Fans for the cement industry

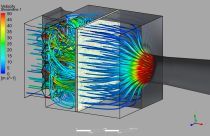

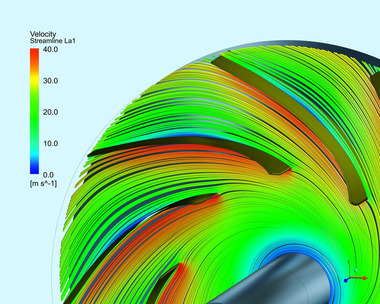

are extremely important to Venti Oelde with a permanent place in our product portfolio. The particular challenges of the cement industry have for decades stimulated us to achieve our best performances. Continuous improvement and investment in our production location in Oelde/Germany ensure that we meet the ever more demanding expectations. We are currently optimizing the efficiency of our fans to provide greater energy savings for our customers. Furthermore, we are testing new wear protection systems which promise longer service life.