duct [dimensions in mm]](https://www.zkg.de/imgs/tok_5a533e48c55d38702fe32207cd2c3b8e/w300_h200_x400_y457_101531240_29637e99db.jpg)

![10 Oxygen concentration [kg/kg] (cut off at 6 % O2)](https://www.zkg.de/imgs/tok_7fb528cfecd12ebd50fbffedf48cf7ed/w300_h200_x400_y400_101531239_645395691d.jpg)

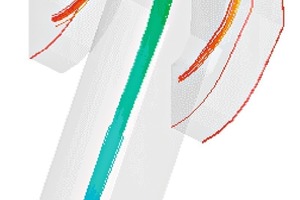

![11 Temperature distribution inside the precalciner riser duct chamber [in C°]](https://www.zkg.de/imgs/tok_e0f6fcc794973d28e95a52075d391875/w300_h200_x400_y400_101531272_6e399ef24f.jpg)

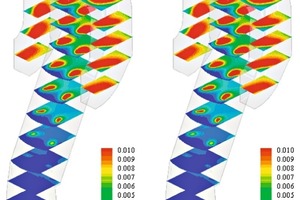

![13 Petcoke particles’ residence time in the riser duct (a = Base case, b = extended riser duct with lower burner location) [in sec.]](https://www.zkg.de/imgs/tok_e9280f61905551fe6f03de1c3faecd6a/w300_h200_x400_y375_101531187_7672328416.jpg)

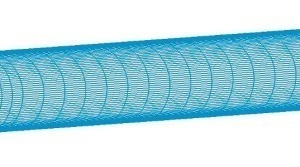

![1 Kiln hood, kiln burner and kiln layout [dimensions in mm]](https://www.zkg.de/imgs/tok_ca6887baad017751a58d8bd550e704ac/w300_h197_x400_y98_101531249_202a535c89.jpg)

![4 Temperature profile [in °C] (Temperature at oven exit = 1077°C)](https://www.zkg.de/imgs/tok_90926715b671072a528aa2b5a92cbe50/w300_h200_x400_y195_101531203_bbd1208b14.jpg)

![5 Oxygen concentrations [in mass %] (O2 concentration at oven exit = 5,75%)](https://www.zkg.de/imgs/tok_371c1889eee9e73f02d5d908ad9a204e/w300_h200_x400_y148_101531226_42f87cf404.jpg)

![6 Velocity vector field with magnitude [in m/s]](https://www.zkg.de/imgs/tok_9861a996685277a7bec5677d653febb9/w300_h200_x400_y204_101531220_6586e8feba.jpg)

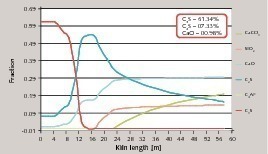

![7 Kiln bed temperature along the kiln length [in °C/m]](https://www.zkg.de/imgs/tok_176cd7bae7781553c2f344acff02d3fa/w268_h154_x134_y77_101531293_d979615c81.jpg)