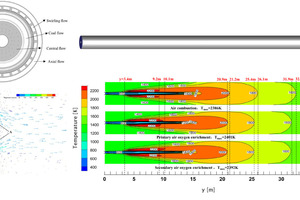

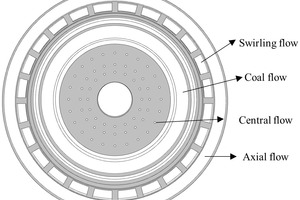

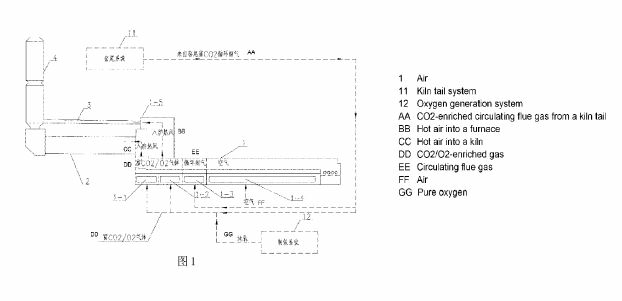

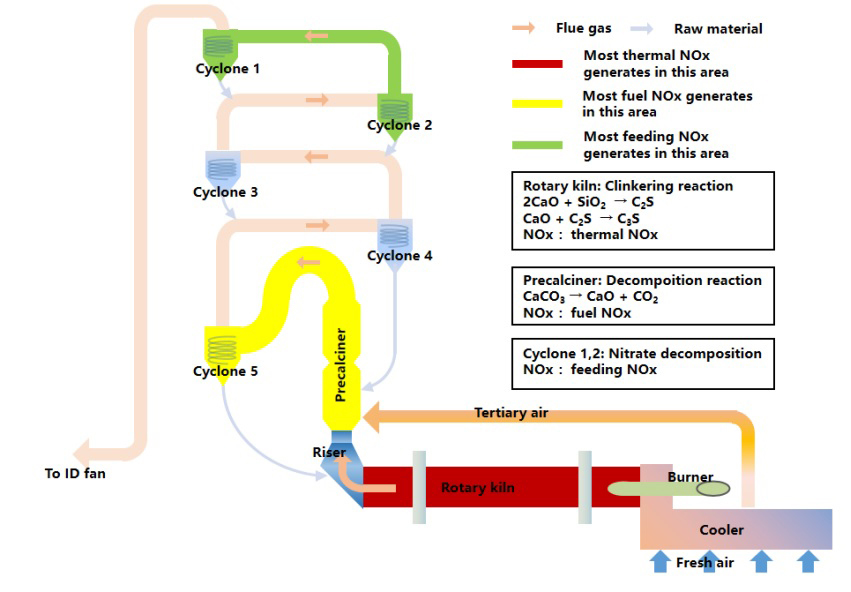

Numerical simulation of oxygen-enriched combustion in a rotary kiln in the primary air and the secondary air respectively

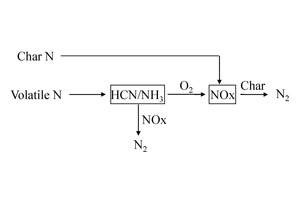

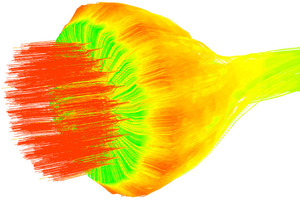

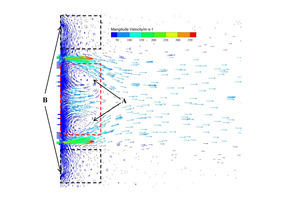

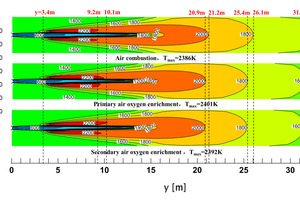

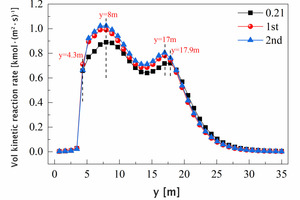

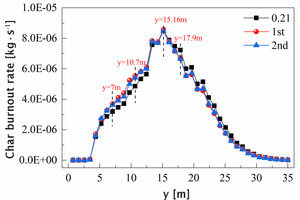

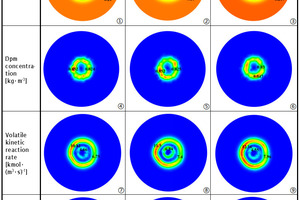

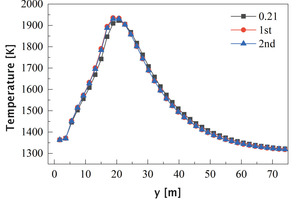

Aiming at a real-size rotary kiln, numerical simulations were carried out for air combustion, primary air oxygen enrichment, and secondary air oxygen enrichment conditions, respectively, in order to explore the influence of oxygen-enrichment methods on heat transfer and NOx generation in the rotary kiln. The results show that by using oxygen-enriched combustion

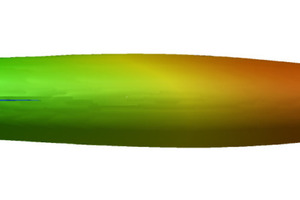

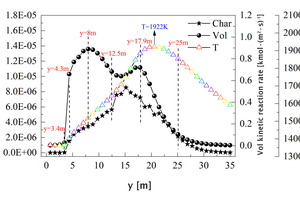

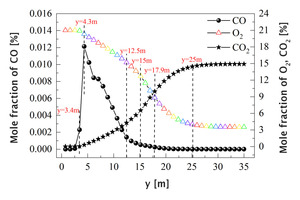

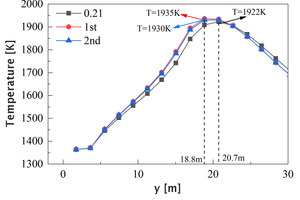

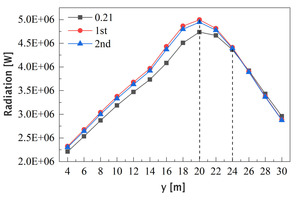

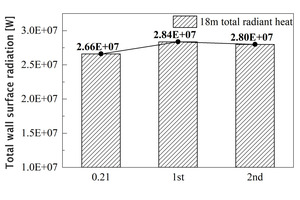

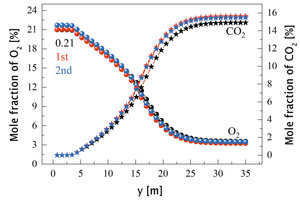

technology, the shape of the high temperature zone generated by the combustion is almost unchanged, in the shape of a willow leaf, and as the combustion rate of volatiles and char increases, the overall temperature of the flame increases, and thus the amount of radiation received by the wall surface of the rotary kiln also increases. Comparing the two oxygen enrichment methods, it can be found that the oxygen enrichment in the primary air results in the most obvious increase in average temperature, and the total radiation received by the wall surface in the burning zone is increased by about 6.76%, but the NOx generation is also increased significantly, with the NOx at the outlet increasing from 1099 ppm to 1303 ppm.

1 Introduction

China is a major cement producer and consumer. According to statistics, China produced 2.4 billion t of cement in 2020 [1]. The cement industry is also the main coal consumption and CO2 emission industry, it is the third top CO2 emitter industry in the world, responsible for 5% of global CO2 emissions [2], which brings great challenges with regard to the sustainable development of the cement industry. Therefore, improving the efficiency of pulverized coal combustion and reducing coal consumption and CO2 emissions have become urgent problems for the cement industry.

As an important...