Application performance research of the NU classifier in industrial production

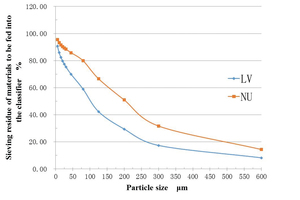

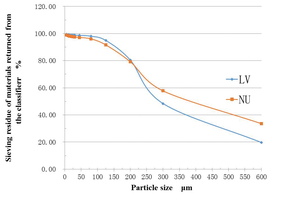

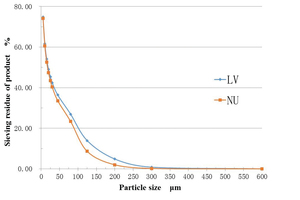

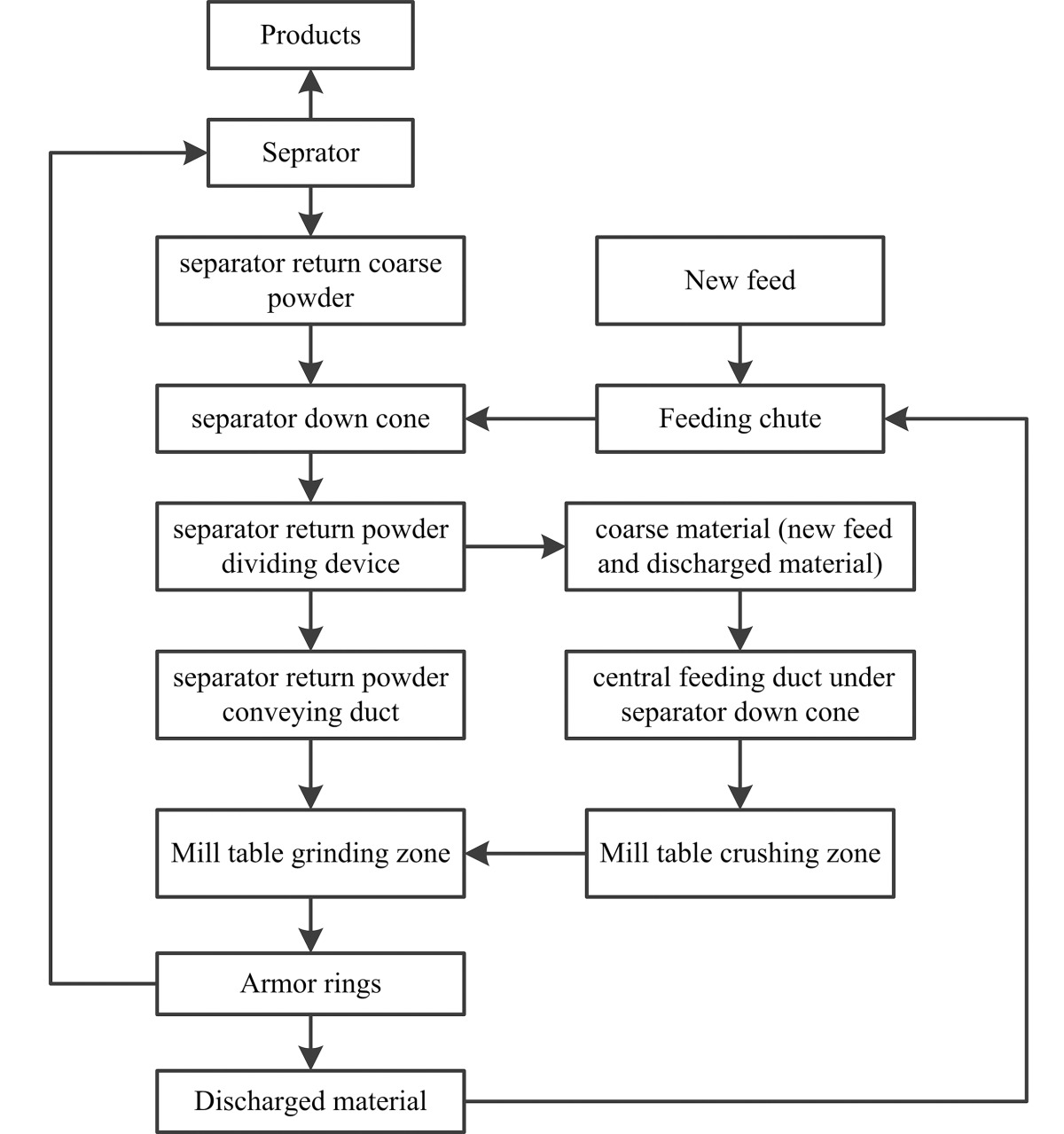

Based on the process layout characteristics of a classifier in a vertical roller mill, a method is firstly studied and designed to research and test a vertical roller mill classifier’s performance. Secondly, the NU 5026 classifier’s performance, such as main motor power consumption, pressure loss, classifying efficiency, product fineness etc., is studied in detail, which is carried

out in the Yu Zhou Ling Wei Line 2 MLS3626 vertical roller mill that was contracted by TCDRI in a technology update project. In order to compare the NU classifier’s performance with other classifiers, the LV5021 classifier that is used in the Yu Zhou Ling Wei Line 1 MLS3626 vertical roller mill is simultaneously tested. Finally, the conclusion drawn is that the NU classifier has clear advantages over a common classifier in respect of main motor power consumption, pressure loss, classifying efficiency, product fineness etc., which provides a good technology scheme for energy saving and consumption reduction in the cement industry.

1 Introduction

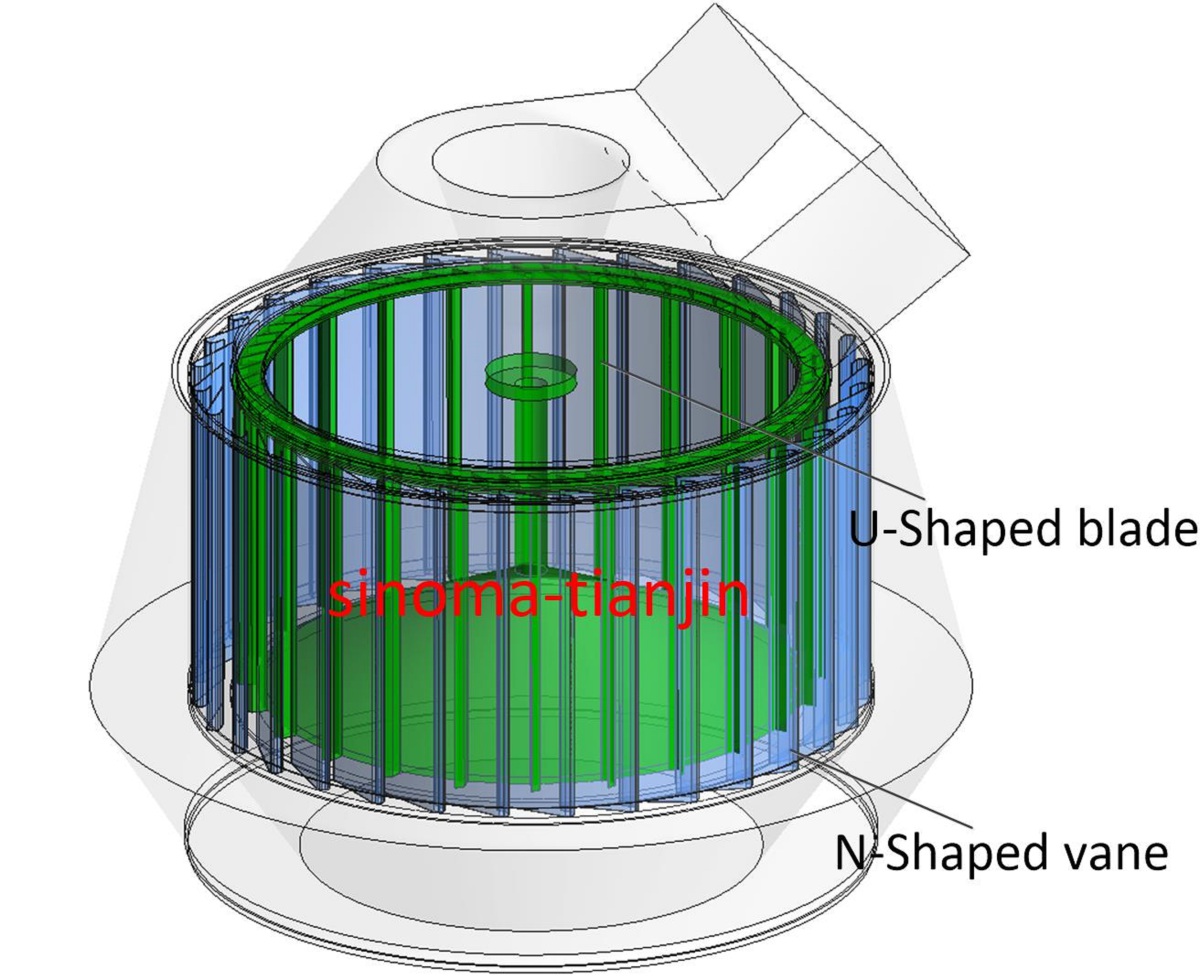

The classifier is a core device in a recirculation grinding system, and has a great influence on product quality, output and power consumption. In order to reduce the power consumption of a grinding system and improve the product quality, the classifier has been thoroughly studied at home and abroad [1-5]. The classifier with U shape blades is the first generation of centripetal classifier originally proposed and developed by the Tianjin Cement Industry Design and Research Institute Co., Ltd., and is based on a large number of CFD theoretical studies [6-11]. Because the moving...