A TEC will install Flash Dryer

for alternative fuels at

Lafarge Zementwerke GmbH Mannersdorf

To reduce the moisture content of the alternative fuel (RDF) for the kiln burner, Lafarge Zementwerke GmbH Mannersdorf awarded A TEC a contract for the implementation of its innovative Flash Dryer. A TEC has already been nominated earlier with the engineering and supply of key equipment separately and now for the supply of all structural steel, residual ductwork and the mechanical erection works.

The project will be realized by the end of quarter one, 2021. The plant Mannersdorf of Lafarge Zementwerke GmbH is one of the leading manufacturers of high-quality cement in Austria, moreover it is one of Austria’s largest cement plants with a yearly capacity of 1.1 million t of cement.

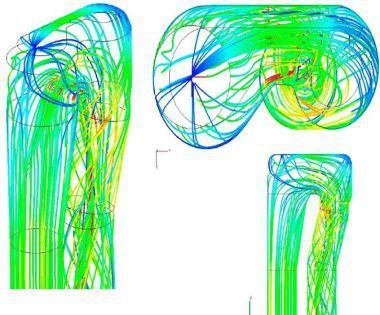

Flash Dryer for alternative fuels

Reaching high thermal substitution rates (TSR) requires firing of alternative fuels at the kiln burner. To reach a stable sintering zone for the required clinker quality a high fuel quality (high LCV, small particle size) is needed, otherwise the clinker quality may suffer or the TSR can be limited. With the A TEC Flash Dryer various waste heat sources can be used (clinker cooler flue gas, bypass gas, preheater gas, etc.). The material is dosed to the hot gas flow in the flash dryer and transported with this gas flow, while the moisture is evaporated, to a cyclone and a subsequent filter where the fuel is separated from the gas flow and on-line fed to a kiln burner or a satellite burner. In addition to the drying, the lifting effect of the gas can separate 3D impurities which contributes in a further increase of the fuel quality.