Reduced energy consumption and smooth kiln operation

In 2009 Fauji Cement built a second kiln line to expand its production capacity and invested in a raw material proportioning (RMP) solution in combination with a SpectraFlow online analyzer to optimize its stockpile blending. The expanded operation increases the turnover at the stockpile from which both kiln lines are fed with raw material. The combination of pre-blending and raw mix proportioning software together with the SpectraFlow online analyzer resulted in a significant reduction of additives by providing raw meal with the correct kiln feed quality. Up to 98 % of the raw meal now comes directly from the stockpile.

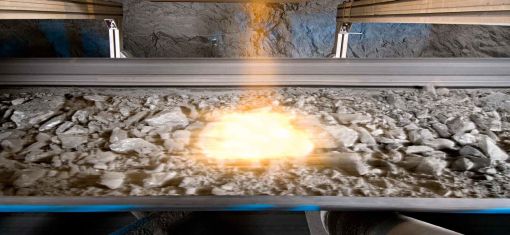

ABB’s SpectraFlow analyzer uses the SOLBASTM technology, which is an innovative application of the well-known and environmentally friendly Near Infrared (NIR) [1, 2]. The NIR ranges from 700 to 2500 nm which allow the use of standard lights as the analyzer’s source. ABB employs its long-established Fourier Transform Infra-Red (FTIR) spectrometer concept to obtain the final spectra. This ensures a high stability and repeatability of the analysis and enables the exchange of calibrations between spectrometers.

Previously, ABB also revamped Fauji Cement’s existing line, which feeds 3700 t/d, by delivering a 132 KV grid, an MV distribution system, a motor control center (MCC) including panels, motors and drives. In addition, ABB supplied a plant control system, a pre-mix and raw mill quality control system as well as an expert control system for the kiln, cooler, raw mill and the cement mill. This is ABB’s first order for the complete electrification of a cement plant in Pakistan. Many large infrastructure projects are helping to improve the socio-economic situation in Pakistan and turning the region into a growing market for cement.