Better thermal kiln monitoring

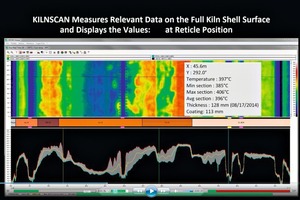

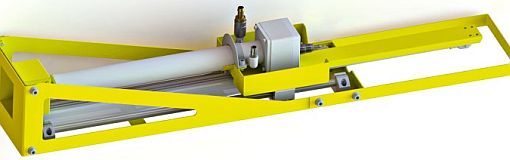

HGH Infrared Systems, based in Paris, France, has released an improved generation of thermal scanning equipment. The new infrared scanner named “Kilnscan” monitors rotary kiln shell temperature, continuously, in real-time, with a high spatial and thermal resolution and definition. By providing early warning of failures, the device improves kiln efficiency and its long-term reliability. It contributes to increasing production rates, reducing operating costs, improving the burning process, and saving energy.

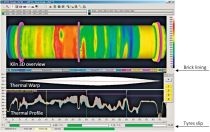

With a highest spatial and thermal resolution, Kilnscan keeps permanent surveillance on each individual refractory. It tracks hot spots, tyre slippage, rings formation, brick losses and thermal warp to prevent irreversible damage. With more than 1000 units in operation around the world, HGH thermal scanners are used in most cement plants to warn of potential failures and trigger preventive actions.

Features are:

High spatial resolution to detect single brick failure

High thermal sensitivity to warn of any suspect temperature change

Automatic calibration with internal blackbody: no drift over time

Unique scan angle, up to 140°, to scan long shell

Unique external reference blackbody for unsurpassed accuracy in adverse weather conditions

Fibre optic link to the control room to avoid electromagnetic interferences

Rugged system, designed for demanding environments

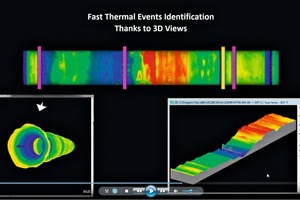

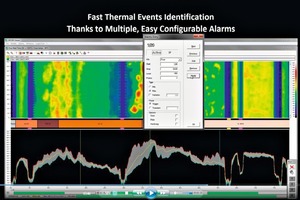

On control room screens and maintenance team workstations, Kilnscan software takes advantage of the Kilnscan’s very accurate measurements, to display at a glance all necessary information to preserve kiln shell integrity. In addition, thanks to valuable and unique features, Kilnscan software enables analysis on a long-term basis and reliable trend drawing. Real-time 3D thermal profile and brick and coating thickness are parts of the package as well as an advanced refractory management, the control of kiln rotating speed and heat loss calculation. The included software allows OPC server & client configurations, multiple alarms management and cooling fans control. An automatic data recording and historical data management are instruments to monitor events evolution.

//www.hgh-infrared.com" target="_blank" >www.hgh-infrared.com:www.hgh-infrared.com