FLSmidth Pfister launches new rotor weighfeeder model for hot gas generators

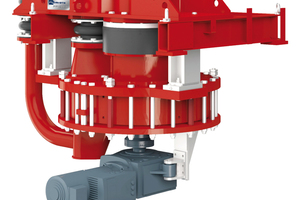

Smaller in size but just as capable and accurate as its big brothers is the latest rotor weighfeeder model that German FLSmidth Pfister, specialist for weighing and dosing technology in cement, launched lately. Rotor weighfeeder Pfister DRW 4.08 was especially designed for dosing pulverized fuels to hot gas generators (HGG).

The system is typically employed with hot gas generators (HGG) operating with solid fuels like coal dust. Considering fuel costs, coal-fired hot gas generators (HGG) are an interesting alternative to oil- and gas-fired HGGs and employed by more and more cement manufacturers. These HGGs are typically heated with coal dust, lignite dust or petcoke, all materials for which rotor the weighfeeder Pfister DRW 4.08 is laid out for.

The rotor weighfeeder Pfister DRW 4.08 is based on the industry-wide proven Pfister gravimetric rotor weighfeeder technology which supports stable, reliable and accurate fuel dosing to the burners. Sturdy design and integration of material extraction, weighing, dosing and material transfer into a pneumatic conveying line make it a compact system. The dosing capacity of one system ranges from 0.2-5.0 t/h. State-of-the-art electronics realize not only high short- and long-term accuracy and dosing stability but also contribute to low levels of CO.

//www.flsmidthpfister.com" target="_blank" >www.flsmidthpfister.com:www.flsmidthpfister.com