Huge savings for the cement industry

Venti Oelde predicts longer useful lives and reduced time and effort for maintenance with their wear protection for process fans. Now the company is promising optimized systems.

In Germany alone wear annually causes damage amounting to billions of Euros. Process fans in the cement and non-metallic mineral processing industries are exposed to extremely tough conditions and, therefore, to massive wear. This is, in the main, abrasive wear. Venti Oelde possesses experience, gathered over decades, in the design and construction of industrial fans and is a technological leader in wear protection. The company constantly promotes research and development in this sector. Together with a reputable German technical university Venti has now meticulously examined wear on industrial fans.

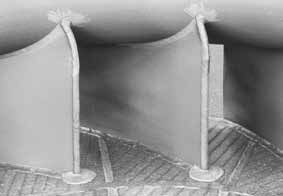

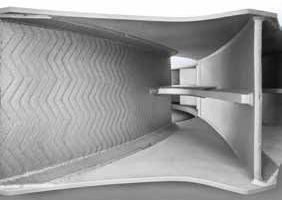

Complex blasting tests were undertaken using a variety of settings. The properties of different process dusts, known to cause wear, and samples taken from wear protection materials, among which were new materials, were analyzed. A large number of geometric arrangements of the wear protection layers were examined as well as new procedures for the creation of these layers. The systems used today were tested and compared under identical conditions. The promising new wear protection systems which were the result are already being tested in service.

In the cement industry it is impossible to avoid dealing with the subject of wear protection. Regular technical overhauls and maintenance proceduresare always essential when inadmissible vibrations occur or the flow volume and pressure specified for the production process are no longer attained.

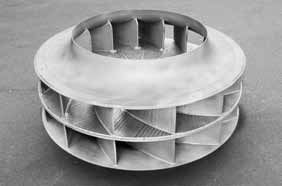

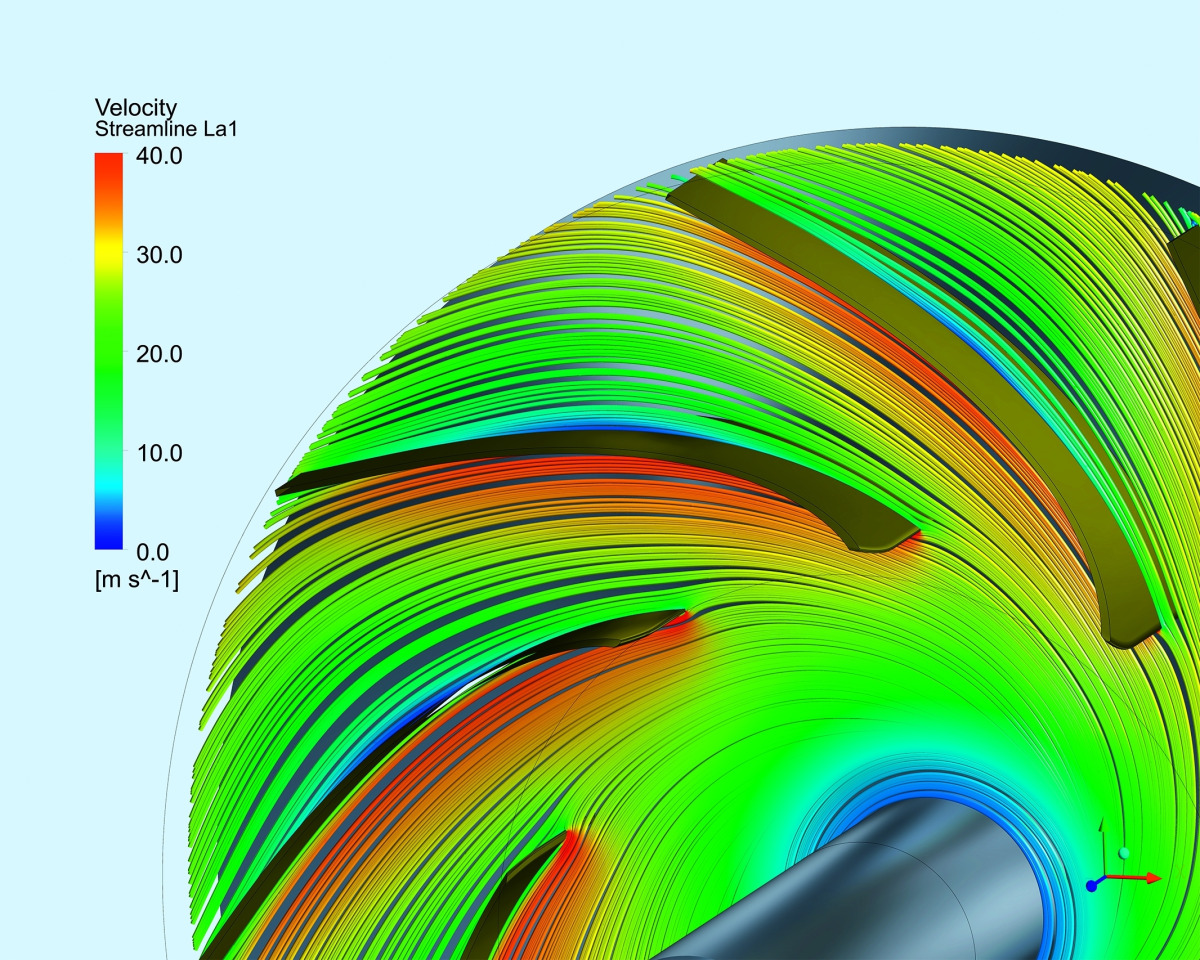

Wear has increased considerably during recent years. The principal reasons for this are process optimization and new and finer types of cement. The increased use of secondary fuels can also have a clearly adverse effect on the abrasive properties of the dust. Wear is caused by particles carried in the air-stream. The particles which enter strike all the structural elements of the fan – the impeller blades and the casing as well as the impeller shroud and impeller backplate. This attack can cause considerable wear damage.

Abrasion can lead to a decrease in performance or produce unbalance, preventing continued operation. Otherwise, irreversible subsequent damage may be the result. Even if a plant is shut down for a short time, the operator will suffer considerable losses. A suitable wear protection is, therefore, of primary importance.

The statement “The more, the better” can only be applied to wear protection with reservations. The essential thing is to take the correct measures. Using harder hardfacing does not necessarily provide the required result, especially as it is usually considerably more expensive and more complicated to apply. Furthermore, wear protection materials such as fused tungsten carbide are becoming more and more difficult to obtain and their price on the world markets is continuously climbing.

Venti Oelde’s approach is to select a wear protection system appropriate to the process. A parameter for the selection of the best wear protection is the composition of the dust in the air-stream causing the wear. In this process, as well as quantity and hardness, the particle size distribution andparticle geometry of the dust play an important part.

For example, when the dust is very fine and abrasive a wear protection system where the carbides are evenly distributed and as close together as possible must be selected. This prevents too great an erosion of the carbides. The structure of a wear protection layer generally consists of hard carbide grains cemented into a binder matrix.

If the so-called pitch, i.e. the distance between the carbides, is too great, the dust particles directly hit the soft binder matrix; this is then worn away relatively quickly and can no longer bind the carbides. As a consequence the carbides are eroded and break away from the matrix. Any advantage provided by the hard and tough carbides is then negated. The service life of the wear protection layer is comparatively short.

On the other hand, if the pitch is smaller than the diameter of the dust particles, the dust particles are more likely to come into contact with the hard carbides, and the softer matrix is protected. Use is made of the toughness of the carbides. Service life is clearly increased.

In the matter of wear protection Venti Oelde relies on individual optimization and offers efficient solutions even for difficult dusts with extremely high wearing properties. Maintenance is simplified and fan impeller repairs are usually still possible with the impeller in place. The result is a considerably longer service life and much lower repair costs. At the same time the risk of production loss is reduced to a minimum.