A method for reducing combustion

temperature and thermal radiation within a lime kiln

(22) 05.04.2021

(43) 07.10.2021

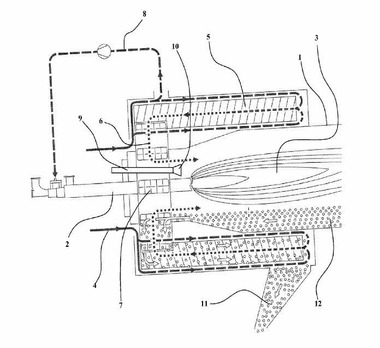

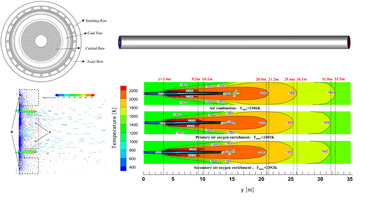

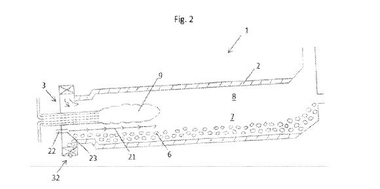

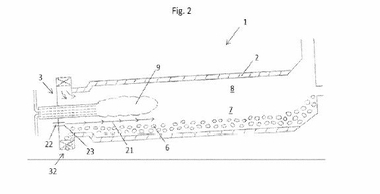

(57) A method for reducing combustion temperature and/or thermal radiation within a lime kiln of a pulp production plant, which kiln is a rotary kiln having a kiln tube (1) internally covered with refractory tiles (13) and having a burner (2) supplied by fuel for heating of the rotary kiln by a flame (3). The effects are achieved by supplying calcium carbonate containing particles to the flame (3) and/or to surrounding area around the flame (3). Preferably the particles are supplied into the rotary kiln by at least one lance (9) to the upper part of the flame (3). Calcium oxide containing particles may be supplied to the rotary kiln to areas surrounding the flame (3) for reducing the thermal radiation, preferably to area over the flame (3) and/or to the area at the side of the flame (3), where the refractory tiles (13) of the kiln are rotating downwards.

(71) Andritz Oy, Tammasaarenkatu 1, 00180 Helsinki (FI)