Better dosing to the coal mill

1 Development

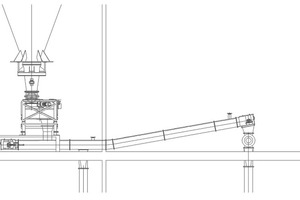

Holcim Spain started a project at their Carboneras plant (Fig. 1) to improve the pet-coke grinding performance in order to obtain safe and reliable coal mill feeding and to improve the coal mill grinding performance. The start-up of this installation took place in 2010. With rotor weighfeeder Pfister® TRW-K FLSmidth Pfister GmbH from Augsburg, Germany supplied the dosing equipment to the coal mill.

The project included the replacement of the old raw coal feeding equipment to the mill, which consisted of an apron feeder, for the new design of rotor weighfeeder Pfister® TRW-K. This...