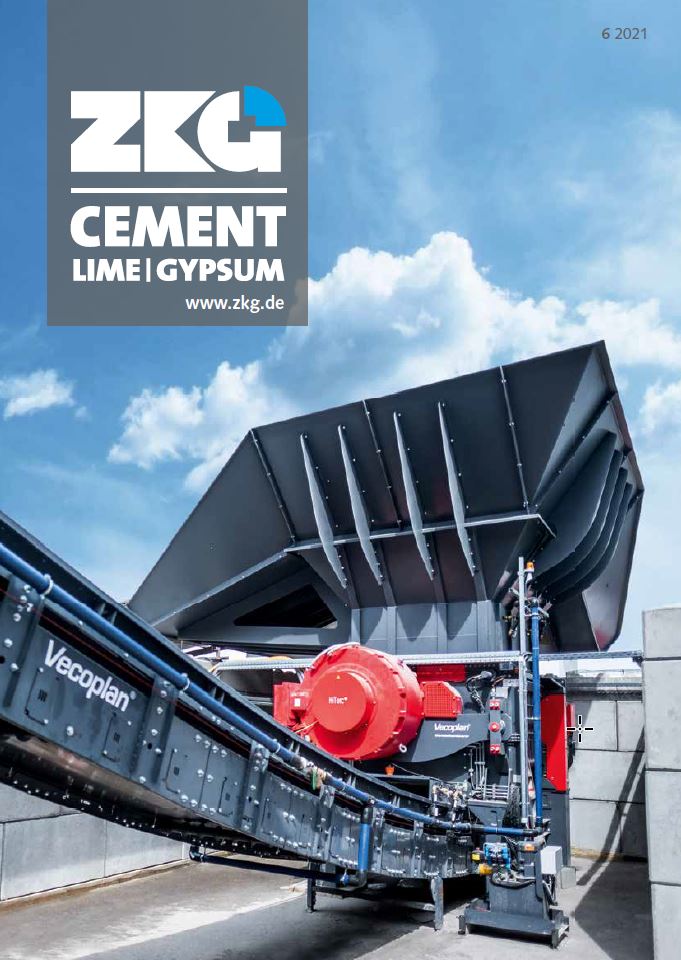

A processing line for flexible production of

refuse-derived fuels in different qualities – a case study of Helmut Westarp

For its customer Westarp in Aschaffenburg, Vecoplan implemented an efficient, flexible processing line for a wide range of high-quality refuse-derived fuels. In order to avoid interfaces and minimise its administrative costs, Westarp looked for a company that could provide a one-stop solution, from project planning to installation to commissioning. Vecoplan AG provided Westarp with two high-performance pre-shredders for feeding material to a plant with settings for various sorting and shredding requirements.

Introduction

Helmut Westarp GmbH & Co. KG is a midsize, family-operated waste management company based in Aschaffenburg/Germany. Founded in 1967, it initially focused on the collection and recycling of waste-paper, and has meanwhile expanded its operations to handle waste fractions of different kinds. Some 5000 customers from various industries in the Rhine-Main area rely on its services.

At its headquarters in Aschaffenburg Westarp processes surplus production material, bulk waste, large packaging material and unsorted commercial waste to generate refuse-derived fuel (RDF) of different qualities. This includes fractions with a medium calorific value for thermal utilisation in waste incineration plants and cement works. High-calorific waste supplies the main burners in cement works. At a certain point it became clear to the company that the existing processing line was no longer able to deliver the required performance. In addition, the line was not flexible enough to switch reliably between fuels of different quality.

In order to avoid interfaces and minimise its administrative costs, Westarp looked for a company that could provide a one-stop solution, from project planning to installation to commissioning. The choice fell on Vecoplan AG.

Based in Bad Marienberg/Germany, Vecoplan AG develops and manufactures machines and plants for processing alternative fuels derived from plastics, paper, domestic waste and commercial waste. At present it has about 500 employees worldwide. The company’s services include consultancy, finding effective solutions and detailed planning. Its integrated project management covers installation, commissioning and comprehensive service. Customers thus receive everything from a single source.

Vecoplan provided Westarp with two high-performance pre-shredders for feeding material to a plant with settings for various sorting and shredding requirements. For quality assurance the shredders were flanked by processes for removing ferrous and non-ferrous materials, several NIR separation processes and two air separators (2 and 3 fractions). Vecoplan also supplied the complete conveying equipment: trough conveyors, pendulum distributors, chain conveyors and double screw conveyors.

Tasks and requirements

Westarp needed an energy-efficient system with high availability and high output for generating refuse-derived fuels of high quality. It also wanted to be able to handle different kinds of fuels of different combustion quality. This new system had to be integrated into its existing processing line. Vecoplan therefore worked closely with the customer to design the system for both high performance and an ability to consistently generate different kinds of fuels.

Challenges

Vecoplan’s engineers had to take the existing layout at Westarp into account. The new machines had to be integrated into the company’s sorting systems. Space was limited, so Vecoplan carried out 3D measurements to determine an optimised setup. It first worked out the engineering details for the entire system. The machines were configured in advance to handle different kinds of input material and to generate high-quality output. Throughout the process of implementing the extensions and modifications, it was important to hold production downtimes to a minimum.

System description (Part 1, 2018)

Material is delivered to the different material flows mainly by Westarp’s transport service. Vehicles of other companies also contribute. The commercial waste has a bulk density of about 200 to 250 kg/m³, and for production waste the density is about 120 to 180 kg/m³. Employees pre-sort the material using grapples and wheel loaders and pass it to the pre-shredder, where it is reduced to a particle size of less than 200 mm. For this purpose, the company uses a VVZ 2500 double-shaft shredder supplied by Vecoplan, which continuously feeds material onto an adjoining conveyor belt. The belt passes an overbelt magnet for removal of ferrous material. A 3-fraction air separator then divides the material into heavy, medium and light fractions. The light fraction can be separated into high-calorific and medium-calorific fractions depending on the setting. The fractions can be adjusted by the company according to market requirements, and combined operation is also possible.

Another overbelt magnetic separator removes ferrous materials from the heavy fraction. The heavy material is then conveyed to a non-ferrous metal separator. Non-ferrous metals are removed by the eddy-current method and collected in a separate container.

The medium fraction generated by the air separator is also freed of ferrous metals, after which it is passed to a screen that removes pieces larger than 200 mm. This material is collected in a bin and delivered to the pre-shredder as needed. Residues from the sorting facility are also collected in the bin. Material smaller than 200 mm is deposited in a bin below it. Westarp supplies these medium-calorific refuse-derived fuels to customers for thermal utilisation.

The light fraction is likewise conveyed to an overbelt magnetic separator after air separation. The material then goes to re-shredding. A pendulum distributor evenly distributes it between two VEZ 2500 TT re-shredders, installed by Vecoplan. If one of these machines has to be serviced, Westarp can continue running the line with the other. The re-shredders reduce the light fraction to a particle size of less than 30 mm at throughput rates of 15 t/h per re-shredder. A drum magnet extracts further ferrous impurities from the re-shredded material. The result is high-calorific refuse-derived fuel which Westarp collects, unloads and transports to its customers. Most of the customers are cement works that use the material as a substitute for fossil fuels in their main burners. Westarp’s facility runs in two eight-hour shifts, five days a week.

High-performance re-shredding

Vecoplan developed the VEZ 2500 TT especially for RDF processing. This shredder is equipped with a high-performance cutting unit that is designed for maximum throughput and a very high level of technical availability. It is fitted with a patented W-rotor for maximum cutting performance. The 288 concave cutters are arranged in eight rows. Each knife can be used several times. Users benefit from uniform granularity, a long service life and low operating costs. Accessibility for maintenance is excellent. The re-shredder has two frequency-controlled synchronous HiTorc drives, each with a power of 247 kW and a 315 kW frequency converter. Energy savings of 20 to 30% compared to conventional motors are possible. The drives are noiseless, almost maintenance-free and can easily be started up with a full machine.

Extension of the system for greater flexibility (Part 2, 2021)

Vecoplan put the first part of the project into operation in April 2018. Not long after that, Westarp decided to increase its flexibility and meet the growing demand for refuse-derived fuels. In late 2020, it therefore commissioned Vecoplan AG to provide an extension.

The goal was to significantly increase the throughput to 50 t/h, ensure the flexibility of the system and have a good connection to the existing facility. For this purpose, Vecoplan installed an additional single-shaft pre-shredder from the VEZ 3200 series to generate material with a particle size of less than 250 mm. Ferrous material was then removed and an air separator created heavy and light fractions.

This new part of the facility now supplements the existing one and can be operated in three different modes.

Operating mode 1: Production of high-calorific RDF. After pre-shredding and separation of ferrous material, the light fraction is fed to the conveyor belt for re-shredding. After re-shredding it is processed to high-calorific RDF. The heavy fraction is then merged with the medium fraction from the existing facility and further processed

Operating mode 2: Production of medium-calorific RDF. After pre-shredding and separation of ferrous material, the material is conveyed to the heavy fraction of the air separator and merged with the medium fraction of the existing facility, where it is further processed

Operating mode 3: Material supply to the sorting facility. After pre-shredding and separation of ferrous material, the material is fed to a separate belt conveyor via the heavy and light fraction of the air separator of the sorting facility for further processing. The sorting facility can process a wide range of materials for recycling

Thanks to this extension, Westarp has a highly flexible system. It is able to handle a wide variety of input materials and can respond to varying requirements placed on the output.

Summary

Westarp GmbH & Co. KG has received a state-of-the-art processing line with high-tech components. This project has enabled the company to benefit from a fully optimised, integrated system with high output quality and profitability. The equipment for pre- and re-shredding of material for production of RDF is robust from end to end, insusceptible to extraneous material and optimised for low maintenance. The level of availability is high and energy consumption is low.

Vecoplan supplied everything for this project from a single source – from project management to assembly to commissioning. It installed the electrical equipment, conveyors, separators, sorters and the steel structure. The new processing facility enables Westarp to produce RDF in different fractions and respond flexibly to changing market conditions.